Protective operating gown

A surgical gown and the same technology, applied in protective clothing, clothing, clothing, etc., can solve the problems of inconvenient cleaning of clothes, cross-infection, missing laces, etc., and achieve the effect of saving dressing time, preventing skin contact, and convenient wearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

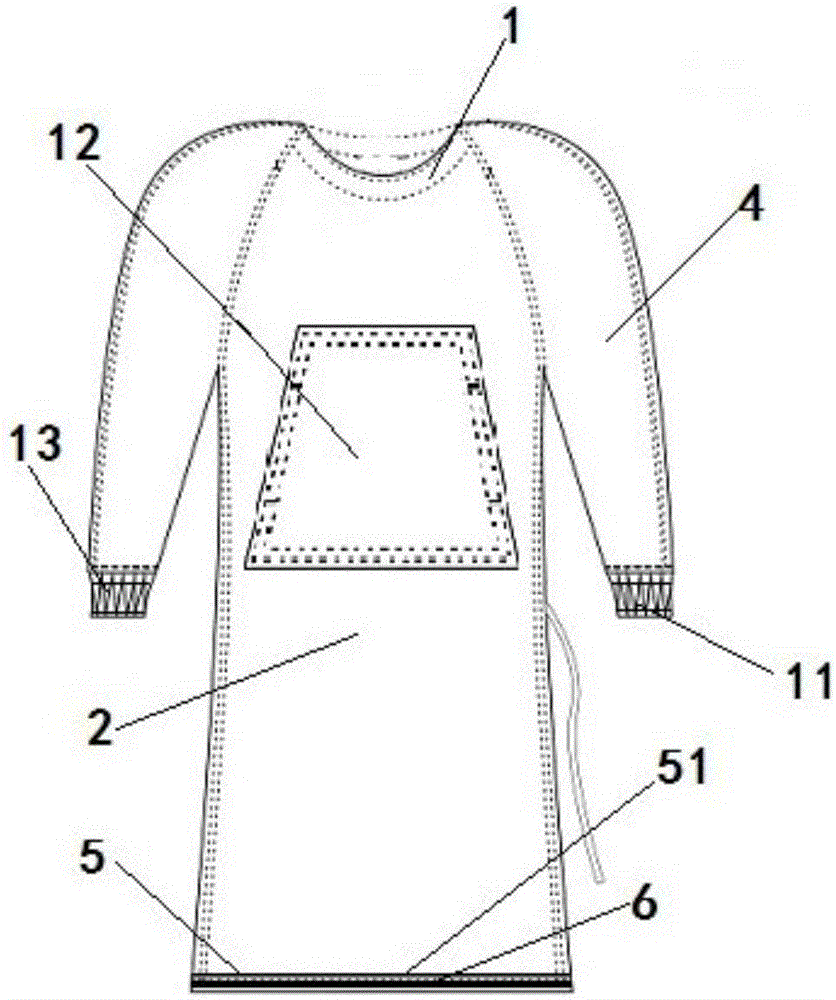

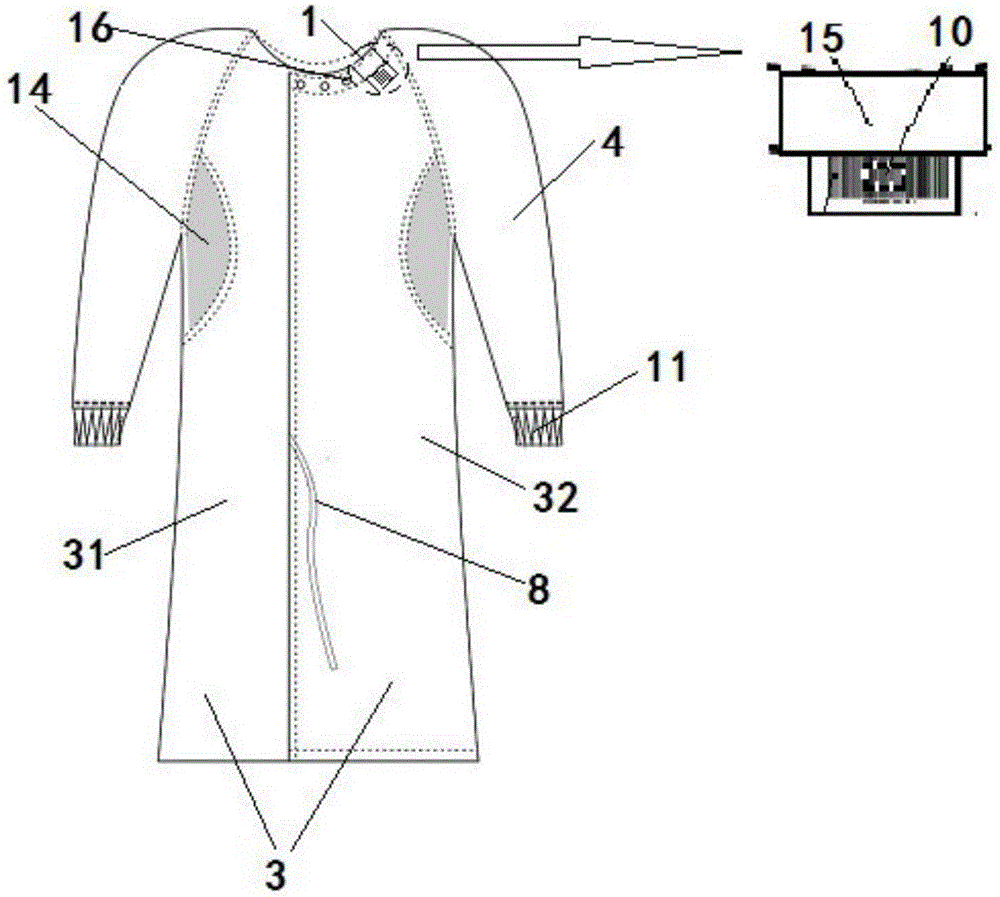

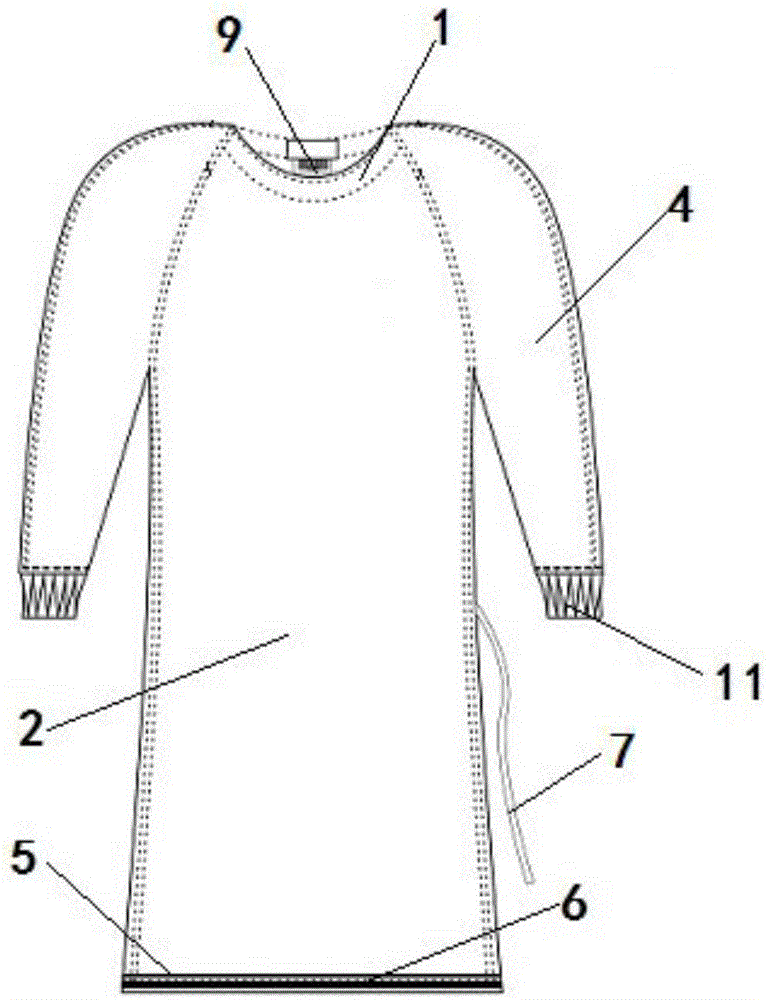

[0033] Such as figure 1 with 2 As shown, the present invention relates to a protective surgical gown, comprising: a collar 1 , a front panel 2 , a rear panel 3 , sleeves 4 and underarm cloth 14 sewn together. The collar 1, front piece 2, back piece 3 and sleeves 4 are made of long-fiber polyester fiber material, which has excellent characteristics such as continuous wadding, no dust production, water resistance, dust resistance, anti-fouling, anti-static and so on. Underarm cloth 14 adopted is air-permeable, moisture-permeable material, and material water-absorbing performance can reach three times of own weight, breathable and sweat-absorbing, attractive in appearance, comfortable.

[0034] The hem of the front panel 2 is turned upwards to form a liquid storage layer 5, and the liquid storage layer 5 is provided with a water-absorbing material 6 to increase the ability and speed of the liquid storage layer 5 to absorb liquid. In the present embodiment, the water-absorbing ma...

Embodiment 2

