X-ray multi-purpose nondestructive flaw detection device and workpiece detection method thereof

A non-destructive testing and multi-functional technology, applied in the direction of using radiation for material analysis, etc., can solve the problems of insufficient detection accuracy, increased burden, increased construction costs, etc., to reduce the possibility of radiation damage, facilitate free entry and exit, and facilitate maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

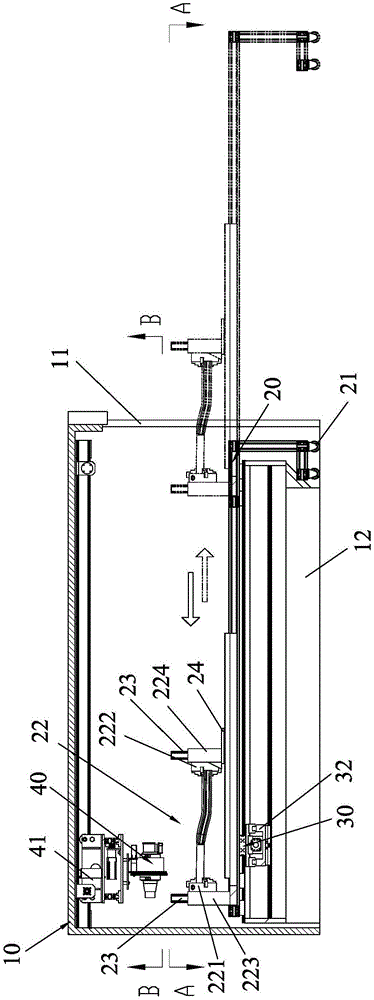

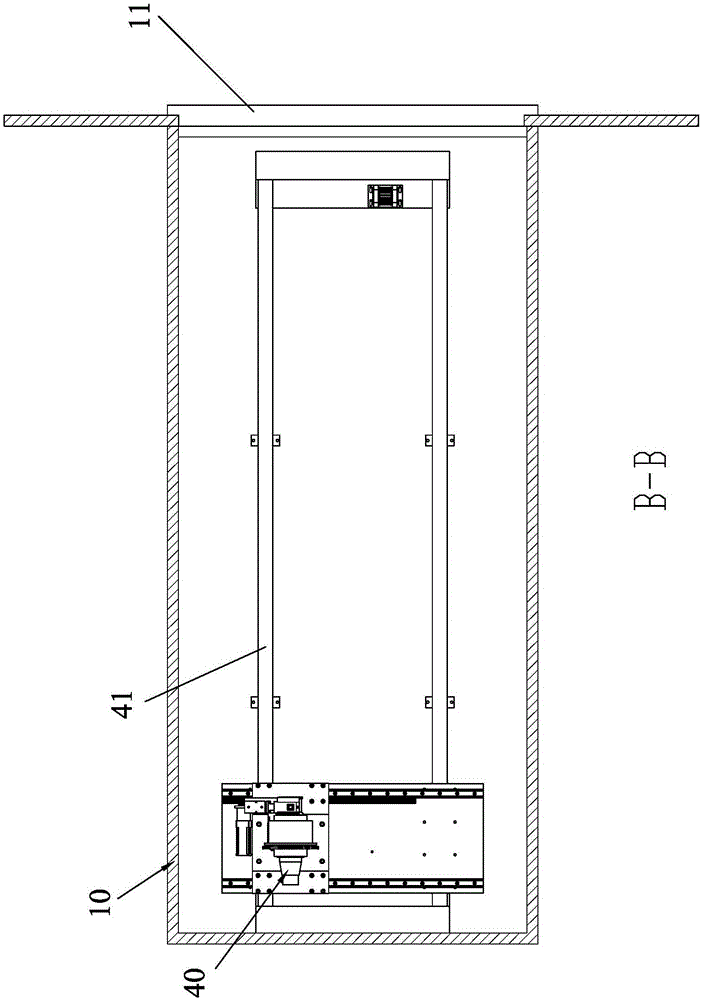

[0050] Please refer to Figure 1 to Figure 4 As shown, it shows the specific structure of the preferred embodiment of the present invention, which is an X-ray multifunctional nondestructive testing equipment, which is compatible with CT (stereoscopic) detection and DR (plane) detection functions , especially suitable for the detection of multi-variety, large-volume, small and complex structural parts. Its structure includes a protective lead room 10 , an object stage 20 arranged in the protective lead room 10 , a linear array detector 30 , and an X-ray machine 40 .

[0051]Wherein, the protective lead room 10 is equipped with an openable / closeable protective lead door 11 , and a sealed detection space is formed surrounded by the protective lead room 10 and the protective lead door 11 . In this embodiment, the protective lead door 11 of the protective lead room 10 has an up and down opening and closing structure. By configuring the independent protective lead room 10 accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com