A normal temperature fermented milk beverage and its preparation method

A milk-containing drink, fermented at room temperature technology, applied in dairy products, milk preparations, applications, etc., can solve the problem of short shelf life of low-temperature brown lactic acid bacteria drinks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

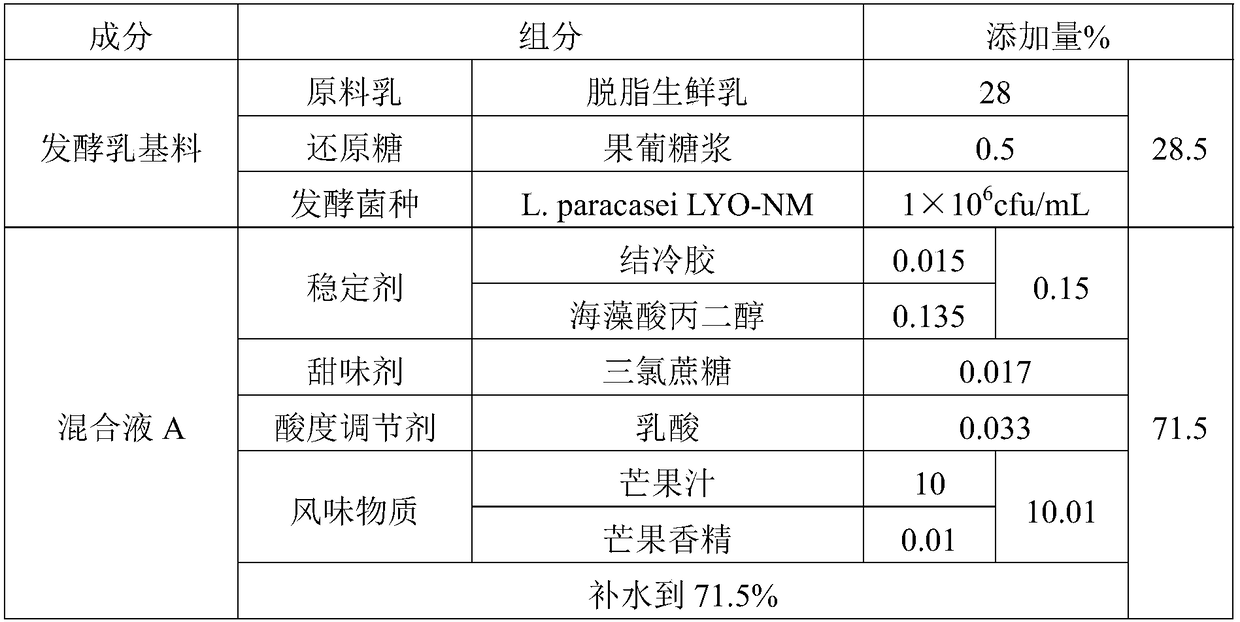

[0030] Table 1

[0031]

[0032] (1) Mix the raw milk (the protein content of skimmed fresh milk is 2.5g / 100g, and the fat content is 0.49 / 100g) and reducing sugar at 39°C for 15 minutes to obtain a mixed solution, and keep the mixed solution at 90°C for 1.5 hours , natural browning reaction to obtain browning feed liquid;

[0033] (2) cooling the browning feed liquid to 36°C, inoculating a starter and probiotics for fermentation, fermenting at 36°C for 60 hours until the acidity is 160°T, cooling to below 4°C, and obtaining a fermented milk base;

[0034] (3) Mix the mixed liquid A with the fermented milk base material according to the ratio of 71.5:28.5 (W / W), homogenize at 15Mpa at the first level, homogenize at 4°C, and fill in the Baili bag. 95%, and 300Mpa under the condition of 10 DEG C for 3 minutes to obtain a normal temperature fermented milk beverage. The mixed liquid A is composed of sweetener, stabilizer, acidity regulator, flavoring substance and water. It i...

