A kind of dry chili shearing and separating machine

A dry chili and separator technology, which is applied in the field of dry chili body pedicle shearing separator, can solve the problems of high labor intensity, great human stimulation, and low work efficiency, and achieve the goal of reducing labor intensity, reducing stimulation, and improving efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

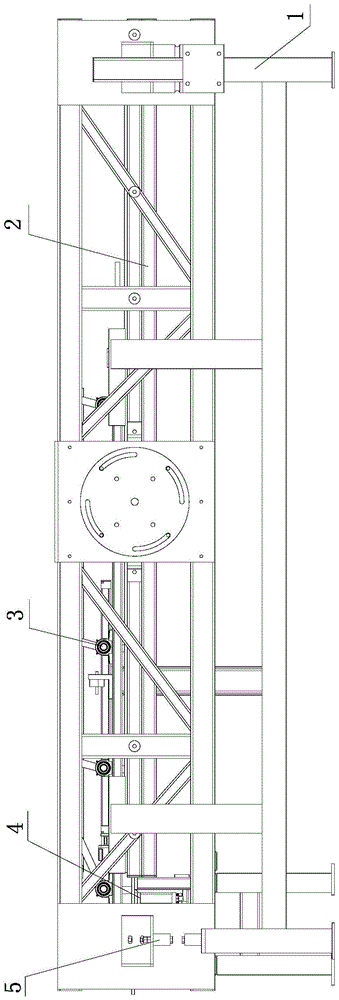

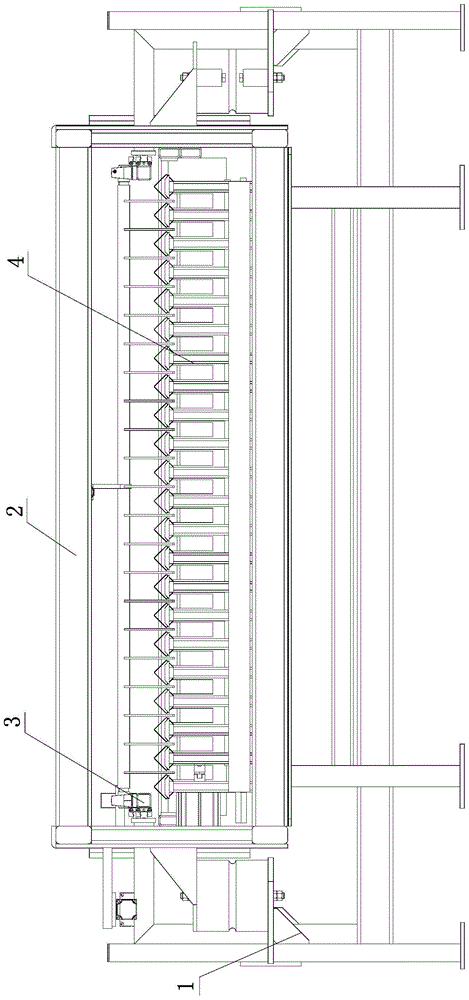

[0012] Specific implementation mode one: combine Figure 1-Figure 10 Illustrate, a kind of dried chili shearing separator of the present embodiment comprises body frame 1, linear vibrating screen 2, carder 3 and cutter device 4;

[0013] The cutter device 4 and the linear vibrating screen 2 are installed on the body frame 1, the cutter device 4 and the linear vibrating screen 2 are adjacently arranged, and the top of the linear vibrating screen 2 is equipped with a carder 3 for combing dried peppers;

[0014] The cutter device 4 includes a first cylinder 4-1, an upper cutter frame 4-2, a lower cutter frame 4-3, several upper blades 4-4 and several lower blades 4-5;

[0015] The upper cutter frame 4-2 is fixed on the body frame 1; the lower cutter frame 4-3 is arranged in the upper cutter frame 4-2, and the piston rod of the first cylinder 4-1 is connected with the lower cutter frame 4-3, The lower cutter frame 4-3 is slidably mounted on the upper cutter frame 4-2;

