Polishing device for inner wall of stainless steel pipe fitting

A stainless steel pipe and polishing device technology, which is applied in the direction of surface polishing machine tools, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of poor polishing and poor polishing effect of stainless steel pipe fittings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

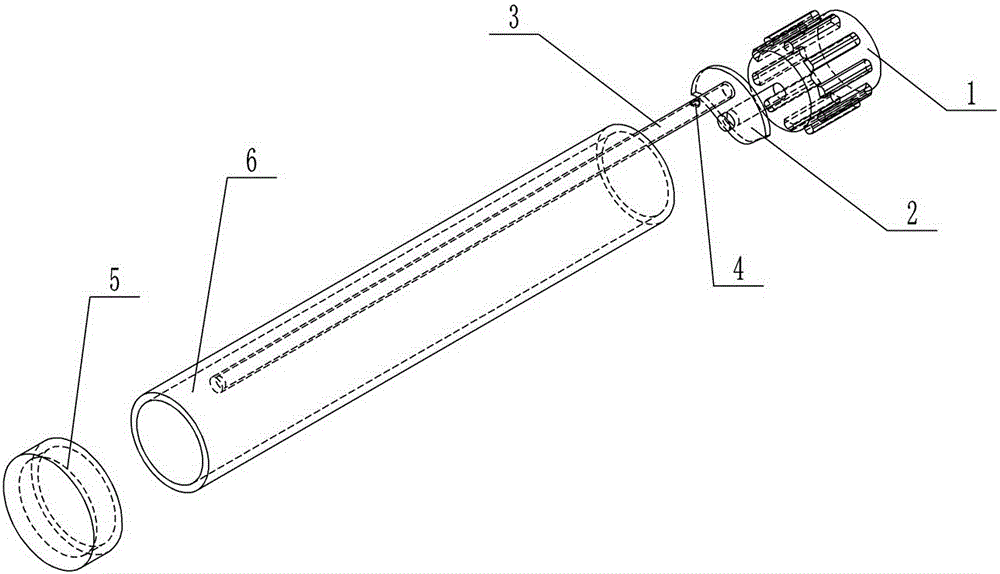

[0016] The reference signs in the accompanying drawings of the specification include: a servo motor 1, an eccentric wheel 2, a polishing rod 3, a water inlet 4, a sealing cover 5, and a stainless steel pipe 6.

[0017] Such as figure 1 , figure 2 As shown, the polishing device for the inner wall of a stainless steel pipe fitting includes a servo motor 1, an eccentric wheel 2, a polishing rod 3 and a sealing cover 5. The eccentric wheel 2 is installed on the output shaft of the servo motor 1, and the distance between the center of rotation of the eccentric wheel 2 and the grinding rod 3 is equal to the inner wall radius of the stainless steel pipe 5. The grinding rod 3 is a hollow grinding rod, and the grinding rod 3 is filled with polycrystalline diamond grinding fluid. The grinding rod 3 is provided with a water outlet hole. The aperture of the water outlet hole is 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com