Flexible film solar cell packaging method and solar cell

A technology for solar cells and solar cell sheets, applied in the field of solar cells, can solve the problems of damage, high rigidity and easy breakage of solar cells, and achieve the effects of being convenient to carry and install, broadening the application field, and not easily broken and damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0064] S1, the laminator consists of a lower base 8 and an upper machine cover 6 to form a lamination chamber; an air bag 7 is horizontally arranged in the lamination chamber, and the air bag 7 divides the lamination chamber into an upper lamination chamber 9 and a lower lamination chamber 10;

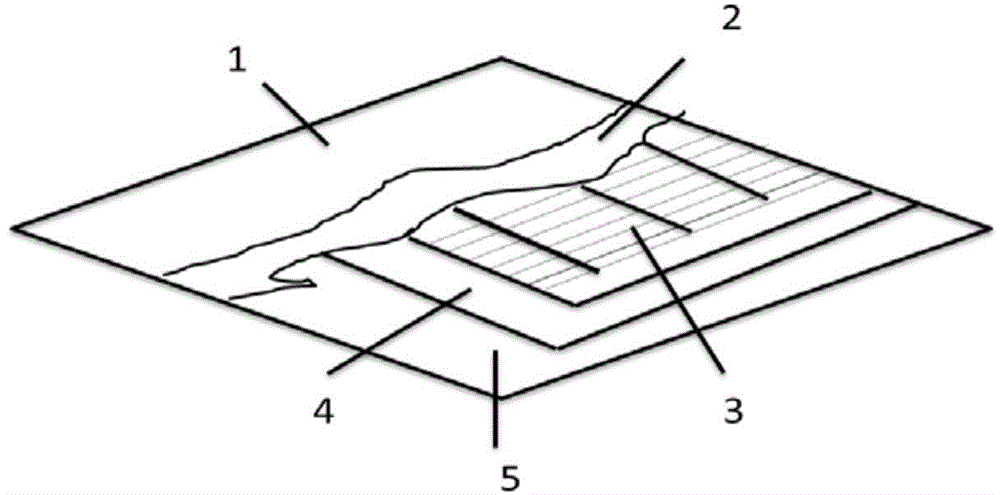

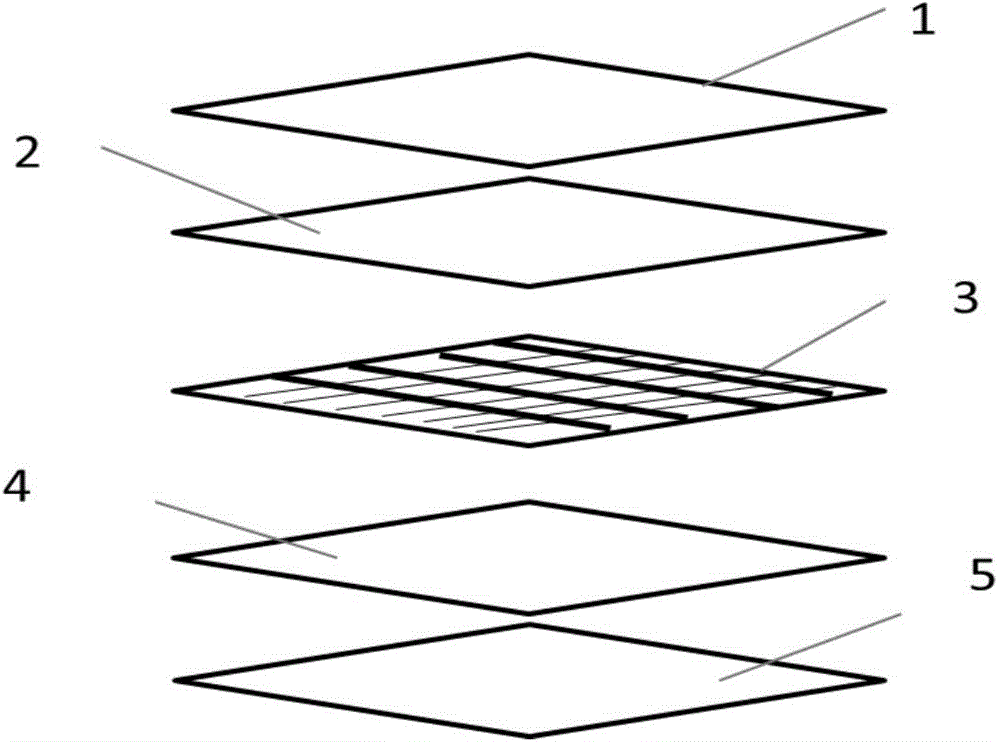

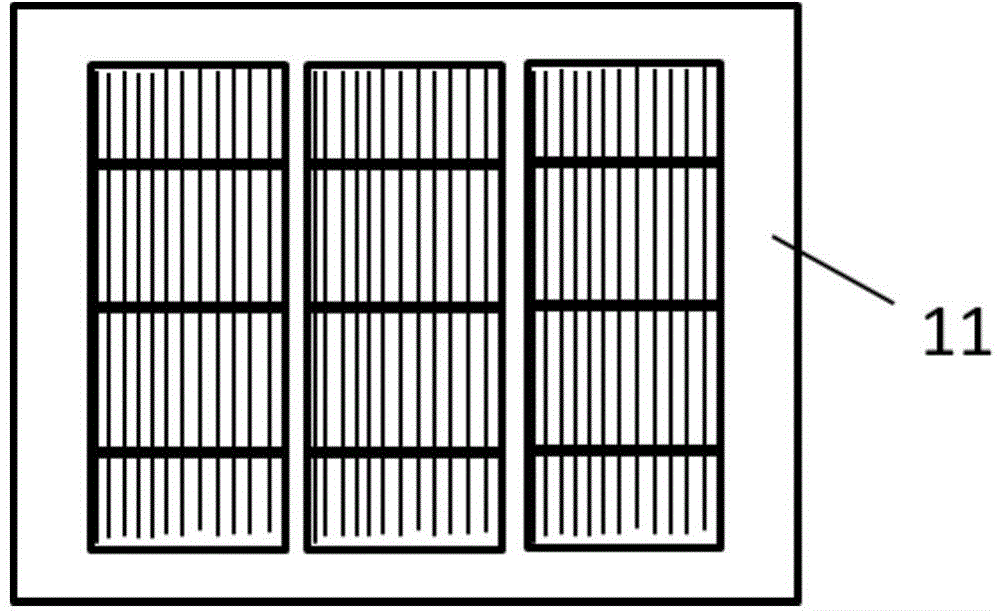

[0065] On the lower base 8 of the laminator, the back sheet 5, the first hot melt adhesive PVB, the solar cell sheet 3, the second hot melt adhesive PVB and the transparent waterproof vapor barrier are laid in sequence from bottom to top. Molecular Thin Film 1;

[0066] S2, closing the upper machine cover 6, at this time, the upper lamination chamber 9 and the lower lamination chamber 10 are both in an atmospheric pressure state;

[0067] The upper lamination chamber 9 and the lower lamination chamber 10 are evacuated to a vacuum state by vacuuming equipment; The temperature value T is 135°C;

[0068] S3, use the inflator to inflate the upper lamination chamber 9 with the first infl...

Embodiment 3

[0073] S1, the laminator consists of a lower base 8 and an upper machine cover 6 to form a lamination chamber; an air bag 7 is horizontally arranged in the lamination chamber, and the air bag 7 divides the lamination chamber into an upper lamination chamber 9 and a lower lamination chamber 10;

[0074] On the lower substrate 8 of the laminator, the back sheet 5, the first hot melt adhesive TPU, the solar cell sheet 3, the second hot melt adhesive TPU and the high transparent waterproof vapor are laid sequentially from bottom to top. Molecular Thin Film 1;

[0075] S2, closing the upper machine cover 6, at this time, the upper lamination chamber 9 and the lower lamination chamber 10 are both in an atmospheric pressure state;

[0076] The upper lamination chamber 9 and the lower lamination chamber 10 are evacuated to a vacuum state by vacuuming equipment; The temperature value T is 151°C;

[0077] S3, use the inflation device to inflate the upper lamination chamber 9 with the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com