Embodiment 2

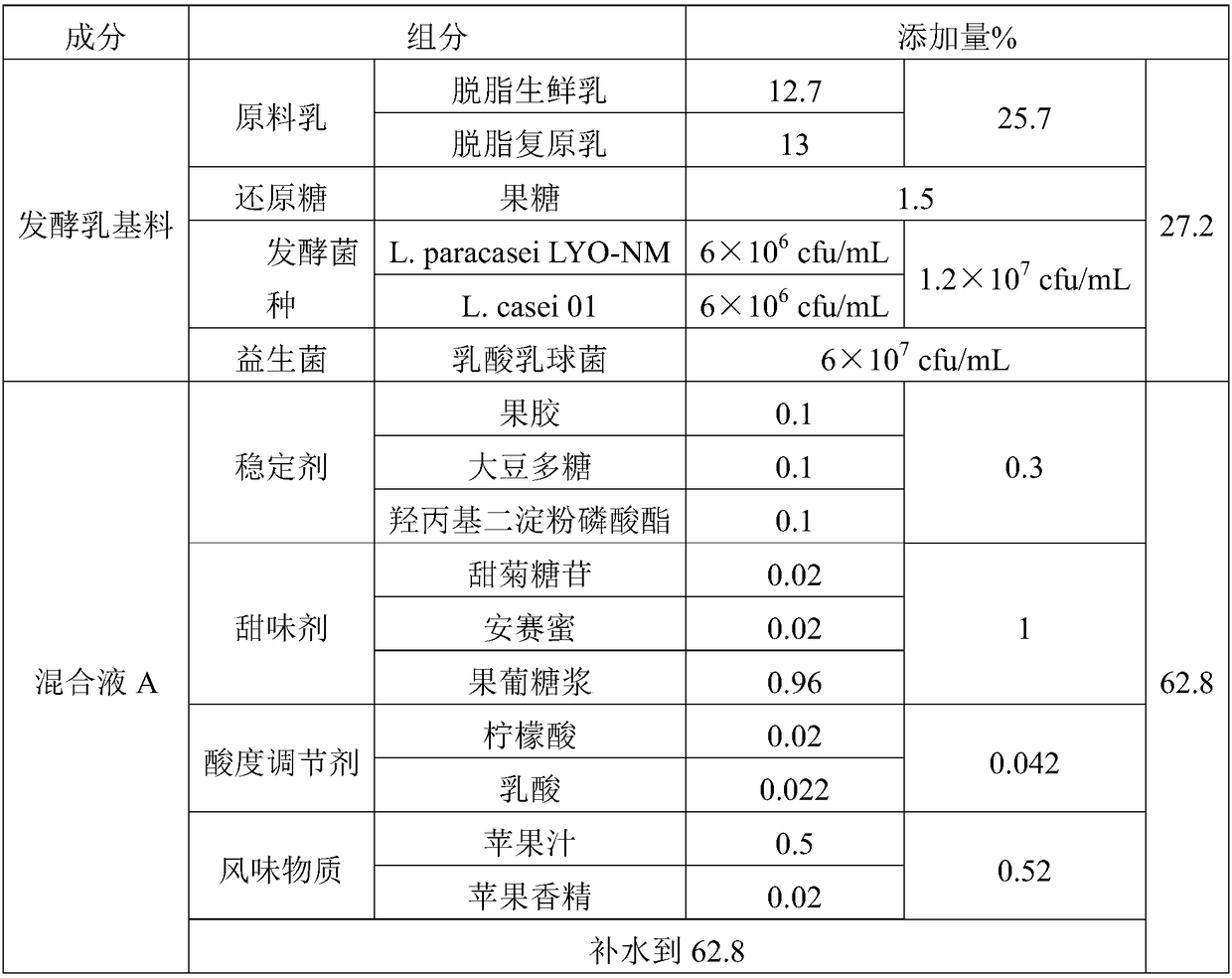

[0038] Table 2

[0039]

[0040] (1) Mix raw milk (both skimmed fresh milk and skimmed reconstituted milk have a protein content of 3.5g / 100g and a fat content of 0.2 / 100g) and reducing sugar at 45°C for 20 minutes to obtain a mixed solution, which is then heated at 91.5°C Next, heat preservation for 1.9 hours, natural browning reaction, obtain browning feed liquid;

[0041] (2) cooling the browning feed liquid to 37°C, inoculating starter and probiotics for fermentation, fermenting at 37°C for 71 hours until the acidity is 180°T, cooling to below 12°C, and obtaining the fermented milk base;

[0042] (3) Mix the mixed solution A with the fermented milk base material according to the ratio of 62.8:27.2 (W / W), go through a first-stage 17Mpa homogenization at 12°C, and fill it into a PET prefabricated bottle with a filling volume of 96%. Treat at 400Mpa for 4 minutes at 12°C to obtain a normal temperature fermented milk beverage. The mixed liquid A is composed of sweetener, ...

