Cheese grain-containing milk beverage and preparation method thereof

A milk drink and cheese technology, applied in dairy products, milk preparations, applications, etc., can solve the problems affecting the taste and texture of cheese grains, and achieve the effects of being conducive to preservation, preventing fat from floating up, and preventing water absorption and swelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

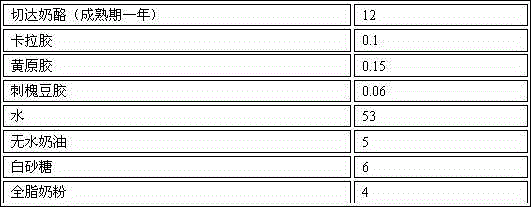

[0013] The raw materials of cheese grains are as follows: (unit: kg)

[0014]

[0015] The raw materials of milk beverage base are as follows: (unit: kg)

[0016]

[0017] Preparation.

[0018] a) Put the raw material of cheese granules into the melting pot for emulsification, and the emulsification temperature is 85°C.

[0019] b) Stirring, the stirring speed is 800rpm, and the stirring time is 15min.

[0020] c) Then heat to 140° C. and continue stirring at a rotation speed of 1200 rpm for 2 minutes.

[0021] d) cooling to 20°C under aseptic conditions, and dicing to make cheese grains.

[0022] e) Preheat the water in the raw materials of the milk beverage base to 50°C, then add other raw materials, set the volume to 1000ml, and perform homogenization, the homogenization pressure is 20Mpa, and the temperature is 60°C to prepare the milk beverage base.

[0023] Add cheese grains into the aseptic tank, the milk drink base material and cheese grains are transported t...

Embodiment 2

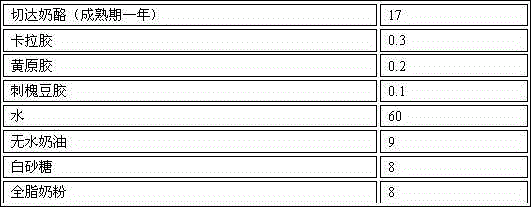

[0025] The raw materials of cheese grains are as follows: (unit: kg)

[0026]

[0027] The raw materials of milk beverage base are as follows: (unit: kg)

[0028]

[0029] Preparation.

[0030] a) Put the raw material of cheese granules into the melting pot for emulsification, and the emulsification temperature is 90°C.

[0031] b) stirring, the stirring speed is 700rpm, and the stirring time is 10min.

[0032] c) Then heat to 140°C and continue stirring, the stirring speed is 1200rpm, and the stirring time is 2min.

[0033] d) cooling to 20°C under aseptic conditions, and dicing to make cheese grains.

[0034] e) Preheat the water in the raw materials of the milk beverage base to 50°C, then add other raw materials, set the volume to 1000ml, and perform homogenization, the homogenization pressure is 25Mpa, the temperature is 60°C, and the milk beverage base is prepared.

[0035] f) Add cheese grains into the aseptic tank, the milk drink base material and cheese grain...

Embodiment 3

[0037] The raw materials of cheese grains are as follows: (unit: kg)

[0038]

[0039] The raw materials of milk beverage base are as follows: (unit: kg)

[0040]

[0041] Preparation.

[0042] a) The raw materials of cheese granules are put into the melting pot for emulsification, and the emulsification temperature is 90°C.

[0043] b) stirring, the stirring speed is 1000rpm, and the stirring time is 10min.

[0044] c) Then heat to 145°C and continue stirring, the stirring speed is 1200rpm, and the stirring time is 2min.

[0045] d) cooling to 20°C under aseptic conditions, and dicing to make cheese grains.

[0046] e) Preheat the water in the raw materials of the milk beverage base to 50°C, then add other raw materials, set the volume to 1000ml, and perform homogenization, the homogenization pressure is 25Mpa, the temperature is 60°C, and the milk beverage base is prepared.

[0047] f) Add cheese grains into the aseptic tank, the milk drink base material and cheese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com