Air spring, in particular for vehicles

一种空气弹簧、车辆的技术,应用在车辆弹簧、弹簧、车辆部件等方向,达到成本低廉的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

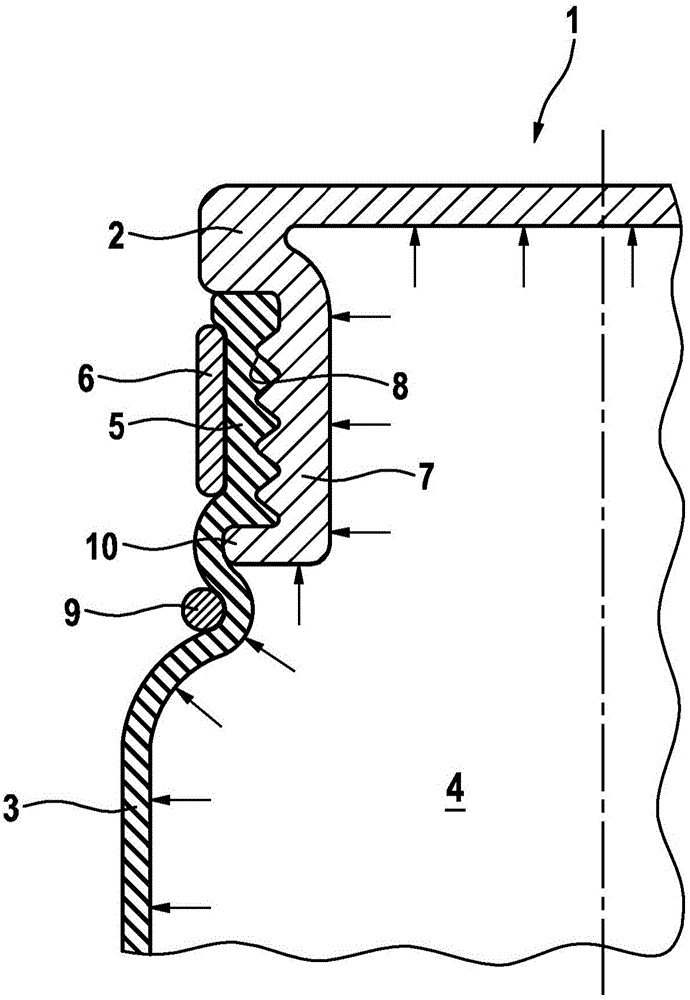

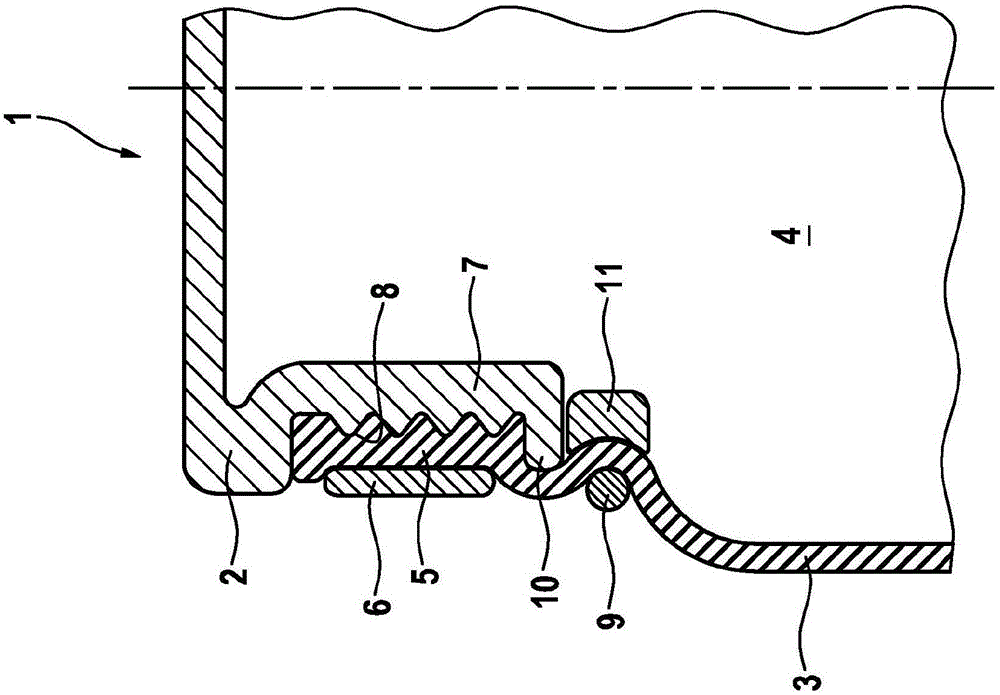

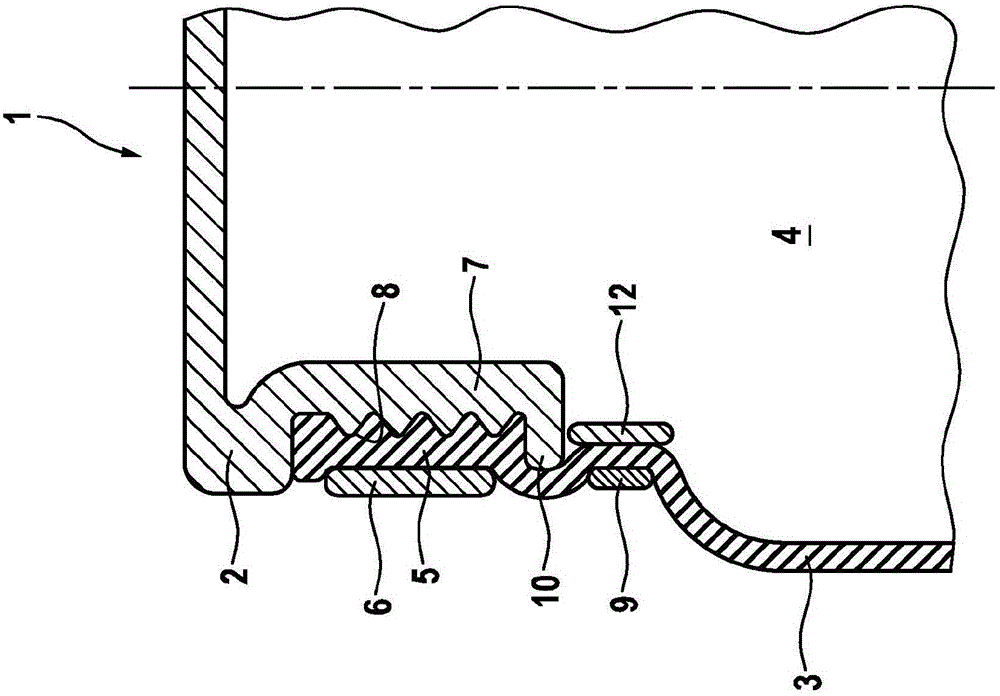

[0021] figure 1 Shown schematically and in section is a detail of a first exemplary embodiment of an air spring 1 , which is tensioned between the chassis and the body of a motor vehicle with an air spring piston (not shown) and an air spring cover 2 .

[0022] The air spring 1 has an air spring bellows 3 made of an elastomer material, which at least partially delimits a working chamber 4 filled with compressed air, which is fixed sealingly on the air spring cover 2 and on the air spring piston. , and the air spring airbag rolls over the air spring piston forming at least one unshown rolling fold.

[0023] As can be seen in the figure, an end region 5 of the air spring bellows 3 is fastened to the clamping section 7 of the air spring cover 2 by means of a snap ring 6 . The clamping connection between the air spring bellows 3 and the air spring cover 2 is strongly loaded by the internal overpressure in the working chamber 4 of the air spring 1 and the resulting forces indicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com