Industrial splicing and sewing machine easy to operate

A patchwork sewing machine and industrial technology, applied to sewing machine components, sewing machine control devices, cloth feeding mechanisms, etc., can solve problems such as difficult alignment of upper and lower garment parts, inaccurate patchwork control, low production efficiency, etc., to improve product quality Grade, speed equalization, and quality-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with specific embodiment, further illustrate the present invention.

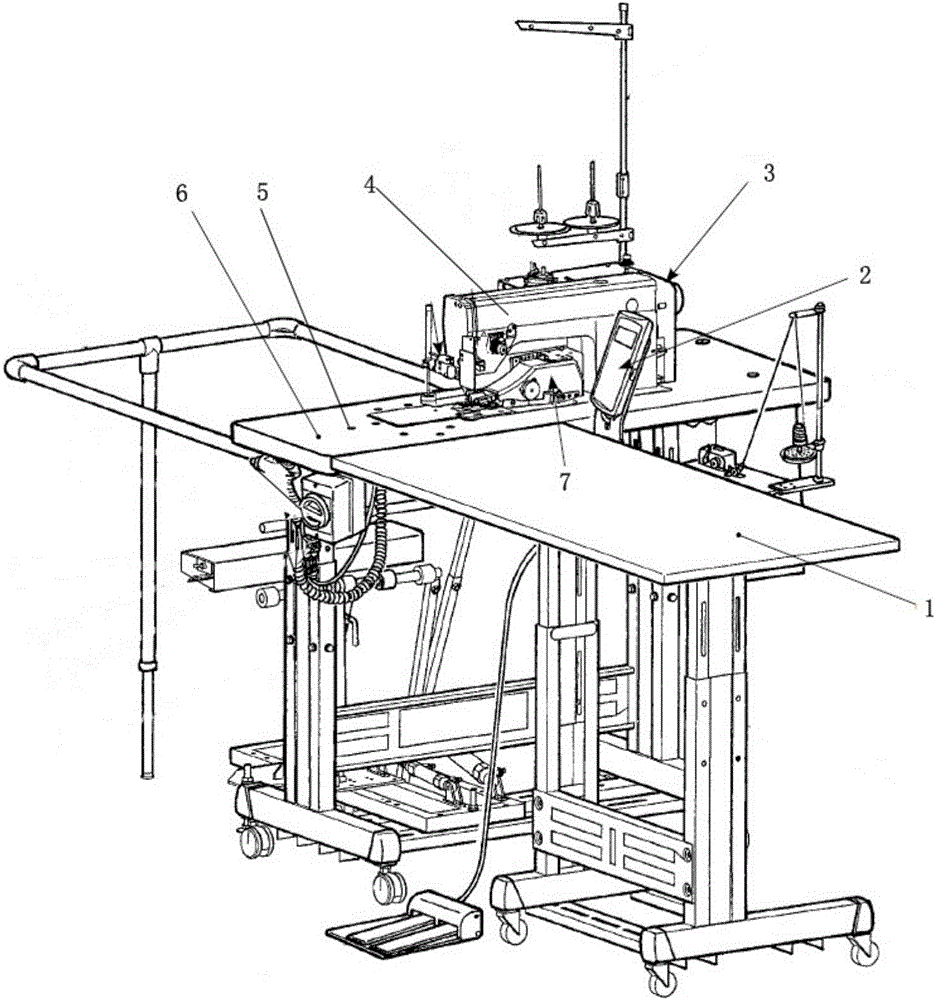

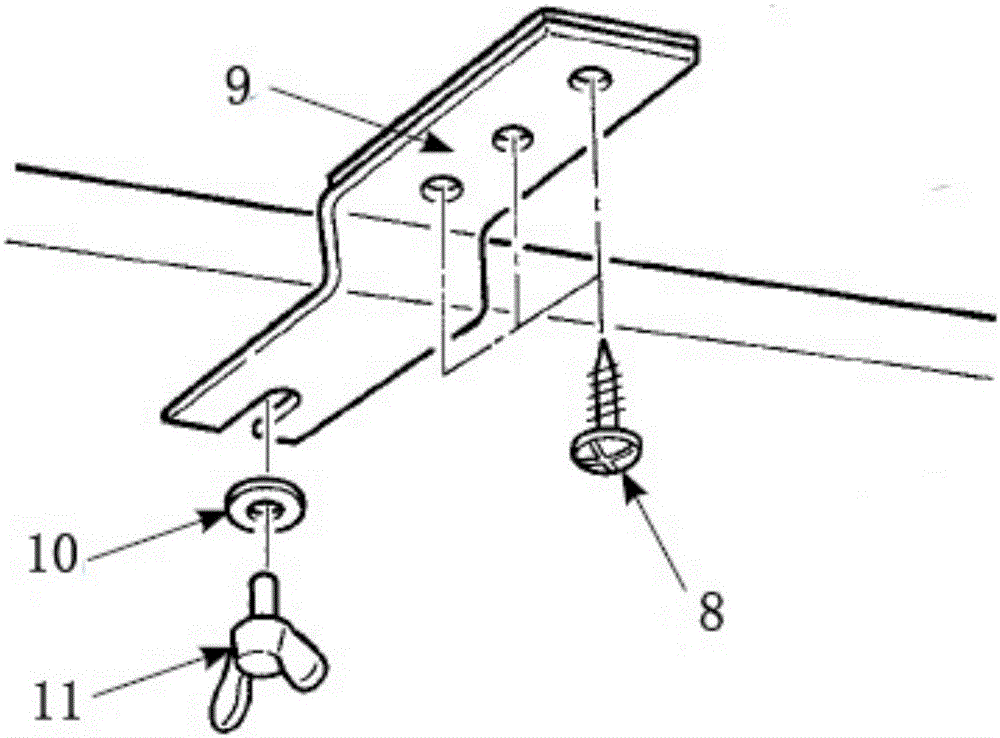

[0020] Such as Figure 1-4 As shown, an easy-to-operate industrial patchwork sewing machine includes a main table of the sewing machine and a sewing main machine. The head of the