Method for installing and positioning mega nuclear power stator spring plate

A technology for installation and positioning and spring plate, which is applied in the technical field of generator assembly process, can solve the problems of difficulty in installing the spring plate at the same level, inability to connect and assemble, dislocation of screw holes, etc., so as to save the time of assembling and improve production efficiency. , the effect of high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

[0025] The installation and positioning method of a million-level nuclear power stator spring plate provided by the present invention consists of the following 8 steps:

[0026] Step 1: Make the Pin Bolt.

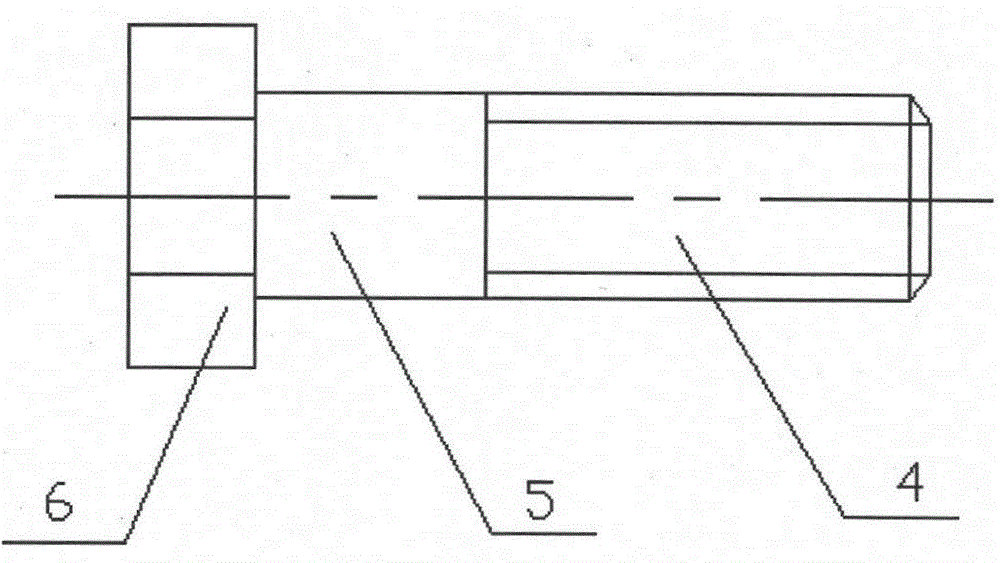

[0027] combine figure 1 , The pin bolt is an overall structure composed of threaded part 4, cylindrical part 5 and hexagonal head part 6 connected in sequence, diameter size: threaded part ≤ cylindrical part < hexagonal head part; the diameter of the cylindrical part is smaller than the diameter of the hole on the spring plate Smaller 0.02 ~ 0.05mm. If the spring plate is Φ35mm, the cylindrical part of the pin bolt is Φ34.95mm~Φ34.98mm. The threaded part on the pin bolt is connected with the threaded hole M30 of the inner stator. 33 pieces of pin bolts need to be processed first, because each spring plate uses 3 pin bolts, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com