Method for determining the state of the tap of metallurgical vessel in particular

A metallurgical furnace and valve technology, which is applied in the field of valve status, can solve the problems of comprehensive determination of furnace lining, etc., and achieve the effect of optimizing refractory lining and optimizing process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

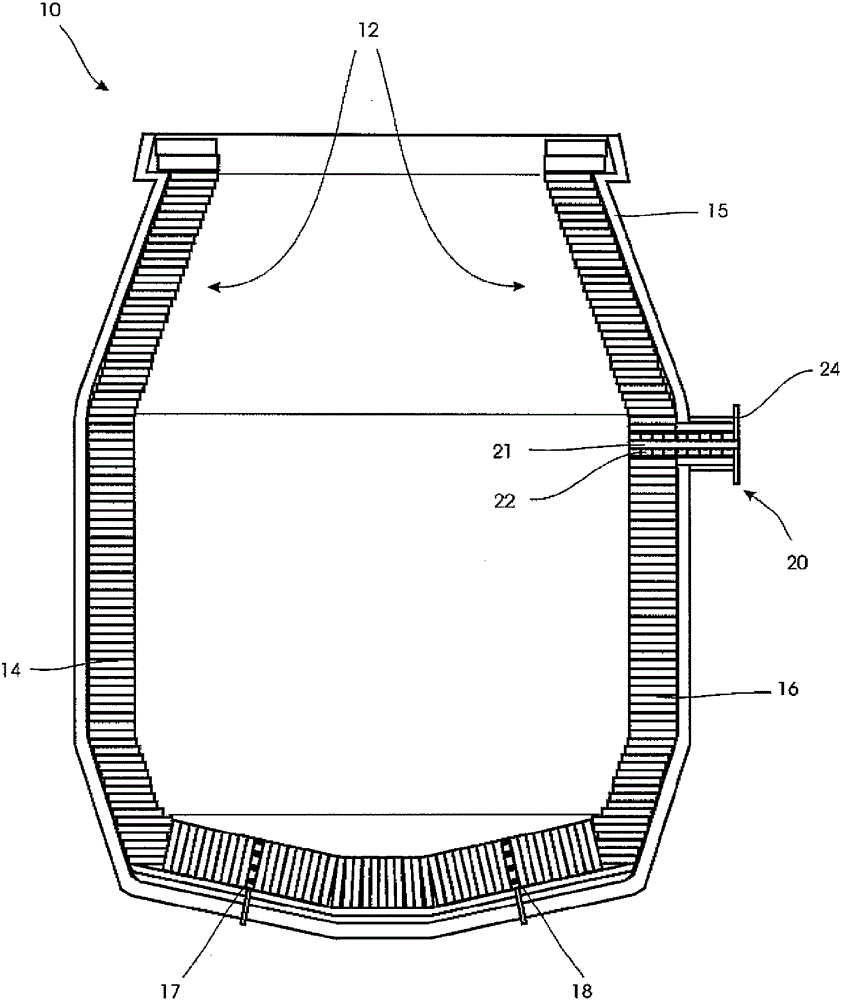

[0012] The method relates in particular to metallurgical furnaces. As an exemplary embodiment, the cross-section of one such furnace 10 is at figure 1 shown in . In this example, the furnace is a converter 10 known per se for the production of steel. The converter 10 basically consists of a metal shell 15, a refractory lining 12, valves 20 and gas sweep plugs 17, 18 which can be coupled to a gas supply (not detailed).

[0013] The molten metal poured into said converter 10 in operation is metallurgically treated, for example, by blowing (it will not be detailed here). Typically, several of said converters 10 are used simultaneously in a steelworks to produce steel, and data for each converter will be recorded.

[0014] The valve 20 is arranged in a side area of the converter 10 and is used to discharge the molten metal which has been processed. The valve 20 is composed of a valve passage 21 , a sleeve-shaped valve block 22 forming the valve passage, and a metal discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com