Fully automatic crystal grinding and polishing all-in-one machine consisting of mineral casting platform

A mineral casting, fully automatic technology, applied to machine tools, grinding/polishing equipment, grinding machines, etc. suitable for grinding the edge of workpieces, it can solve the problems of rusting of cast iron platforms, threats to machine safety, and ineffective effects, etc., to achieve good results The effect of surface quality, safe and reliable operation, and excellent shock absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below by means of the accompanying drawings and examples.

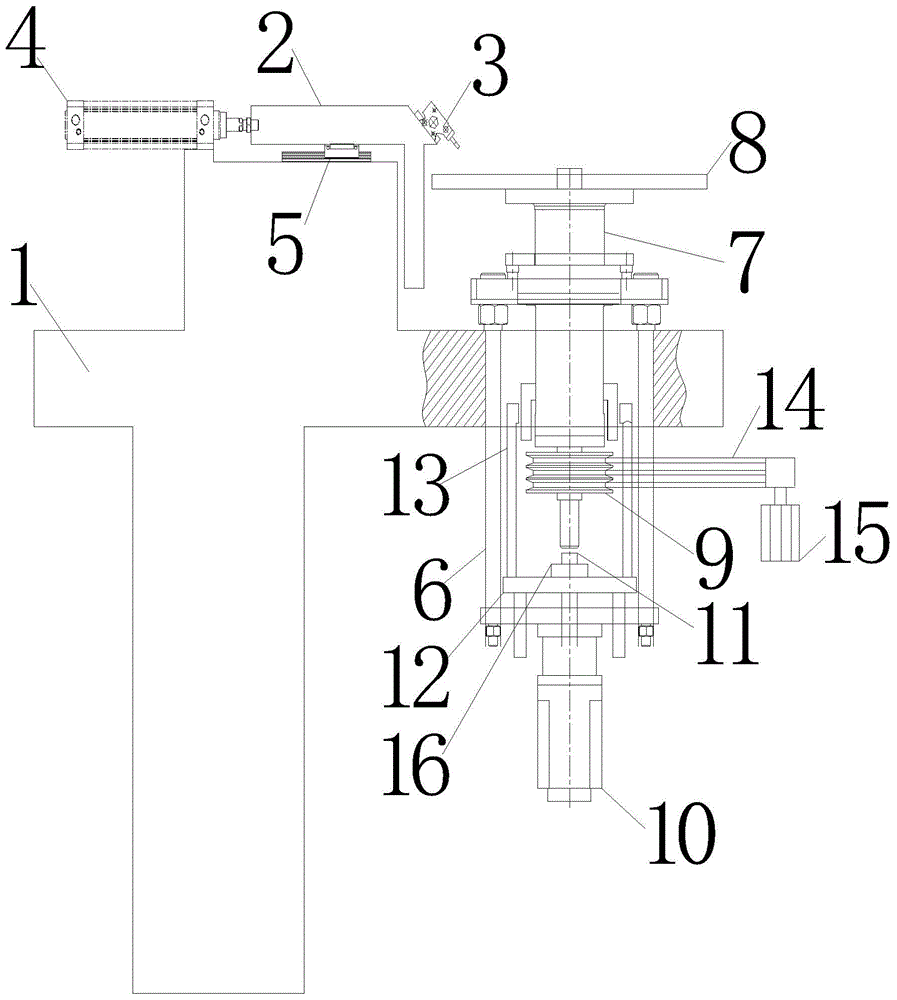

[0017] Such as figure 1 As shown, a fully automatic crystal grinding and polishing machine composed of a mineral casting platform according to the present invention includes a mineral casting platform 1, and an aluminum row horizontal pushing mechanism 2 is arranged on the top of the mineral casting platform 1. An aluminum row 3 is provided at the front portion of the aluminum row flat pushing mechanism 2, a flat pushing cylinder 4 is provided at the rear of the aluminum row flat pushing mechanism 2, and a mineral casting platform 1 is provided on the mineral casting platform 1 below the aluminum row flat pushing mechanism 2. There is a translation guide rail 5, a grinding disc support 6 is provided on the mineral casting platform 1 next to the aluminum row 3, a main shaft 7 is arranged in the grinding disc support 6, a grinding disc 8 is arranged on the upper par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com