Method for realizing low temperature starting of equipment in circuit board

A circuit board and equipment technology, applied in the field of circuit board start-up, can solve problems such as difficulty in starting up electronic products, and achieve the effects of solving difficulty in starting up and failure to start up, simple design, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

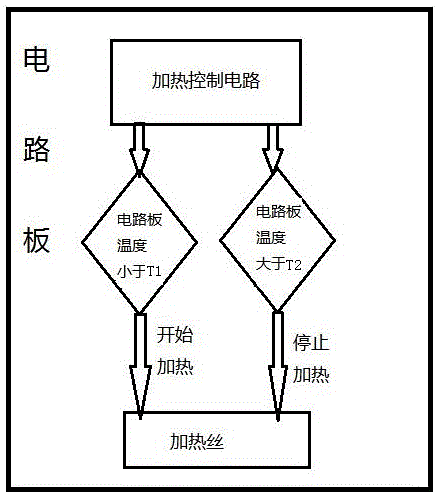

[0025] When the thermocouple detects that the temperature of the circuit board is lower than -30°C and does not meet the start-up conditions, the PID controller controls the heating wire to start working to increase the temperature of the corresponding position of the circuit board. When the thermocouple detects that the temperature of the circuit board is higher than 0°C, the PID controller controls the heating wire to stop working, and the circuit board can start normally at this time. When the galvanic couple detects that the temperature of the circuit board is lower than -30°C, the heating circuit is restarted, and the cycle repeats.

Embodiment 2

[0027] When the thermocouple detects that the temperature of the circuit board is lower than -40°C and does not meet the start-up conditions, the PID controller controls the heating wire to start working to increase the temperature of the corresponding position of the circuit board. When the thermocouple detects that the temperature of the circuit board is higher than -15°C, the PID controller controls the heating wire to stop working, and the circuit board can start normally at this time. When the galvanic couple detects that the temperature of the circuit board is lower than -40°C, the heating circuit is restarted, and the cycle repeats.

Embodiment 3

[0029] When the thermocouple detects that the temperature of the circuit board is lower than -50°C and does not meet the start-up conditions, the PID controller controls the heating wire to start working to increase the temperature of the corresponding position of the circuit board. When the thermocouple detects that the temperature of the circuit board is higher than -25°C, the PID controller controls the heating wire to stop working, and the circuit board can start normally at this time. When the galvanic couple detects that the temperature of the circuit board is lower than -50°C, the heating circuit is restarted, and the cycle repeats.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com