Machining method for moving blade with tooth-form arc on rhombus face of blade root

A processing method and technology for moving blades, which are applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., and can solve problems such as dimensional qualification judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

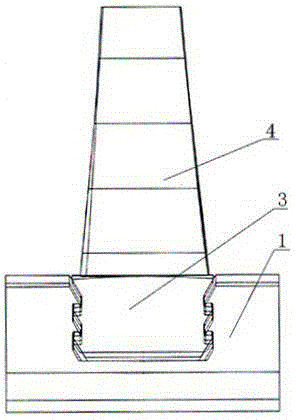

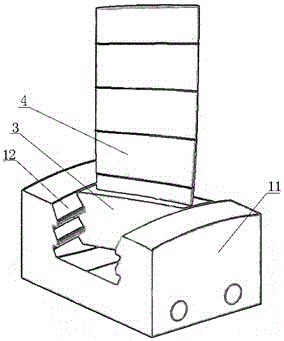

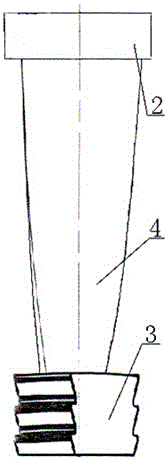

[0019] In order to further illustrate the present invention, introduce below in conjunction with accompanying drawing of description:

[0020] The method for processing a moving blade with a diamond-shaped toothed circular arc blade root, specifically includes the following steps:

[0021] 1) First blank the material, select a cuboid-shaped blank, and confirm that its length is longer than the length of the product by a distance between the blade crown clamping;

[0022] 2) Determine the center at both ends of the cuboid-shaped blank and drill a pinhole at the center point, and stamp the > symbol on the end face of the blade root and the end face of the blade crown, and the direction of the opening is the steam outlet side;

[0023] 3) Out of the hexagon, the parallelism of the two sides of the cuboid blank is ≤0.03, the parallelism of the other two sides is ≤0.03, and the perpendicularity to the two sides is ≤0.05 through milling and grinding;

[0024] 4) The milling machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com