Steel strand cable with polyurea protective material on outer layer and manufacturing method thereof

A technology of protective materials and production methods, which can be applied to rope-making auxiliary devices, textile cables, construction, etc., can solve the problems of easy pinholes, poor wear resistance, and easy wear and tear of coatings, etc., so as to prolong the service life and excellent Abrasion resistance, coating continuous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] A steel strand cable with a polyurea protective material on the outermost layer of the steel strand assembly coated with a layer of polyurea protective coating I:

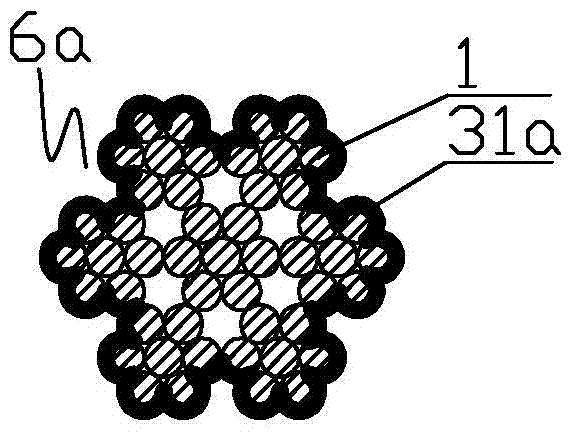

[0087] Such as Picture 1-1 , the steel strand cable with polyurea protective material on the outer layer includes a steel strand assembly composed of 7 steel strands, and a polyurea protective coating is coated on the outermost layer of the 7 steel strand assemblies I31a, constituting the steel strand cable Ia with polyurea protective material on the outer layer of the present invention.

[0088] The single steel strand is twisted by 1 central wire and 6 side wires, including a smooth steel strand made of smooth steel wire or an epoxy coating attached to the outer periphery of the smooth steel wire , galvanized coating, plastic coating, anti-corrosion grease coating, oily wax or metal coating, anti-corrosion steel strands composed of anti-corrosion steel wires with coatings or coatings on the surface, here...

Embodiment 2

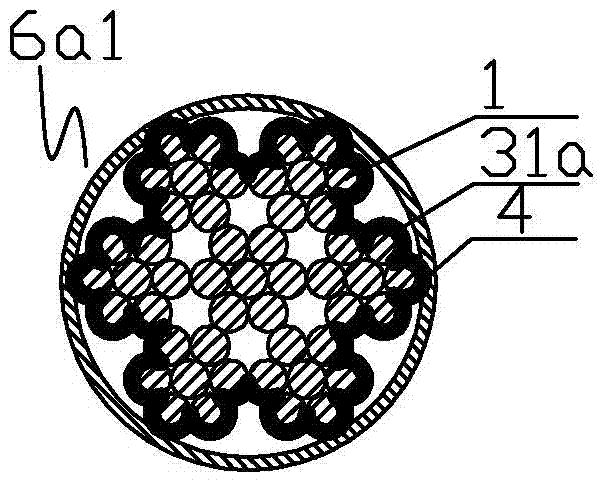

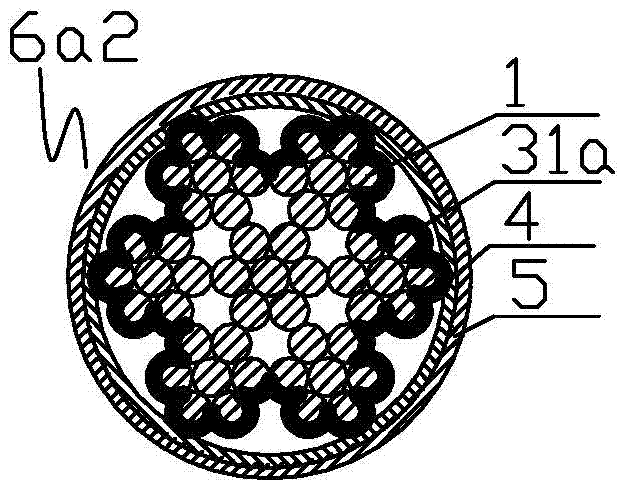

[0094] The outer layer of the steel strand cable Ia with polyurea protective material on the outer layer is coated with a layer of polyurea protective coating II, which has multiple protective layers. The steel strand cable with polyurea protective material on the outer layer Search:

[0095] Such as diagram 2-1 As shown, there is also a wrapping tape 2 wrapped around the outer circumference of the steel strand cable Ia of the steel strand cable Ia of the polyurea protective material in the outer layer described in embodiment one, forming a steel wire with a polyurea protective material in the outer layer. Stranded cable Ia0 (see diagram 2-1 ); then the outer layer of the wrapping tape 2 of the steel strand cable Ia0 with polyurea protective material is coated with a layer of polyurea protective coating II31b, forming the steel strand cable Ia0b with the outer layer of polyurea protective material (see Figure 2-2 );

[0096] As a transformation of the embodiment of the ...

Embodiment 3

[0101] A manufacturing method of a steel strand cable with a polyurea protective material on its outer layer as described in Embodiment 1, the steel strand cable with a polyurea protective material on its outer layer includes a steel strand combination composed of n steel strands body, the single steel strand is either a smooth steel strand made of smooth steel wire or a steel strand with epoxy coating, galvanized coating, plastic coating, anti-corrosion grease attached to the outer periphery of the smooth steel wire Anti-corrosion steel strands composed of anti-corrosion steel wires with coatings, oily wax or metal coatings attached to the surface of coatings or coatings, hereinafter collectively referred to as steel strands, the production method of steel strand cables with polyurea protective materials on the outer layer Basic steps include:

[0102] A. Pretreatment: Perform the following pretreatment on the steel strand:

[0103] A1: Strictly inspect the raw steel strands...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com