Water sampling robot in sewage treatment plant

A technology of sewage treatment plants and robots, applied in the direction of sampling devices, etc., can solve the problems of water quality decline, inability to detect water quality, illegal sewage discharge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

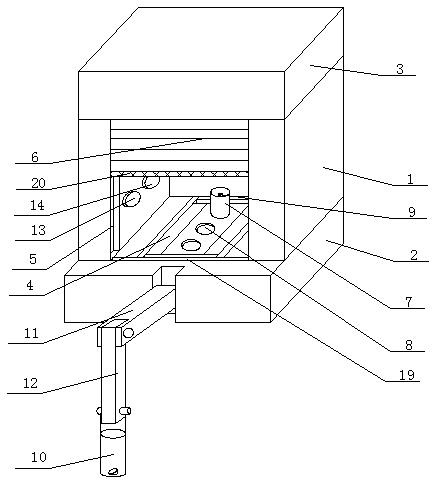

[0018] Below in conjunction with accompanying drawing, the present invention will be further described.

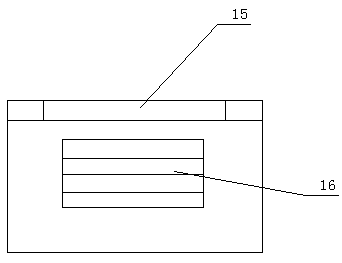

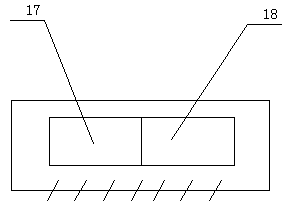

[0019] see Figure 1-Figure 3 As shown, the technical solution adopted in this specific embodiment is: it includes a body 1, an electric control room 2, a temperature / humidity adjustment room 3, a conveyor belt 4, a track 5, a rolling door 6, a water storage bucket 7, a placement tank 8, and a top column 9. Water fetching bucket 10, master arm 11, slave arm 12, humidity sensor 13, temperature sensor 14, rolling door installation area 15, blinds 16, temperature regulator 17, humidity regulator 18; the upper end of body 1 is provided with temperature / humidity adjustment chamber 3, the lower end of the body 1 is provided with an electric control room 2, the inner bottom side of the body 1 is provided with a conveyor belt 4, and several placement grooves 8 are arranged on the conveyor belt 4, and a water storage bucket 7 is arranged in the placement groove 8, The water stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com