Pole piece cooling clearance for axial motors

A technology for electric motors, axial flux, applied in cooling/ventilation units, salient poles, synchronous motors with stationary armatures and rotating magnets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

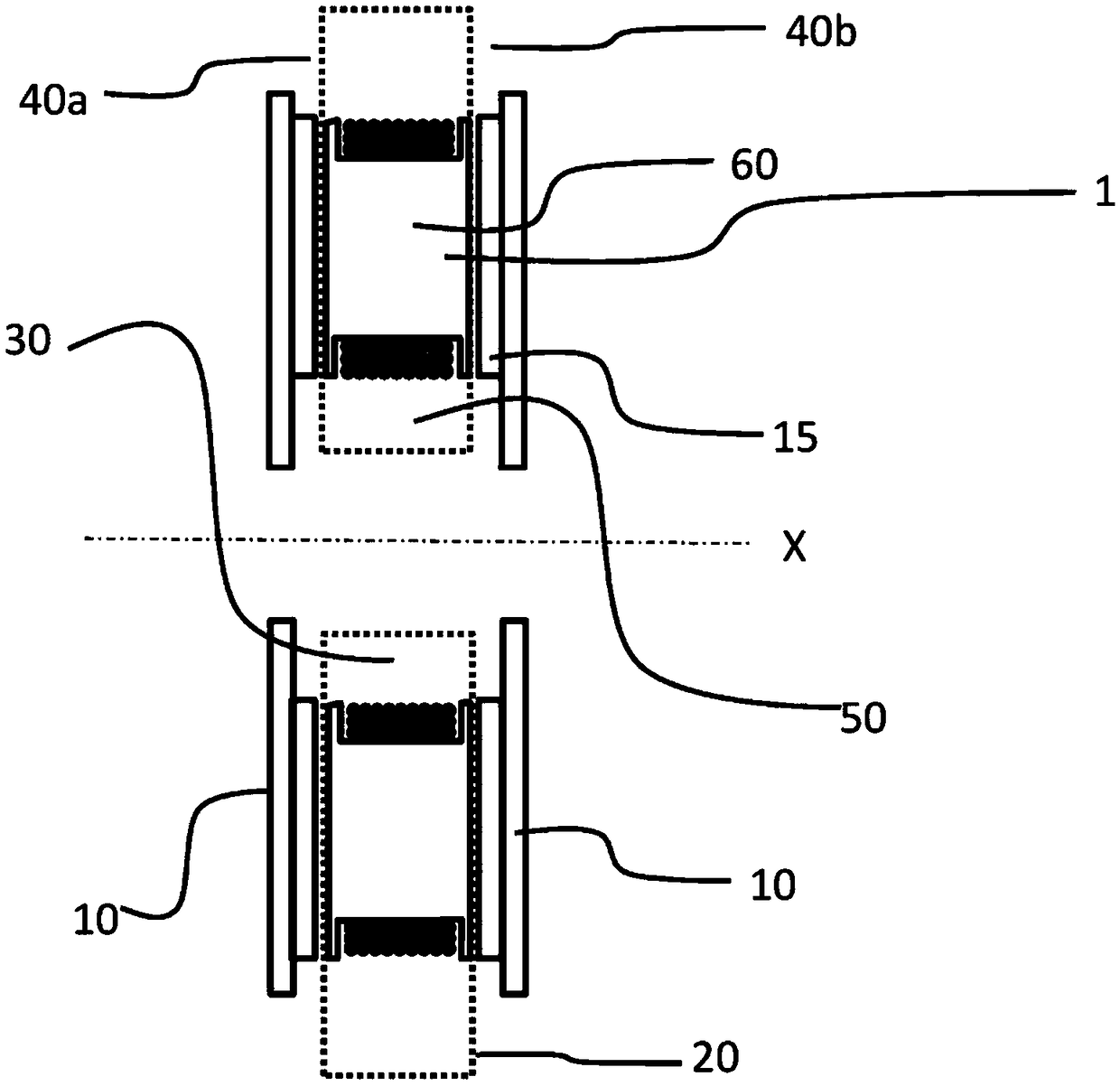

[0037] reference figure 1 , The stator of the dual-rotor yoke-less segmented armature motor is made of a plurality of electromagnetic coils 50. Each electromagnetic coil 50 includes pole pieces 60 and associated coils 55 distributed in the cavity 30 in a clockwise direction. 30 has cavity walls 40a and 40b, and the coil 55 is connected together and powered by an external power source (not shown) to generate a magnetic field rotating around the coil. Either end of the electromagnetic coil interacts with a plurality of permanent magnets 15 mounted on the rotor 10 in a clockwise direction. After that, the magnet and the rotor passively rotate from one pole position to the adjacent pole position by the action of the rotating electromagnetic field, and the rotor 10 rotates around the X axis. The stator cavity 30 includes a liquid coolant that circulates between the electromagnetic coils to remove heat, and transfer the heat outward to the motor, and finally to a radiator (not shown)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com