Modularly-design multi-functional heating table mechanism

A modular design, multi-functional technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem of not clearly and completely expressing the general process and ideas of modular design, having little reference value, and not considering modular design. problems such as connecting elements, to achieve the effects of facilitating standardized management, improving machining accuracy, and strong interactivity and interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

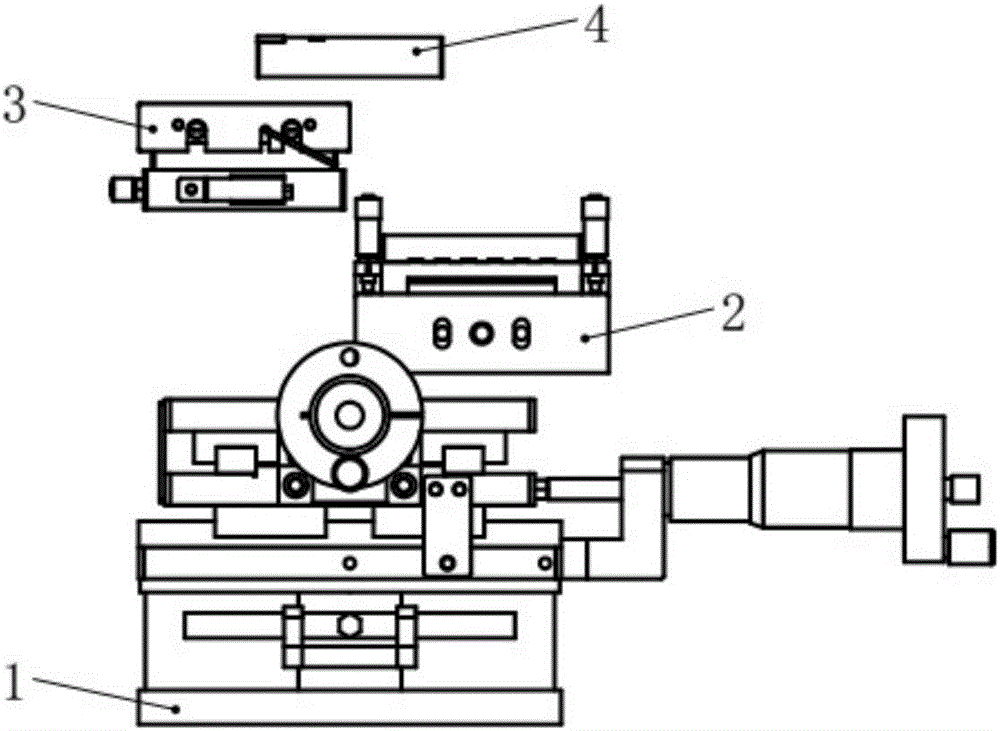

[0044] A multi-functional hot stage mechanism with modular design, its structure is as follows figure 1 As shown, the hot stage mechanism is set up sequentially from bottom to top:

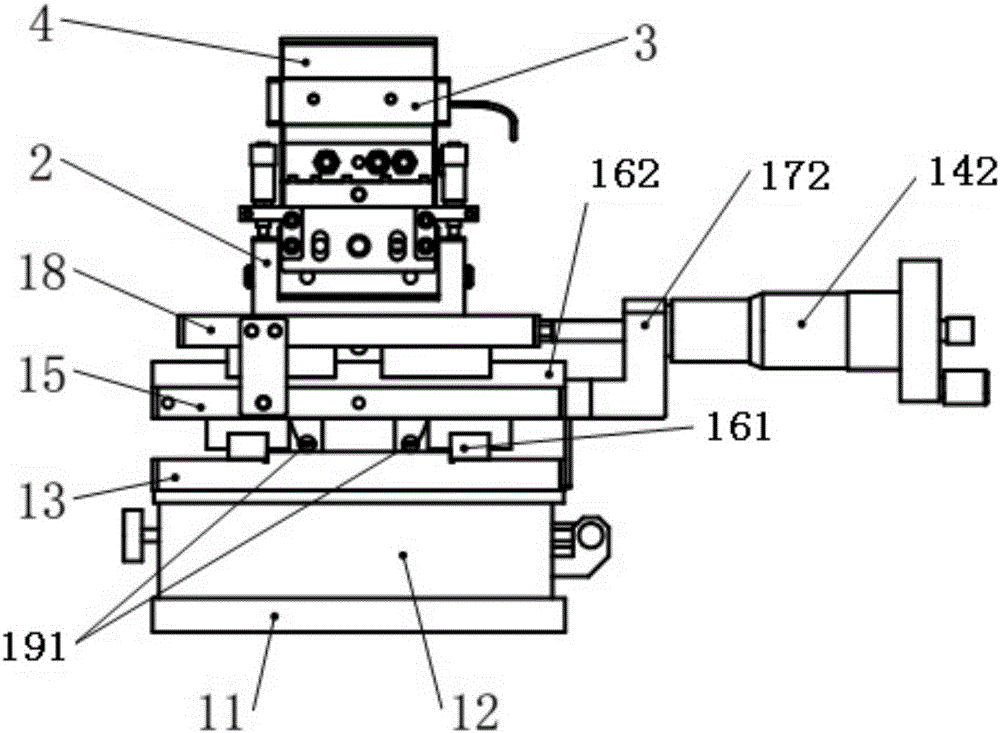

[0045] Motion abutment 1, its structure is as figure 2 and image 3 As shown: it includes a fixed bottom plate 11, a θ-axis sliding table 12 arranged on the fixed bottom plate 11 and rotating in the θ direction around the z-axis, and a first loading platform 13 arranged on the θ-axis sliding table 12 sequentially from bottom to top , the second carrying platform 15 moving along the y-axis and the third carrying platform 18 moving along the x-axis, the first carrying platform 13 is provided with a first guide rail 161 along the x-axis direction, and a first L-shaped connecting block 171, The first micrometer knob 141 is arranged on the first L-shaped connecting block 171, the second loading platform 15 is arranged on the first guide rail 161 and is connected with the first micrometer knob 141, a...

Embodiment 2

[0052] A multi-functional heating stage mechanism with modular design, the heating stage mechanism is set up sequentially from bottom to top:

[0053] Motion abutment 1, its structure is as figure 2 and image 3 As shown: it includes a fixed bottom plate 11, a θ-axis sliding table 12 arranged on the fixed bottom plate 11 and rotating in the θ direction around the z-axis, and a first loading platform 13 arranged on the θ-axis sliding table 12 sequentially from bottom to top , the second carrying platform 15 moving along the y-axis and the third carrying platform 18 moving along the x-axis, the first carrying platform 13 is provided with a first guide rail 161 along the x-axis direction, and a first L-shaped connecting block 171, The first micrometer knob 141 is arranged on the first L-shaped connecting block 171, the second loading platform 15 is arranged on the first guide rail 161 and is connected with the first micrometer knob 141, and the second loading platform 15 is pro...

Embodiment 3

[0057] A multi-functional heating stage mechanism with modular design, the heating stage mechanism is set up sequentially from bottom to top:

[0058] Motion abutment 1, its structure is as figure 2 and image 3 As shown: it includes a fixed bottom plate 11, a θ-axis sliding table 12 arranged on the fixed bottom plate 11 and rotating in the θ direction around the z-axis, and a first loading platform 13 arranged on the θ-axis sliding table 12 sequentially from bottom to top , the second carrying platform 15 moving along the y-axis and the third carrying platform 18 moving along the x-axis, the first carrying platform 13 is provided with a first guide rail 161 along the x-axis direction, and a first L-shaped connecting block 171, The first micrometer knob 141 is arranged on the first L-shaped connecting block 171, the second loading platform 15 is arranged on the first guide rail 161 and is connected with the first micrometer knob 141, and the second loading platform 15 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com