Laminated glass

A technology for laminated glass and glass substrates, applied in windshields, coatings, glass/slag layered products, etc., can solve the problems of difficulty in having both, reduced light transmittance, and reduced infrared reflectivity, and achieves infrared reflection. Excellent in rate and light transmittance, and the effect of suppressing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0192] (4-3) Preparation method of coating liquid

[0193] The method of preparing the coating solution for the high refractive index layer and the coating solution for the low refractive index layer is not particularly limited, for example, adding a water-soluble binder resin, metal oxide particles, and other additives added as needed, and stir to mix. At this time, the order of adding the water-soluble binder resin, metal oxide particles, and other additives used as needed is not particularly limited, and each component may be added sequentially while stirring, or may be added and mixed at once while stirring. If necessary, a solvent may be further used to obtain an appropriate viscosity.

[0194]In the present invention, it is preferable to form the high refractive index layer using an aqueous high refractive index layer coating solution prepared by adding and dispersing core-shell particles. In this case, the core / shell particles are preferably prepared by adding to the ...

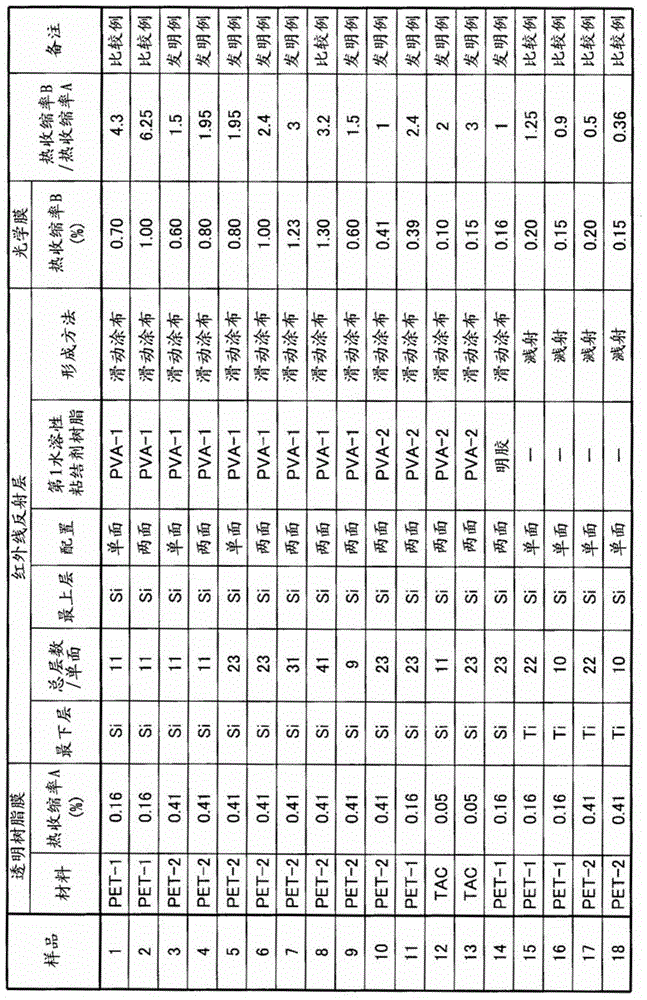

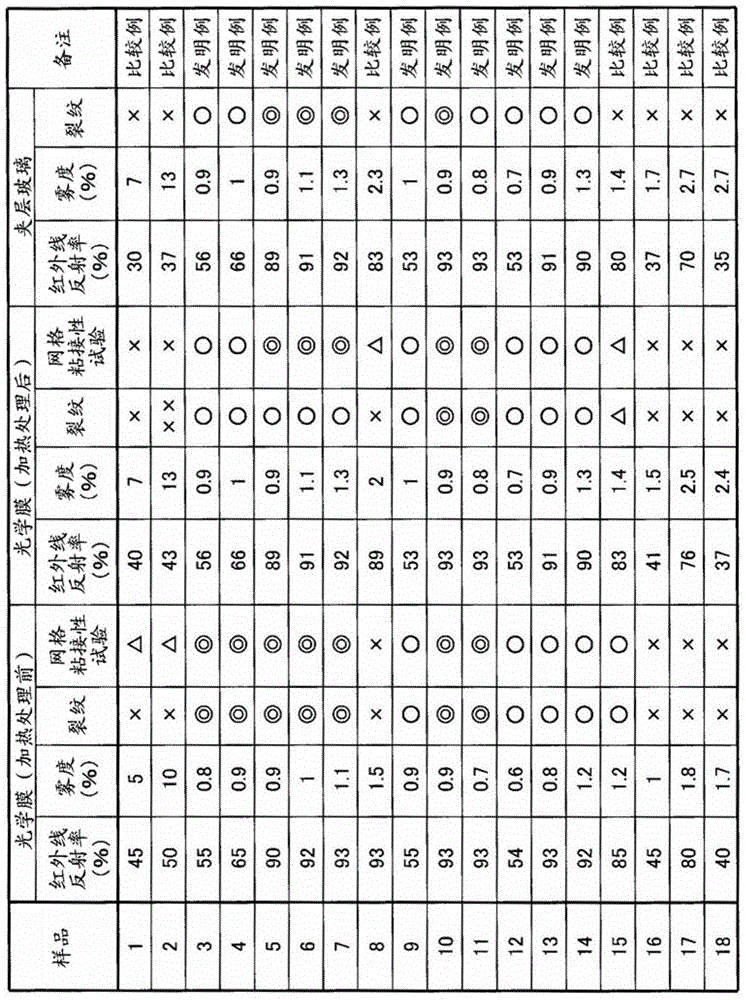

Embodiment

[0284] Hereinafter, although an Example is given and this invention is demonstrated concretely, this invention is not limited to these Examples. In addition, the expression of "%" is used in an Example, Unless otherwise specified, it means "mass %".

[0285] "Making of Laminated Glass 1"

[0286] (Preparation of Coating Liquid L1 for Low Refractive Index Layer)

[0287] First, 680 parts of an aqueous solution of 10% by mass of colloidal silica (manufactured by Nissan Chemical Industry Co., Ltd., SNOWTEX (registered trademark) OXS) as the second metal oxide particles, 4.0% by mass of polyvinyl alcohol (manufactured by Kuraray Co., Ltd. , PVA-103: 300 parts of polymerization degree, 98.5 mol% of saponification degree) aqueous solution, and 150 parts of 3.0 mass % boric acid aqueous solution were mixed and dispersed. Pure water was added to prepare 1000 parts of colloidal silica dispersion liquid L1 as a whole.

[0288] Next, the obtained colloidal silica dispersion L1 was hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com