Thermal superconducting sheet heat sink and manufacturing method thereof

A technology of superconducting sheet type and manufacturing method, which is applied in other manufacturing equipment/tools, manufacturing tools, cooling/ventilation/heating transformation, etc., and can solve the problem of complex liquid cooling radiator system, inability to meet heat dissipation requirements, and low efficiency of heat sink and other issues, to achieve the effect of convenient and flexible manufacturing, light weight and uniform heat distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

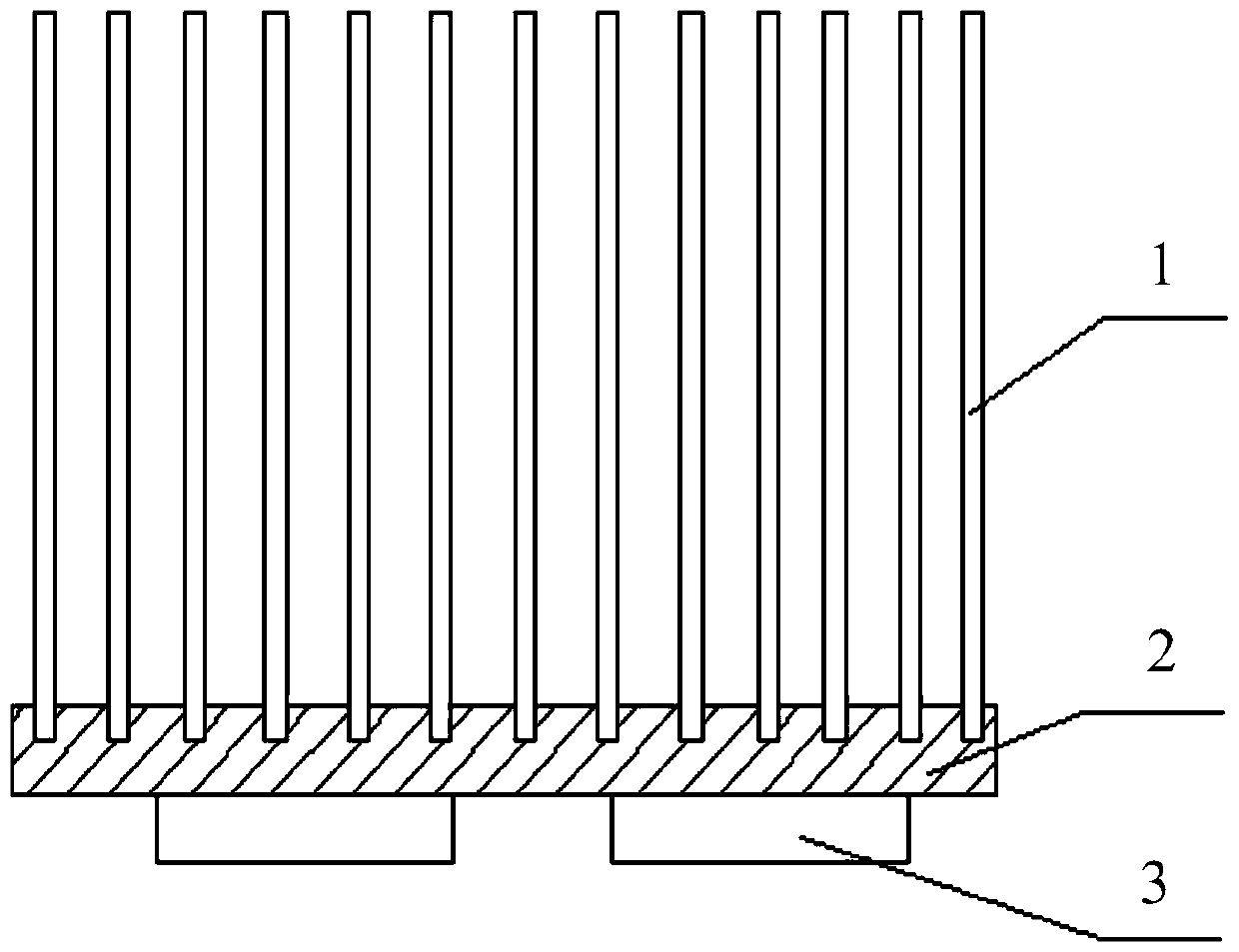

[0061] see Figure 1 to Figure 6 , the present invention provides a thermal superconducting fin radiator, the thermal superconducting fin radiator includes a radiator substrate 2 and a plurality of thermal superconducting fins 1 inserted on the radiator substrate 2; The thermal superconducting heat dissipation fin 1 includes two plates 11 that are composited together by a rolling process, and a closed pipe 12 that communicates with each other and has a certain structural shape is arranged between the two plates 11, and the closed pipe 12 It is filled with heat transfer working fluid 14 .

[0062] As an example, a groove (not shown) is provided on the heat sink substrate 2, and the side walls of the groove are perpendicular to the surface of the heat sink substrate 2; Vertically inserted into the groove, and the thermal superconducting fins 1 are fixedly connected to the heat sink substrate 2 through a mechanical extrusion process, a thermally conductive adhesive bonding proce...

Embodiment 2

[0075] see Figure 7 , the present invention also provides a thermal superconducting fin radiator, the structure of the thermal superconducting fin radiator described in this embodiment is roughly the same as that of the thermal superconducting fin radiator described in Embodiment 1, The difference between the two is: the thermal superconducting heat dissipation fins 1 in Embodiment 1 are vertically inserted into the heat sink substrate 2, while in this embodiment, the thermal superconducting heat dissipation fins 1 are obliquely inserted into the heat dissipation inside the device substrate 2.

[0076] As an example, the method of obliquely inserting the thermal superconducting heat dissipation fins 1 into the heat sink substrate 2 may be to first adopt the solution in Embodiment 1, and set a side wall on the heat sink substrate 2 perpendicular to the heat dissipation grooves on the surface of the device substrate 2, and insert the thermal superconducting fins 1 vertically i...

Embodiment 3

[0081] see Figure 8 , the present invention also provides a manufacturing method of a thermal superconducting fin radiator, the manufacturing method comprising:

[0082] S1: providing a heat sink substrate, and opening a groove on the heat sink substrate;

[0083] S2: The thermal superconducting heat dissipation fins are manufactured by the inflation process, and the closed pipes connected with each other and having a certain structural shape are formed inside the thermal superconducting heat dissipation fins, and a certain amount of heat transfer working fluid is filled in the closed pipes ;

[0084] S3: Insert one end of the thermal superconducting heat dissipation fin into the groove, and connect the thermal superconducting heat dissipation fin to the heat dissipation The device substrate is fixedly connected.

[0085] Execute step S1, see Figure 8 In the S1 step, a heat sink substrate is provided, and grooves are opened on the heat sink substrate.

[0086] As an exa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com