Feed, premix and preparation method for alleviating layer vanadium poisoning

A premix and vanadium poisoning technology is applied in the preparation of feed premix, the preparation of feed, and the field of feed premix for relieving vanadium poisoning in laying hens, and can solve the damage to the morphological structure of the oviduct of laying hens Sexual and functional normality, affecting egg protein formation and secretion, reducing protein quality, etc., to achieve the effect of improving blood physical and chemical parameters, improving egg production performance, and improving egg quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

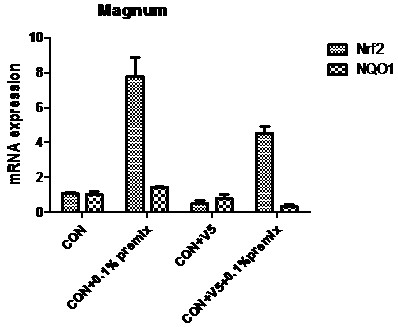

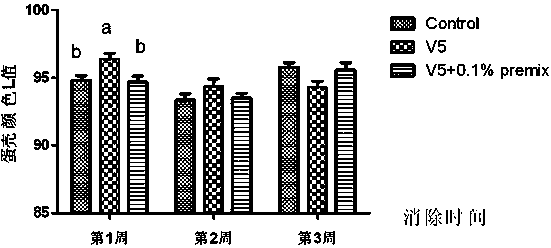

Method used

Image

Examples

preparation example Construction

[0028] The present invention also provides a method for preparing a feed additive for alleviating vanadium poisoning of laying hens, comprising the following steps:

[0029] Step 1. Prepare the premix, prepare the premix, weigh, and weigh the following components according to parts by mass: 10-30 parts of tea polyphenols, 5-10 parts of vitamin C, 1-3 parts of vitamin E, 0.1-1 part of sodium selenite, 0.1-1 part of α-lipoic acid, 60-75 parts of rice bran, and then mix evenly to make a premix;

[0030] Step 2, weighing, weighing the following components according to parts by mass: 50-70 parts of corn, 0.5-2.5 parts of soybean oil, 20-30 parts of soybean meal, 5-10 parts of calcium carbonate, 1 part of calcium hydrogen phosphate -2 parts, 0.1-1 part of table salt, 0.05-0.15 parts of choline chloride, 0.01-0.05 parts of compound multidimensional, 0.10-1 part of mineral additive premix, 0.002-0.003 parts of lysine salt, 0.1-0.2 parts of DL-methionine, 0.005-0.006 parts of threonin...

Embodiment 1

[0033] Weigh the following components according to parts by mass: 20 parts of tea polyphenols, 10 parts of vitamin C, 2 parts of vitamin E, 0.4 part of sodium selenite, 0.5 part of α-lipoic acid, 67.1 parts of rice bran, and then mix uniformly to make a pre- Mixing; weigh the following components according to parts by mass: 60.47 parts of corn, 1.61 parts of soybean oil, 27.17 parts of soybean meal, 8.26 parts of calcium carbonate, 1.19 parts of calcium hydrogen phosphate, 0.4 parts of table salt, 0.1 part of choline chloride, and 0.03 parts of multidimensional compound 0.5 parts, 0.5 parts of mineral additive premix, 0.0026 parts of lysine salt, 0.131 parts of DL-methionine, 0.0054 parts of threonine, 0.021 parts of tryptophan, 0.01 part of 5000 units of phytase, 0.1 part of probiotics, premix 0.1 part of the feed; crush the corn and soybean meal to a particle size of 1500 μm, and then mix the above-mentioned components step by step (mixing coefficient of variation ≤ 5%) to ma...

Embodiment 2

[0035] Weigh the following components according to parts by mass: 10 parts of tea polyphenols, 8 parts of vitamin C, 3 parts of vitamin E, 0.1 part of sodium selenite, 1 part of α-lipoic acid, 60 parts of rice bran, and then mix evenly to make Premix; Weigh the following components according to parts by mass: 50 parts of corn, 2.5 parts of soybean oil, 20 parts of soybean meal, 10 parts of calcium carbonate, 1 part of calcium hydrogen phosphate, 1 part of table salt, 0.05 parts of choline chloride, compound multidimensional 0.05 part, 0.10 part of mineral premix, 0.003 part of lysine salt, 0.1 part of DL-methionine, 0.006 part of threonine, 0.02 part of tryptophan, 0.02 part of phytase 5000 units, 0.2 part of probiotics, premix 0.05 part of the feed; crush the corn and soybean meal to a particle size of 1500 μm, and then mix the above-mentioned components step by step to make a compound feed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com