A self-centering rotary cutting tool

A technology of rotary cutting and tools, applied in wellbore/well parts, earthwork drilling and production, etc., can solve problems such as unusable tubing, outer layer oil, casing damage, small inner diameter of tubing string, etc., and reduce the risk of off-cutting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

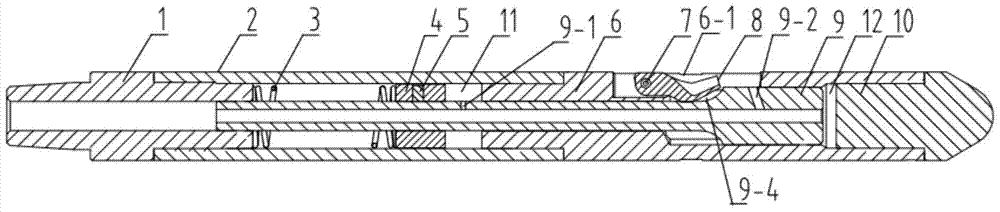

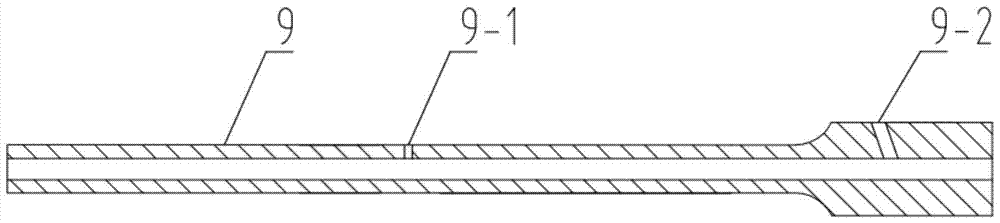

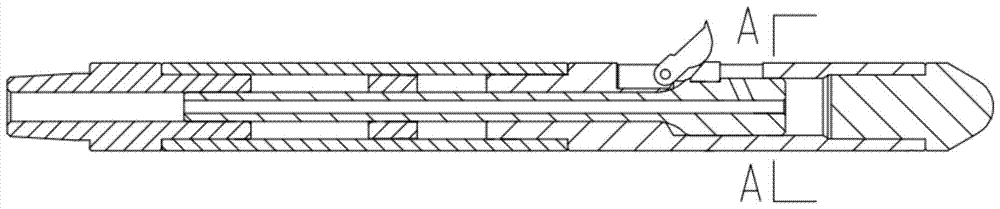

[0024] like Figure 1 to Figure 4 As shown, a self-centering rotary cutting tool includes an upper joint 1, a first shell 2, and a second shell 6, all of which are hollow structures, and the upper joint 1 and the second shell 6 are respectively connected to the first The right end and the left end of a housing 2 form a combined cavity, the right end of the second housing 6 is provided with a plug 10, and the outer wall of the second housing 6 is symmetrically provided with three handle grooves 6-1, Each said handle groove is provided with a retractable handle 8; it also includes a mandrel 9 in a hollow structure, said mandrel 9 can be slidably inserted into said combination cavity, and said mandrel 9 The fixing sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com