Tray-piston type swing executor driven tray-piston type swing pressure-feeding fluid machine

A swing actuator, piston technology, applied in swing piston machinery, machine/engine, swing piston pump, etc., can solve the problem of low corrosion resistance of metal materials, complex structure, and the difficulty of pumping fluid by centrifugal pump to meet high pressure. requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

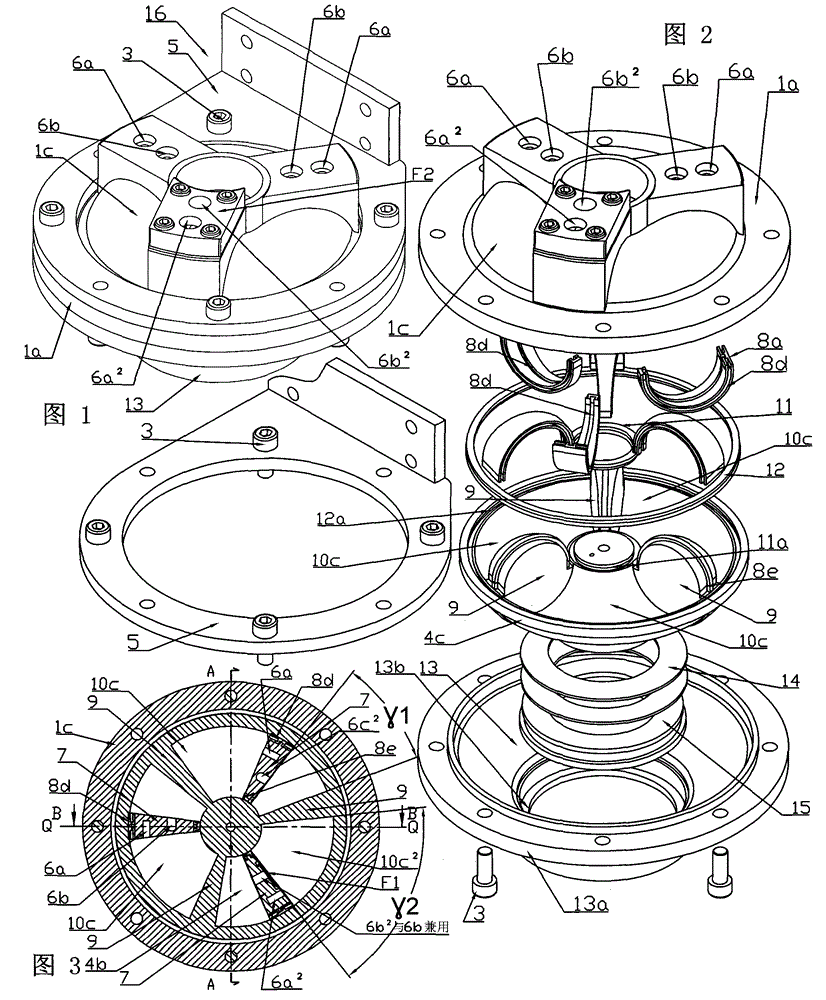

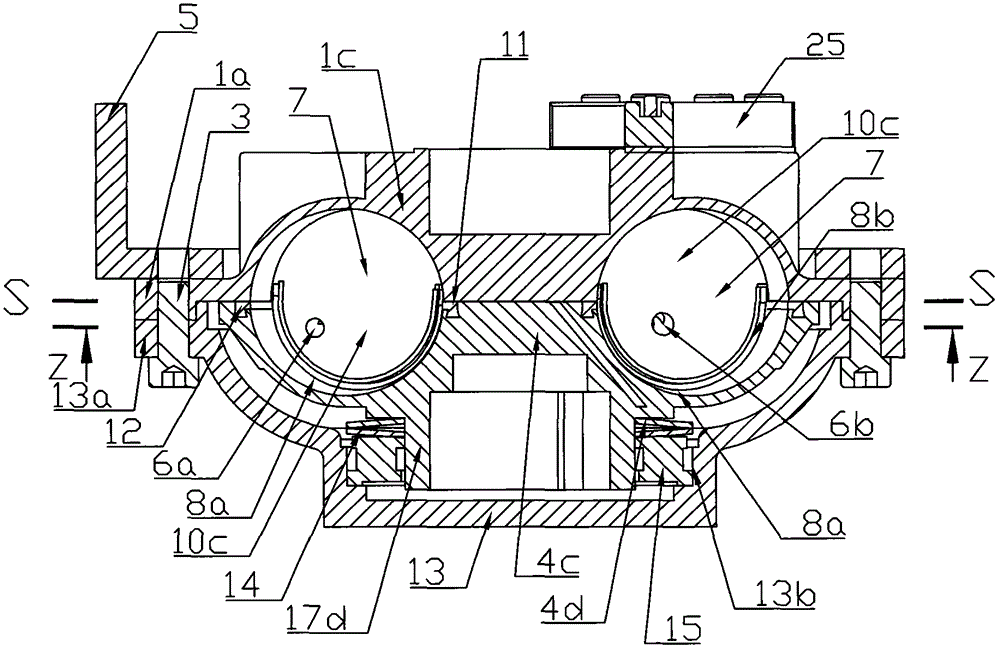

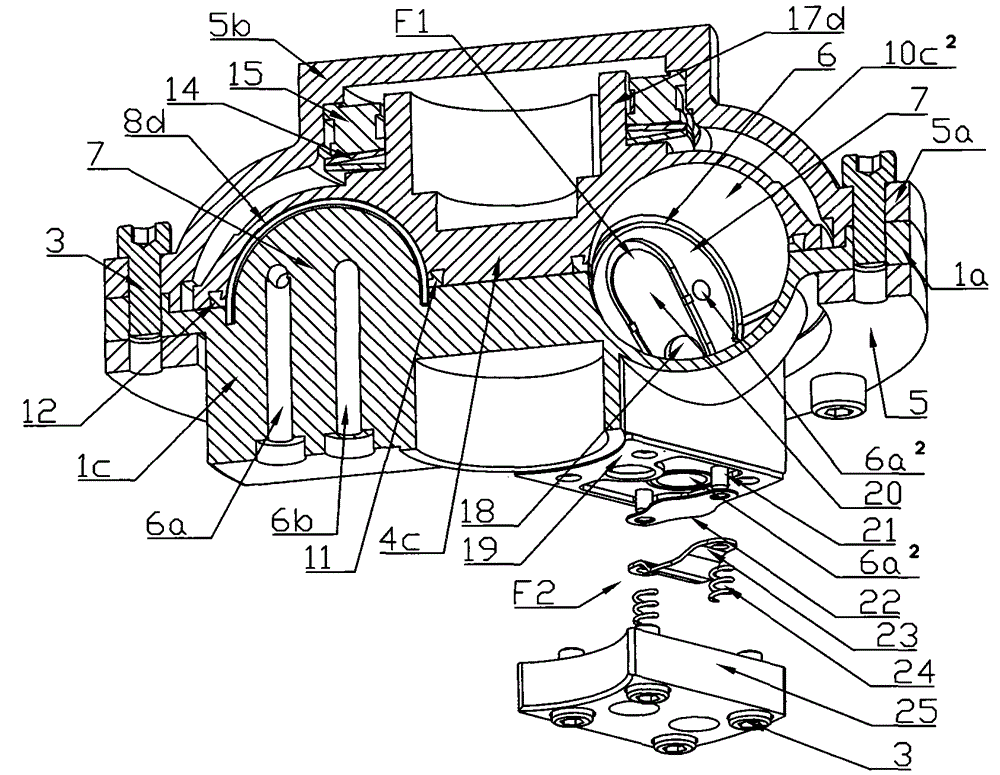

[0041] The pallet piston rocking pressure-feeding fluid machine driven by the pallet piston rocking actuator of the present invention will be further described below in conjunction with the accompanying drawings.

[0042] exist Figures 1 to 5 , shows the general embodiment 1 of the pallet piston rocking hydraulic fluid machine driven by the pallet piston rocking actuator. This embodiment is the first example of the pallet-piston type rocking pressure-feeding gas machine 16, which is especially suitable for pumping liquid.

[0043] refer to Figures 1 to 6 , a pallet piston type rocking pressure-feeding fluid machine driven by a pallet piston rocking actuator, comprising a bracket 5, a pallet piston rocking actuator in the pallet piston rocking actuator, a pallet piston rocking pressure-feeding fluid head, a cooling System and driving force generation system; the cooling system is a mechanism for naturally cooling the components of the pressure-feeding fluid machine; the pal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com