Automatic feeding mechanism

A technology of automatic feeding and feeding mechanism, which is applied in the microwave field, can solve the problems of high cost, uneven spatial distribution, and many operating equipment, so as to reduce the space for equipment operation, high degree of equipment automation, and small equipment operation space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

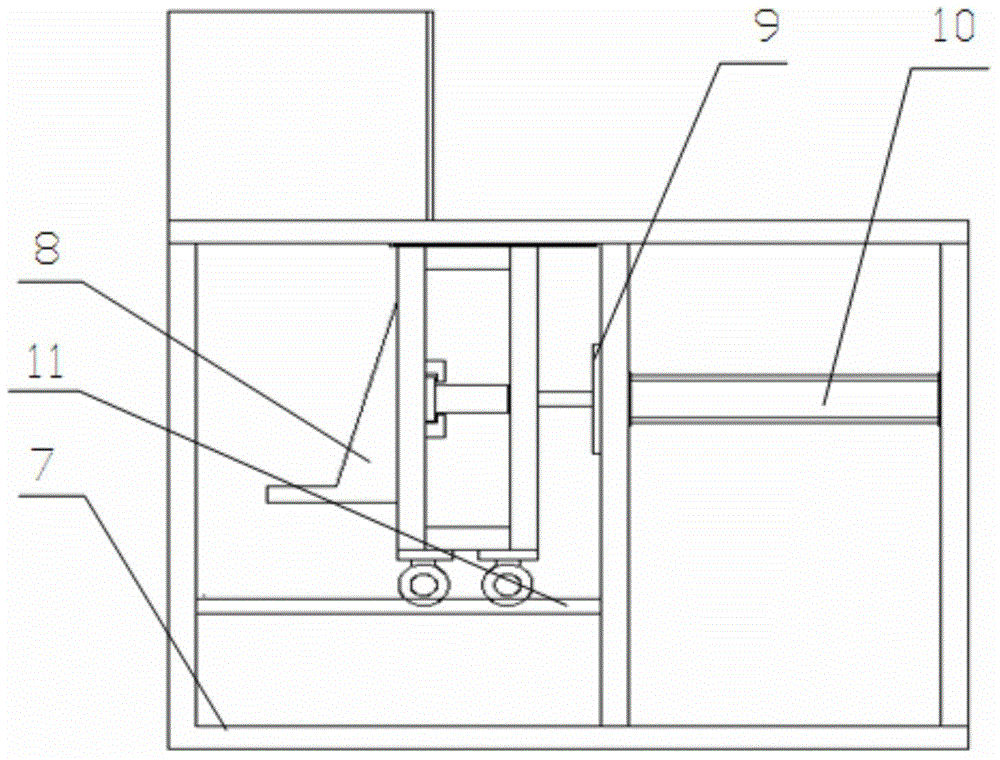

[0014] The automatic feeding mechanism of the present invention is mainly composed of two parts: a belt line feeding mechanism and a cylinder feeding mechanism.

[0015] Belt line feeding mechanism

[0016] Such as figure 1 As shown, the belt line feeding mechanism includes a conveyor belt 3, a movable machine leg 2, a first group of guide rails 1, a first cylinder 4 and a second group of guide rails 5;

[0017] The conveyor belt 3 is equipped with at least two rollers on both sides near the upper end of the bin door 6, the rollers are placed on the second group of guide rails 5, and the second group of guide rails 5 are arranged on the table top of the cylinder feeding mechanism frame 7, The other end of the conveyor belt 3 is fixedly placed on the mobile machine leg 2; at least two rollers are installed at the lower end of the mobile machine leg 2, and the mobile machine leg 2 is placed on the first group of guide rails 1 by the rollers on the machine leg.

[0018] The mob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com