Stretchable flexible super-lyophobic film and its preparation method and droplet non-destructive transfer method

A super-lyophobic and thin-film technology, applied in coatings, nanotechnology, etc., can solve problems such as inconvenient system integration, and achieve the effect of broadening the application range and excellent wetting characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

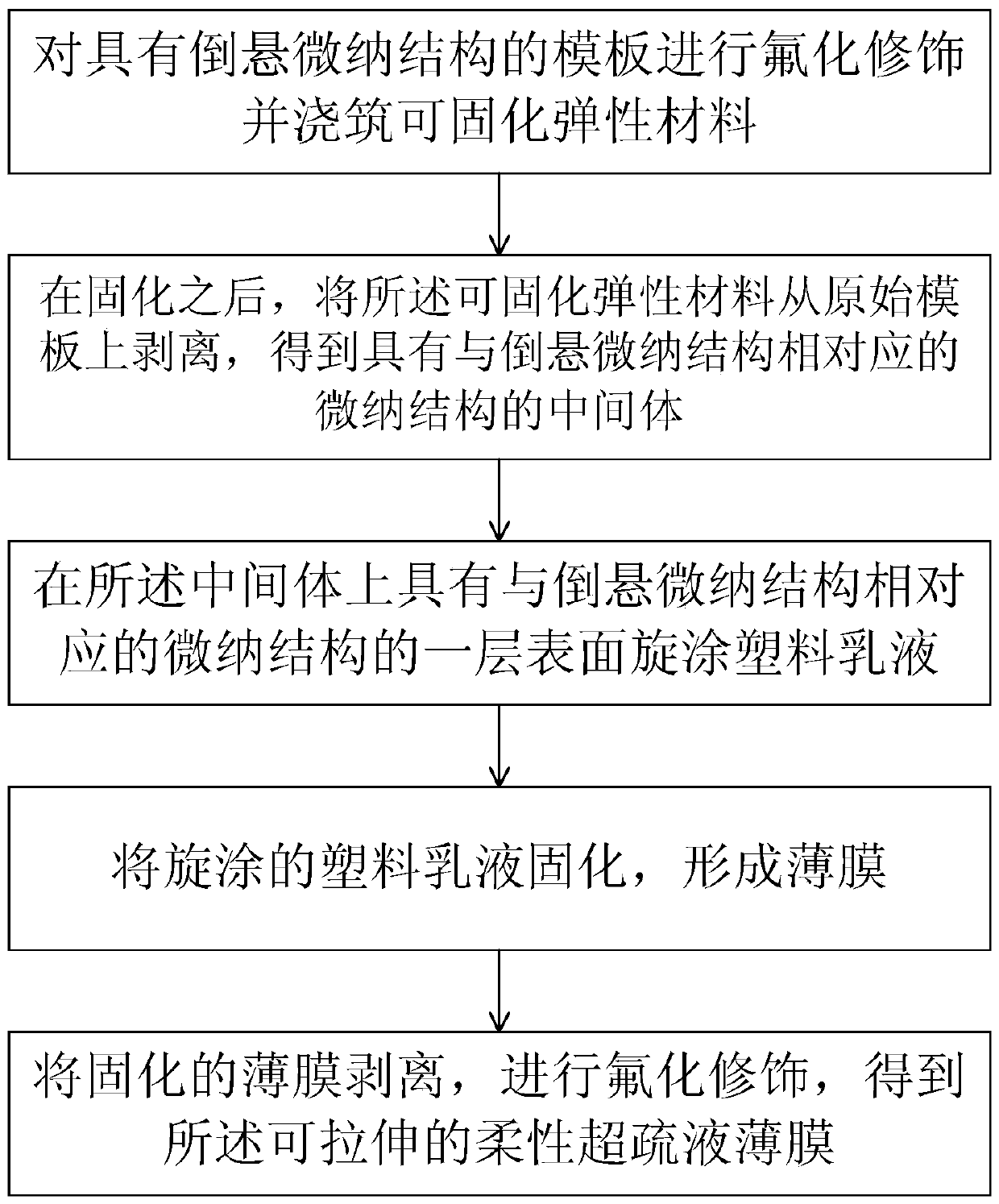

[0040] The present embodiment provides a kind of preparation method of stretchable flexible super-lyophobic film, it comprises the following steps:

[0041] (1) After cleaning and drying the original template with T-shaped micro-nano structure, place it on a hot stage, set the temperature of the hot stage to 150°C, place a clean glass slide next to the template, and preheat it for 3 minutes. Take out perfluorodecyltrichlorosilane (PFTS), drop two points on the glass slide on the hot stage with a disposable straw, buckle a glass vessel on the original template surface on the hot stage, and heat the hot stage for 4 minutes to obtain Best hydrophobic effect.

[0042] (2) Remove the inverted glassware, pour the pre-configured curable elastic material polydimethylsiloxane (PDMS) into the petri dish, put it into a vacuum drying oven at 80°C, vacuumize and dry Bake for 2 hours to cure the curable elastic material PDMS, and peel off the curable elastic material PDMS to obtain an inte...

Embodiment 2

[0047] This embodiment provides a method for non-destructive transfer of droplets, the process of which is as follows figure 2 As shown, the super-lyophobic surface prepared in Example 1 has the characteristics of good flexibility and good stretchability, and can perform droplet manipulation and non-destructive transfer. The method specifically includes the following steps:

[0048] First, the droplet 22 is placed on the superlyophobic film 23;

[0049] Secondly, the flexible transparent super-lyophobic film 21 prepared in operation example 1 grabs the droplets from the super-lyophobic film 23;

[0050] Finally, stretching the superlyophobic film 21 reduces the adhesion of the film to the droplet, allowing the droplet 22 to fall off the film for lossless transfer to any other surface.

Embodiment 3

[0052] This example provides another non-destructive droplet transfer method, which uses the characteristics of good flexibility and good stretchability of the super-lyophobic surface prepared in Example 1 to perform droplet manipulation and non-destructive transfer. The method specifically includes the following steps:

[0053] First, the droplet 22 is placed on the superlyophobic film 23;

[0054] Secondly, the flexible transparent super-lyophobic film 21 prepared in operation example 1 grabs the droplets from the super-lyophobic film 23;

[0055] Finally, by bending the super-lyophobic film 21 to change the local curvature of the contact between the film and the droplet, the adhesion force of the film to the droplet is reduced, so that the droplet 22 falls from the film and transfers to any other surface without damage.

[0056] image 3 It is a diagram of the control process for realizing the lossless transfer of droplets by actually manipulating droplets based on the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com