Water-based heat-fluid-solid coupling true triaxial shear seepage test apparatus for coal body and test method using apparatus

An experimental device, true triaxial technology, applied in the field of thermal-fluid-solid coupled coal body true triaxial shear seepage experimental device, can solve problems such as misalignment, shear distortion, and inability to study coal bodies, so as to achieve realistic and accurate experimental results. The effect of flexible and convenient adjustment and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] The present invention will be described in detail below in conjunction with the accompanying drawings.

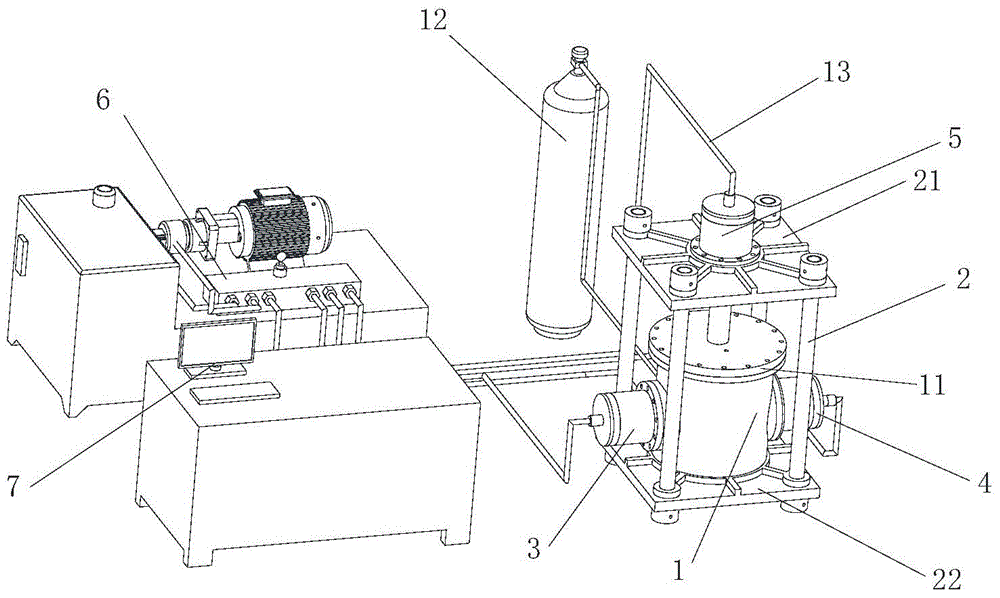

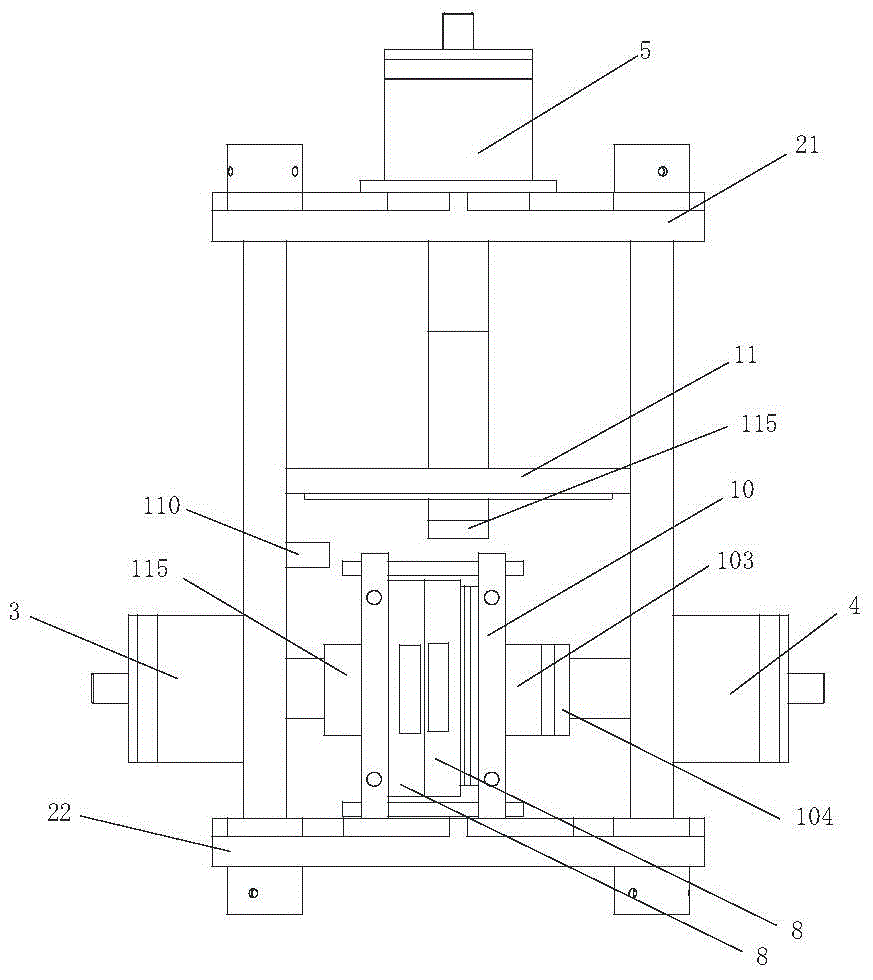

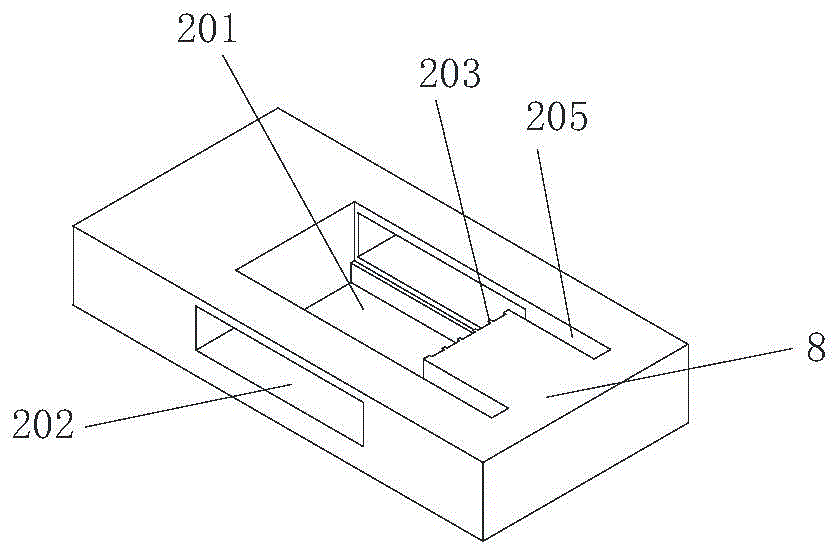

[0092] Such as figure 1 , figure 2As shown, the water-based heat-fluid-solid coupling coal body true triaxial shear seepage experimental device of the present invention is used with a hydraulic station 6 and a detection system 7, which includes a frame 2, a first hydraulic cylinder 5, and a second hydraulic cylinder 3. The third hydraulic cylinder 4. True triaxial pressure chamber 1. Specimen holding device; among them:

[0093] The above-mentioned frame 2 is a frame structure, including a top plate 21, a bottom plate 22 and a column;

[0094] The above-mentioned top plate and bottom plate are both rectangular steel plates, and the four corners of the above-mentioned rectangular steel plates are respectively provided with through holes;

[0095] There are four above-mentioned columns, and each column respectively passes through the corresponding through holes on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com