[0016] S...

specific Embodiment approach 2

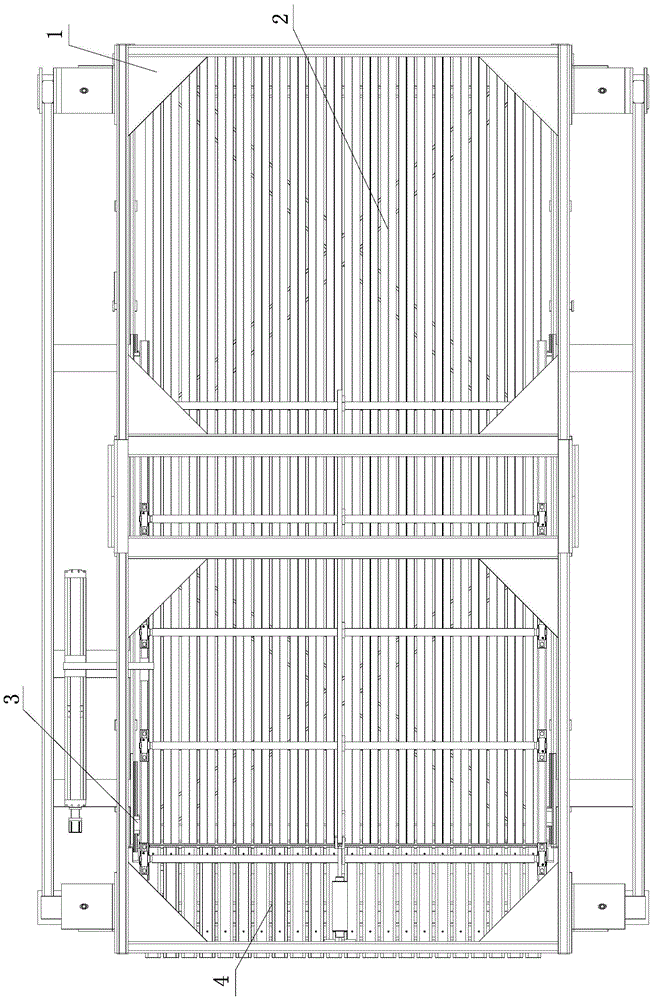

[0018] Specific implementation mode two: combination Figure 1-Figure 2 and Figure 4-Figure 5 Explain that the comber 3 of the present embodiment includes a second cylinder 3-1, a connecting rod 3-2, a fixed frame 3-3 and several driving rods 3-4;

[0019] The second cylinder 3-1 is fixed on the body frame 1, and the piston rod of the second cylinder 3-1 is connected with one end of the connecting rod 3-2, and the connecting rod 3-2 is fixedly equipped with a fixed mount 3-3, and the fixed mount 3-3 is slidably installed on the body frame 1, and the lower surface of the fixed frame 3-3 is fixed with a plurality of vertically arranged driving rods 3-4, and the free ends of the driving rods 3-4 are close to the screen surface of the vibrating screen 2 Set, the moving direction of fixed frame 3-3 is identical with the moving direction of dried chili. In this way, the connecting rod moves under the drive of the second cylinder, and then drives the fixed frame to reciprocate on ...

specific Embodiment approach 3

[0020] Specific implementation mode three: combination Figure 4 and Figure 6 Note that the fixed frame 3-3 in this embodiment includes two fixed rods 3-5, an even number of slide rails 3-6 and several support rods 3-7;

[0021] Two fixed rods 3-5 are arranged side by side, and an even number of sliders 3-6 are fixed on each fixed rod 3-5, and the sliders 3-6 are slidably installed on the body frame 1. A plurality of support rods 3-7 arranged side by side are arranged in between, and the lower end surface of each support rod 3-7 is fixedly equipped with several rod root driving rods 3-4 arranged vertically side by side. Such a design has a simple and reliable structure, which is beneficial to the shifting of the dried chili by the lever, dredging the sieve, and ensuring the smooth transportation and shearing of the dried chili. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com