Robot tool coordinate system correction method

A technology of tool coordinate system and calibration method, applied in the field of calibration of industrial robot tool coordinate system, can solve the problems of error, large error, time-consuming and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In practical applications, robots complete various operations by installing actuators (such as processing tools or clamping fixtures) at their ends. In this embodiment, the robot grabs the workpiece through the actuator for processing. Before processing, it is usually necessary to define a tool coordinate system on the workpiece grabbed by the actuator. The accuracy of the tool coordinate system directly affects the precise operation of the robot. In this embodiment, the coordinate system where the workpiece is located is the actual tool coordinate system, and the robot defines a basic tool coordinate system to obtain the actual tool coordinate system of the workpiece grasped by the robot. The correction of the tool coordinate system of the workpiece on the robot by using the robot tool coordinate system correction method of the present invention will be described in detail below.

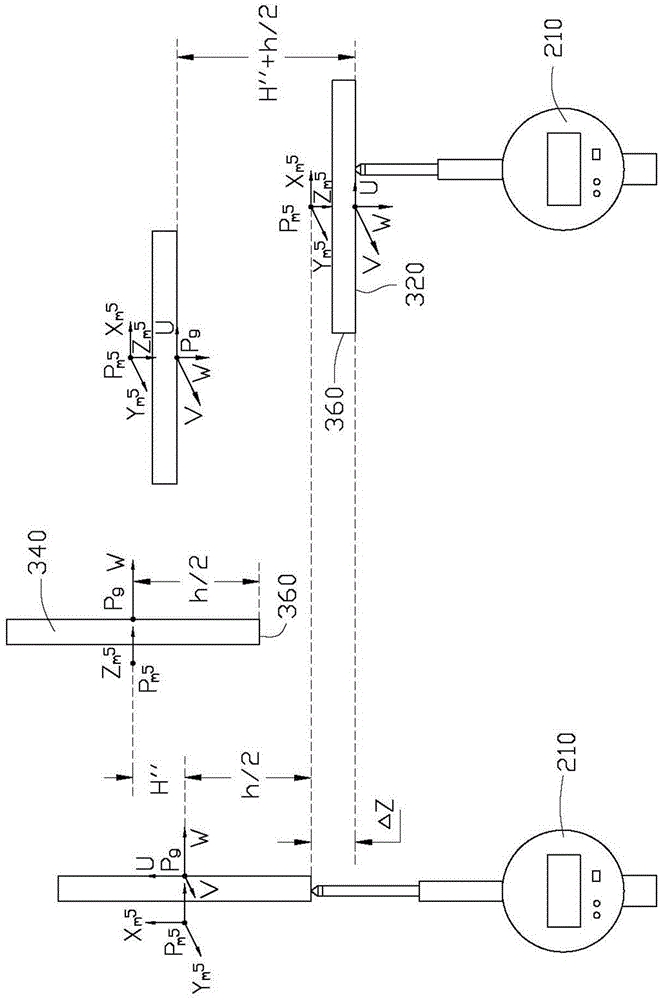

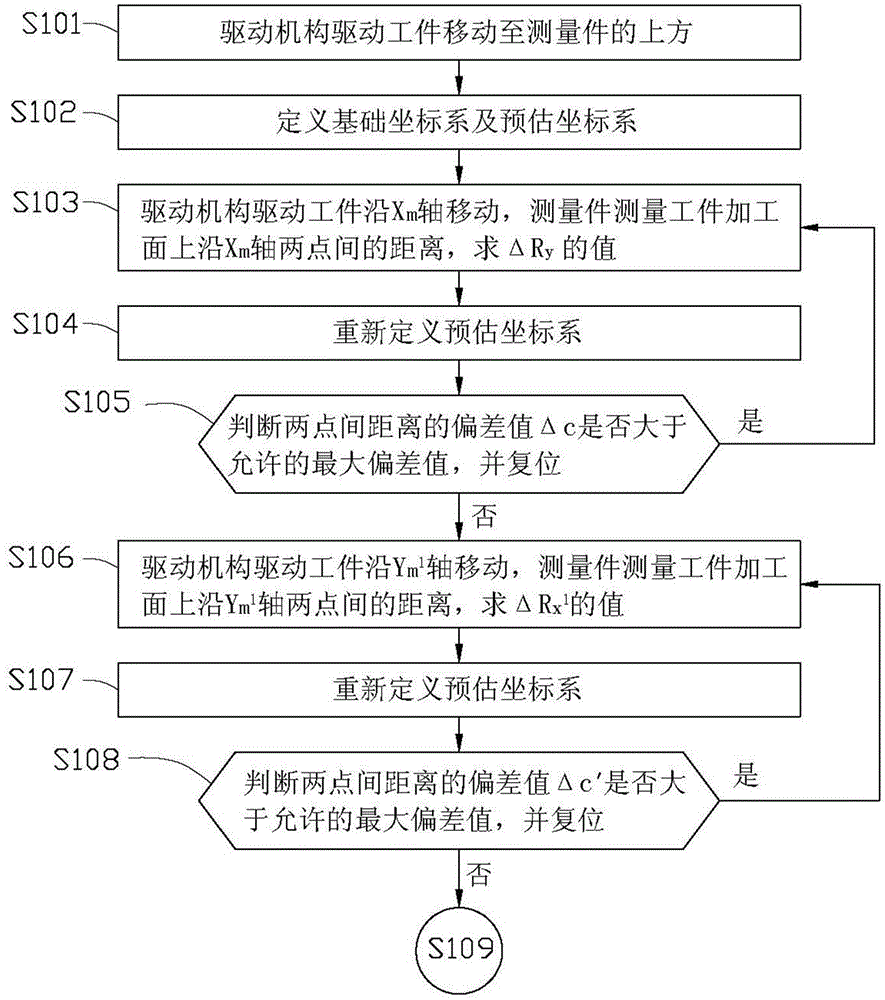

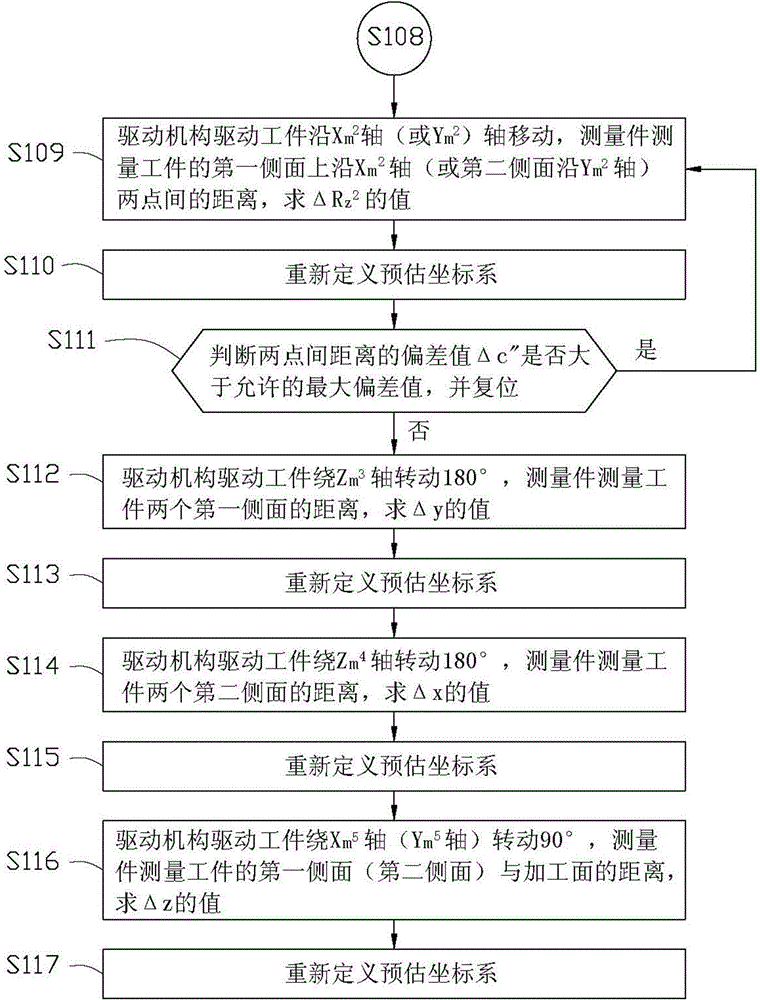

[0016] see Figure 1 to Figure 3 In the robot tool coordinate system calibration method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com