[0043] The difference between this embodiment and Embodiment 1 is that the barcode label 9 includes a special rubber washing chip 10 for washing. The surface of the rubber washing chip 10 adopts a laser-printed barcode label, and the rubber washing chip 10 has the same data as the barcode label. The special rubber washing chip 10 technology for washing is used to realize batch medical traceability. The data in the barcode label is consistent with the rubber washing chip 10, which is convenient for hospitals to adopt different traceability systems. Each protective surgical gown has a unique code, and the quality of the manufacturer can be traced, which is convenient for use Patient medical traceability and accurate record of reuse times.

Embodiment 3

[0045] The difference between this embodiment and embodiments 1 and 2 is that the front sheet 2 is a double-layer structure. It can better block the splash of liquid during the operation and prevent the cross-infection of medical staff. The fabric component of the front panel 2 is 99% polyester filament yarn and 1% polyester conductive yarn. It adopts the special design of double-sided weave, and the inner layer is embedded with conductive yarn, which gives the surgical gown a good static dissipation function and can effectively reduce the impact on the surgical gown. The interference of precision electronic medical instruments and the difficulty of absorbing dust meet the high specification requirements of today's medical environment; the outer layer adopts a high-density plain weave structure and TeflonHT (Teflon) surface treatment to reduce the risk of direct or cross-infection of medical personnel. At the same time, it greatly improves the appearance of clothes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com