Embodiment 3

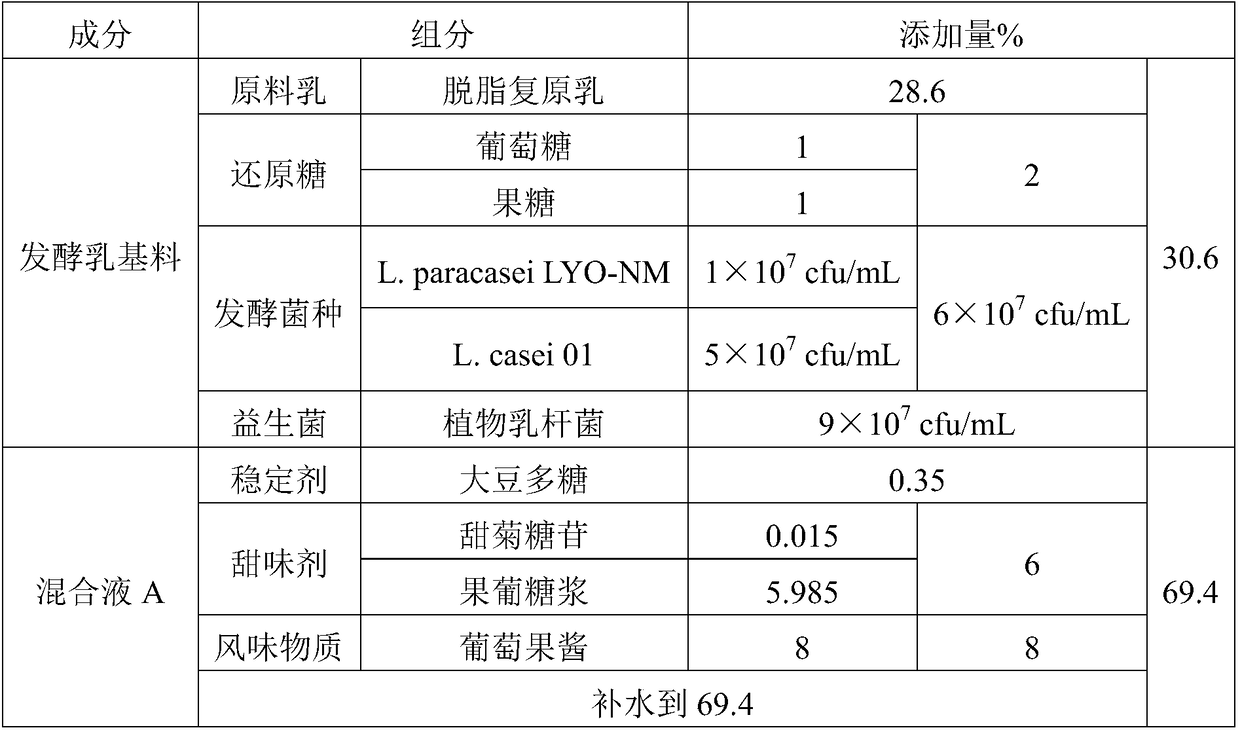

[0046] table 3

[0047]

[0048] (1) Mix raw milk (protein content 3.5g / 100g, fat content 0.2 / 100g) and reducing sugar at 50°C for 22 minutes to obtain a mixed solution, and keep the mixed solution at 92°C for 2.0 hours to naturally brown React to obtain browning feed liquid;

[0049] (2) Cool the browning feed liquid to 37.5°C, inoculate the starter and probiotics for fermentation, ferment at 37.5°C for 71.2 hours until the acidity is 190°T, cool to below 15°C, and obtain the fermented milk base;

[0050](3) Mix the mixed liquid A with the fermented milk base material according to the ratio of 69.4:30.6 (W / W), at 15°C, go through the first-level homogenization of 17Mpa, the second-level homogenization of 3Mpa, and fill it in Tetra Pak TT tank , the filling volume is 96.5%, and it is treated at 400Mpa for 4 minutes under the condition of 20°C to obtain a normal temperature fermented milk beverage. The mixed liquid A is composed of sweetener, stabilizer, flavoring substanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com