Waste residue utilization system of concrete mixing plant and operation technology

A mixing station and concrete technology, which is applied in the waste residue utilization system of concrete mixing station and its operation process, can solve the problems of environmental pollution, etc., and achieve the effect of short construction period, low cost and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

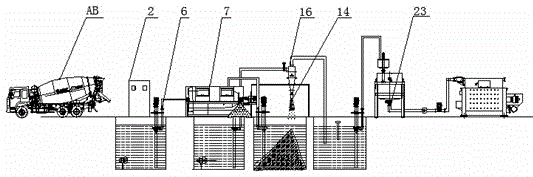

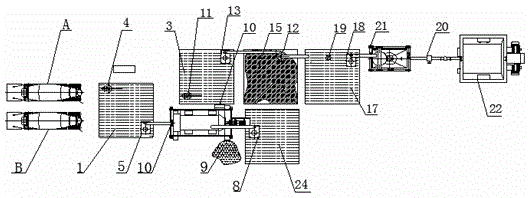

[0013] Such as figure 1 and figure 2 As shown, the present invention discloses a waste residue utilization system of a concrete mixing station, including a waste slurry pool 1, a submersible mixer a4 is installed in the waste slurry pool 1; the pumping pipe of the slurry pump a5 extends into the waste slurry pool In 1, a connecting pipe is installed at the slag outlet 6 of the slurry pump a5, and the other end of the connecting pipe is connected with the grading screen 7; one end of the grading sieve 7 is the sewage and sand outlet 10, and the other end is the gravel outlet 9; One end of the stone outlet 9 of the sieve 7 is connected with the clean water pump 8, and the clean water pump 8 is installed in the clean water tank 24; a grit chamber 3 is provided on one side of the grading screen 7; a submersible mixer b11 and a slurry pump are ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com