Shaping die for square pipe

A mold and square technology, which is applied in the field of square tube shaping molds, can solve the problems of not being able to meet the matching accuracy requirements of square tubes, affecting the appearance and overall structural strength, and low dimensional accuracy of square tubes, so as to avoid plastic shaping effects, small dimensional tolerances, The effect of easy detachment from the core rod

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

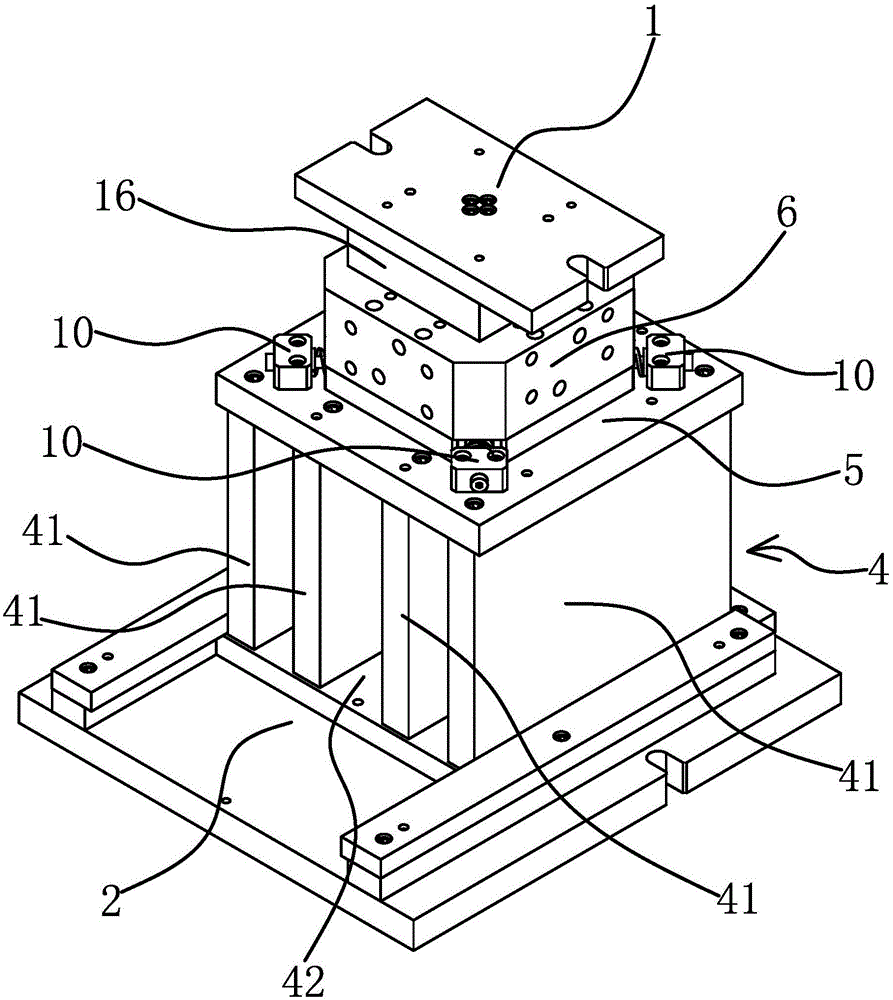

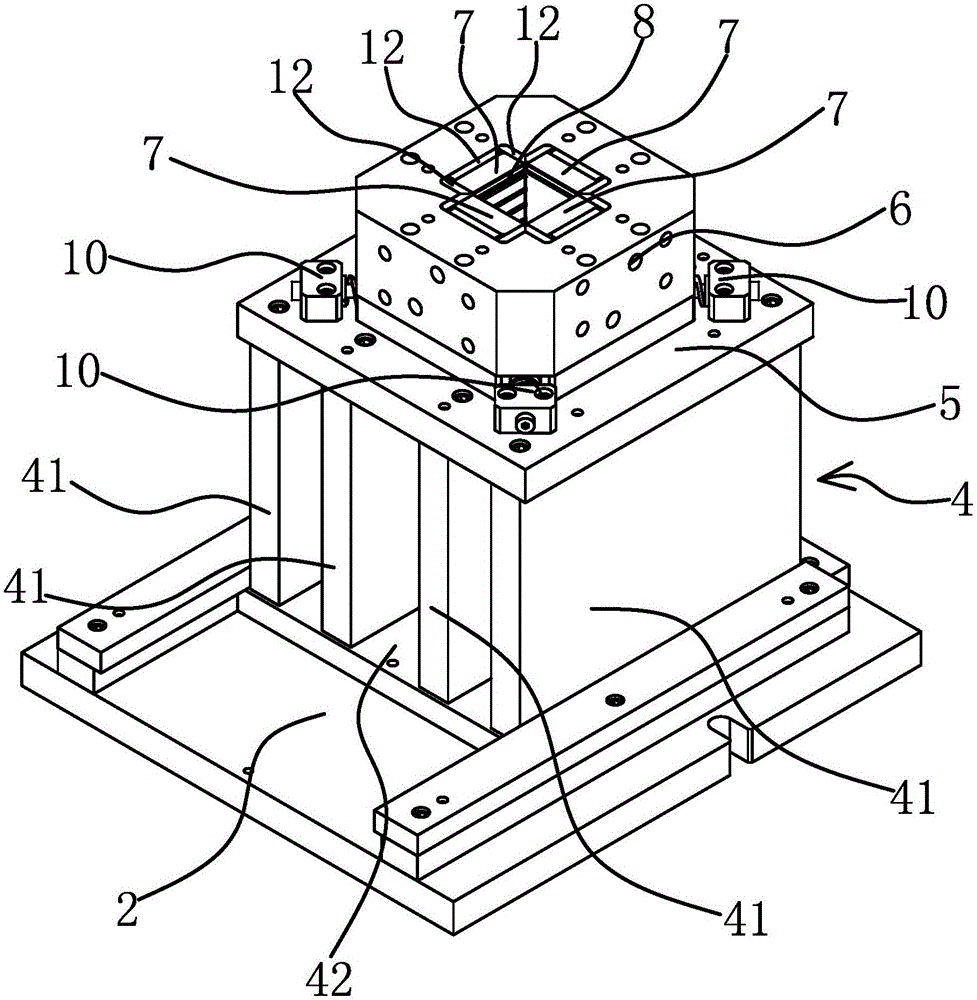

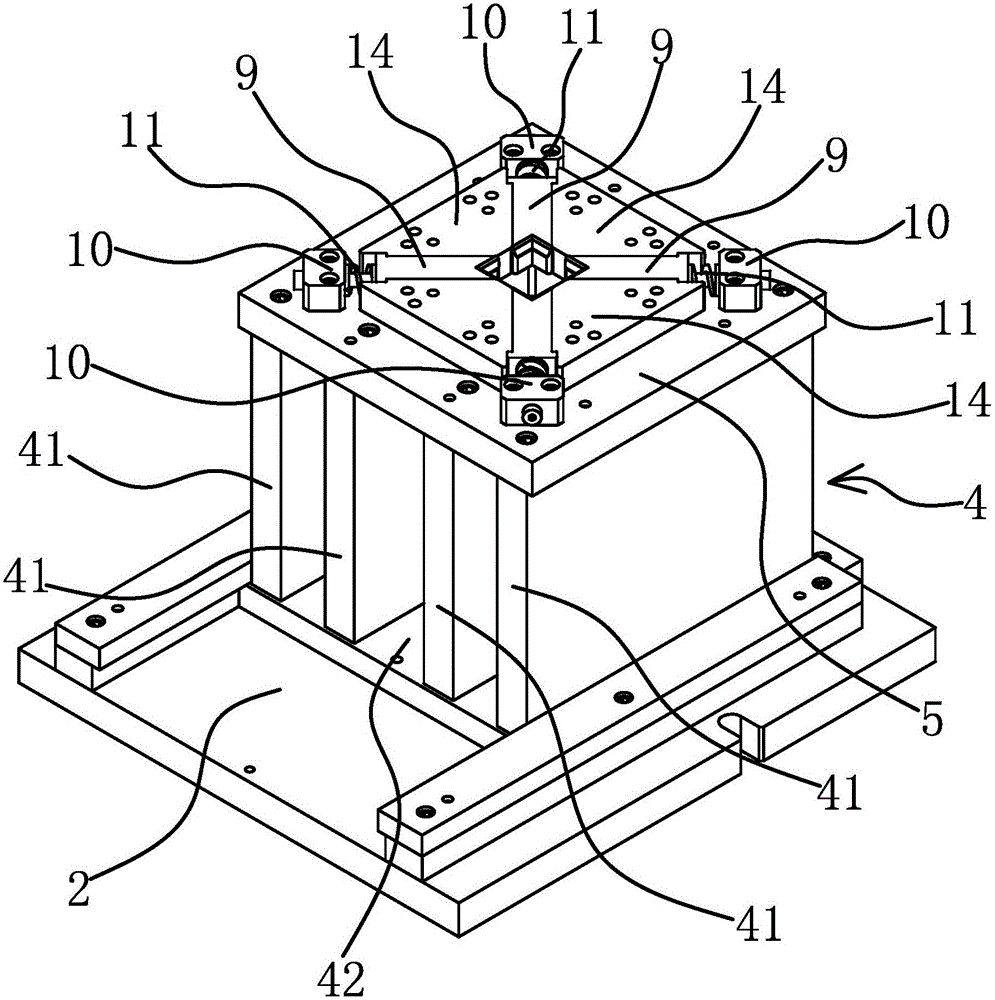

[0036] The square tube shaping mold is used for shaping the square tube on the market or the square tube after bending and welding to reduce the dimensional tolerance of the square tube. When in use, the shaping mold is installed on the press. The square tube shaping mold includes a punch mounting plate 1, a die mounting plate 2, a core rod 3, a support frame 4, a mounting platen 5, a shaping shell 6, a square relief through hole 61, a mounting groove 62, and a shaping block 7 , Roller 8, binder wedge 9, fixed block 10 and elastic member 11.

[0037] Specifically, as figure 1 and Figure 4 As shown, the punch mounting plate 1 and the die mounting plate 2 are arranged up and down, the punch mounting plate 1 is located above the die mounting plate 2, and the punch mounting plate 1 can be connected with the slide block of the press. The cross section of the core rod 3 is square, and the positioning block 16 is fixed on the punch mounting plate 1 , and the core rod 3 is fixed on...

Embodiment 2

[0047] The technical solution in this embodiment is basically the same as that in the first embodiment, except that in this embodiment, the core rod 3 is not sleeved with an extension sleeve 17 . When the press drives the core rod 3 to exit, the square tube 18 is subjected to the pressing force of the pressing wedge 9, and the square tube 18 is applied to the square tube 18 by hand or other auxiliary equipment on the surface of the square tube 18. The pressing force and the action The force makes the square tube 18 separate from the core rod 3 to realize the blanking of the square tube 18.

Embodiment 3

[0049] The technical solution in this embodiment is basically the same as the technical solution in the first embodiment, except that in this embodiment, the elastic member 11 is a compression spring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com