Variable damping force damper

A damping force and shock absorber technology, which is applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve problems such as reduced responsiveness, weak magnetic force, and reduced vehicle comfort, and achieve staged changes inhibitory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings as appropriate.

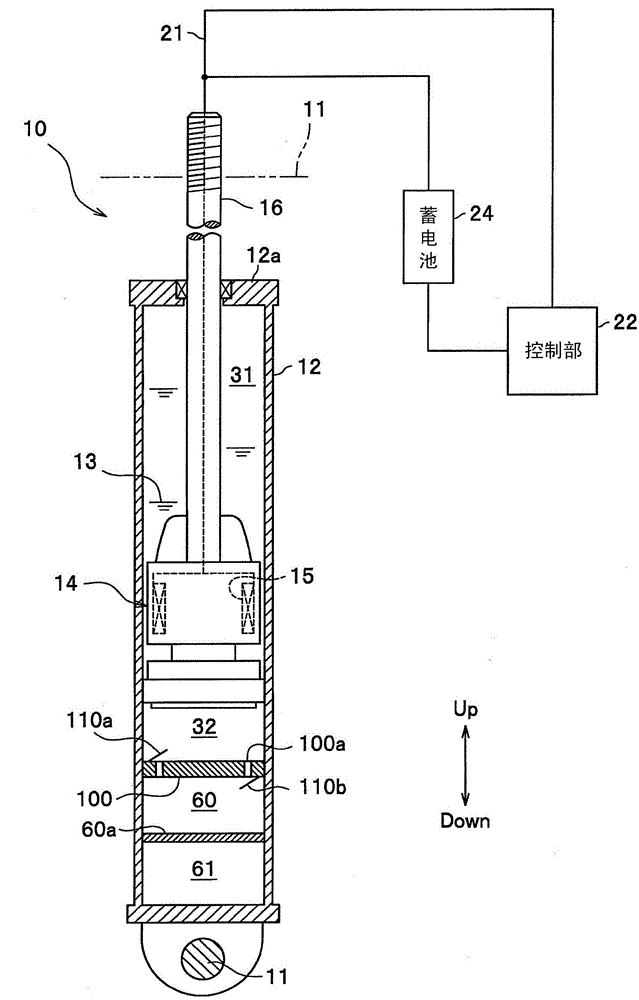

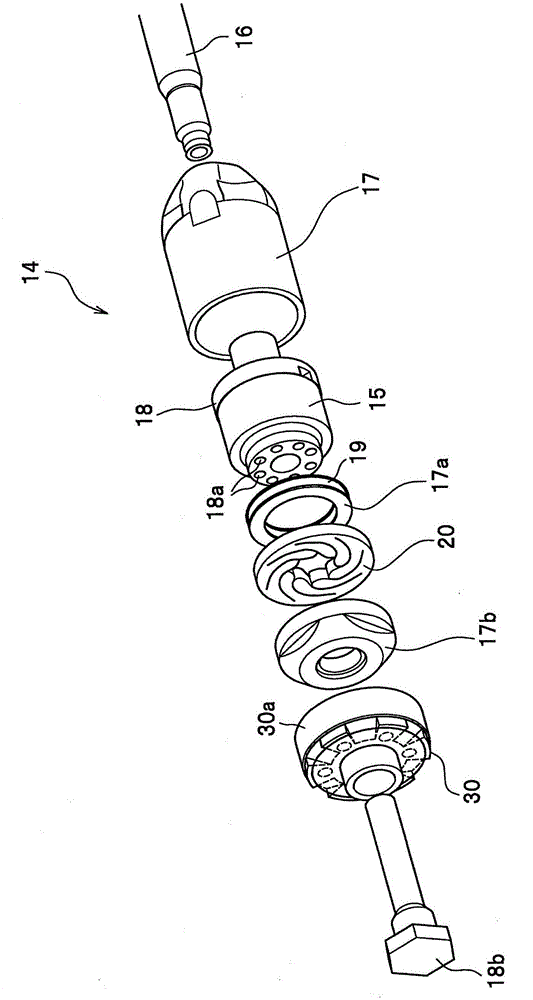

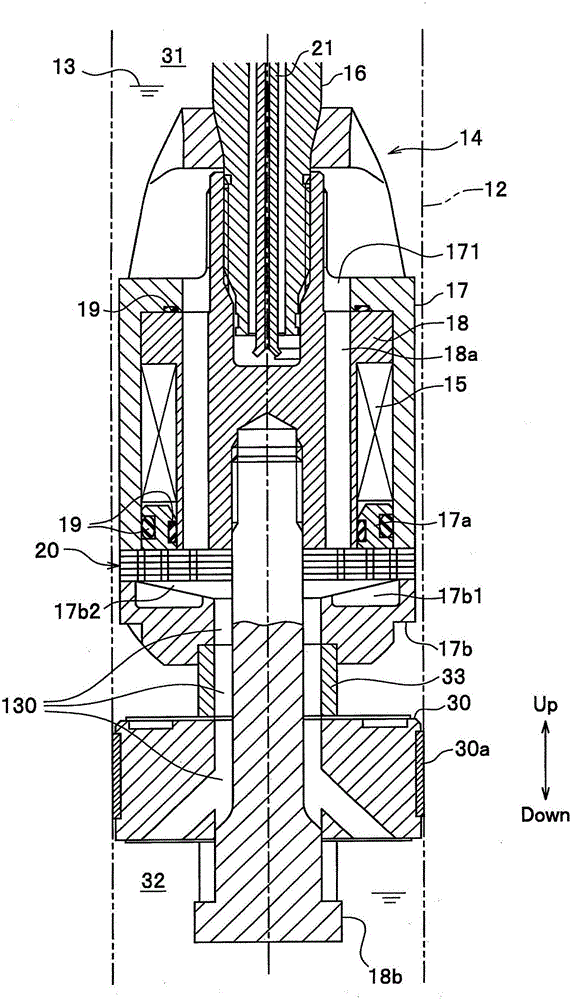

[0033] figure 1 is the structural diagram of the damping force variable shock absorber, figure 2 is a perspective view showing the structure of the piston assembly, image 3 is a cross-sectional view of the piston assembly.

[0034] Such as Figure 1~3 As shown, the damping force variable shock absorber 10 of this embodiment is a shock absorber that actively changes the damping force to absorb vibrations generated in the vehicle 11 .

[0035] The variable damping force damper 10 includes: a cylindrical hydraulic cylinder 12; a piston assembly 14 slidably accommodated in the hydraulic cylinder 12; The piston rod 16.

[0036] In this embodiment, the vertical direction (Up, Down) of the damping force variable damper 10 is set with the side of the upper end portion 12a protruding from the piston rod 16 being upward (Up).

[0037] In addition,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com