sewing main machine 4 is connected by a direct drive servo motor 3, and an electric control system is arranged on the side of the main table 6. The electric control system includes a liquid crystal The display surface and the control interface are embedded on a rotatable bracket. The electric control system 2 controls the start-up and rotating speed of the sewing machine, the feeding speed of the main table and the auxiliary table 1, the lifting height, the pressure and the extension position of the upper and lower manipulators, etc.

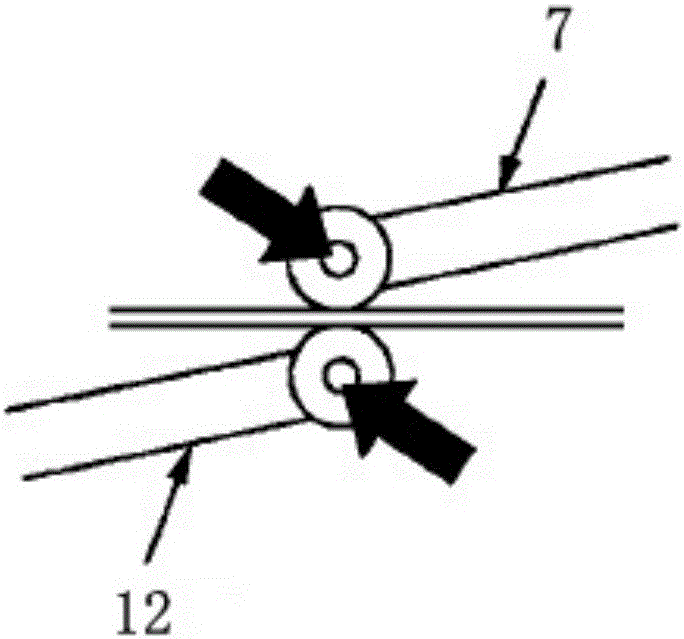

[0021] It also includes multiple groups of photoelectric devices capable of monitoring the position of the fabric to be stitched and the regularity of the outer edge of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com