High-voltage linear constant-current LED drive circuit

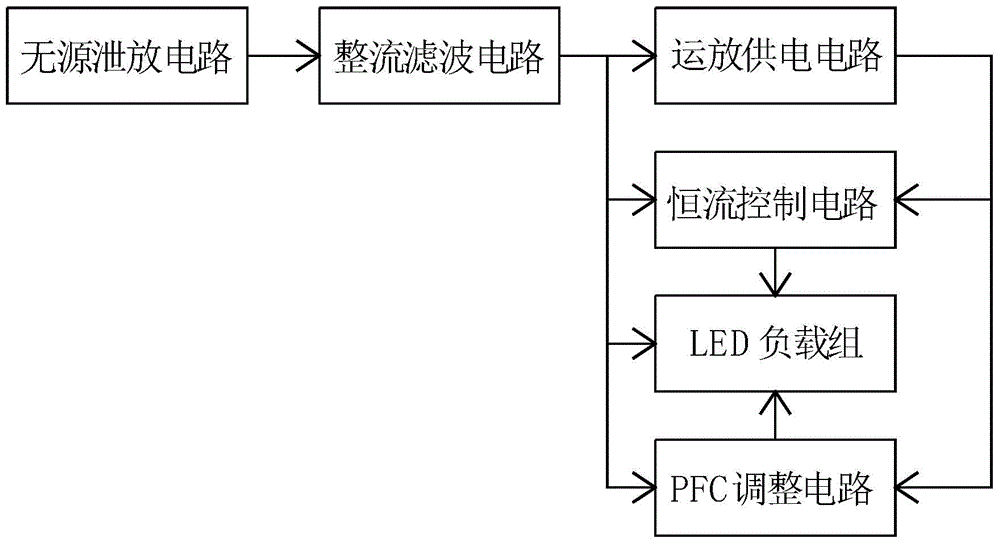

A technology of LED driving and constant current control circuit, which is applied in the direction of electric lamp circuit arrangement, electric light source, lighting device, etc., can solve the problems of low power factor, increased production cost, poor linear adjustment rate, etc., and achieves a simple and reasonable circuit structure, reducing The cost of the whole lamp and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

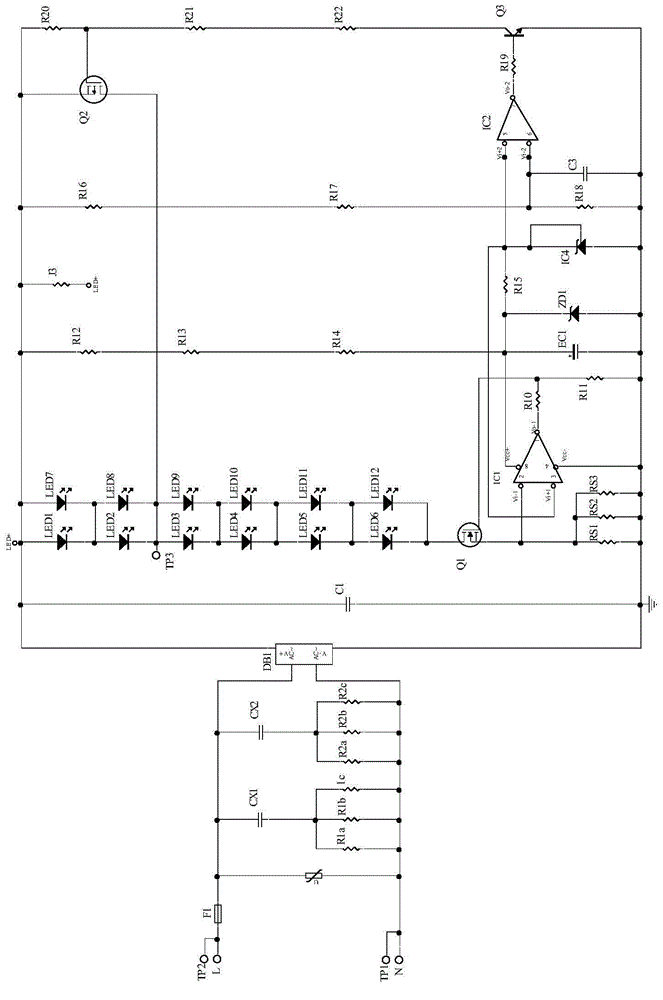

[0027] Such as figure 2 As shown, in this embodiment, the operational amplifier power supply circuit includes series-connected resistors R12, R13, R14, and a capacitor EC1. The resistor R12 is connected to the voltage bus output by the rectifier filter circuit. The resistor R14 is connected to the capacitor EC1. Ground. The PFC adjustment circuit includes an operational amplifier IC2, a voltage reference IC4, a first sampling resistor, switching tubes Q3 and Q2, the switching tube Q3 is a triode, the switching tube Q2 is a P-type MOS tube, and the resistor R14 is connected to The connection point of the capacitor EC1 is connected to the operational amplifier IC2 through a resistor R15 to supply power; the anode of the voltage reference IC4 is grounded, and the cathode is connected to the positive phase input terminal of the operational amplifier IC2, which is the positive phase of the operational amplifier IC2 The input terminal provides a fixed voltage reference value, such a...

Embodiment 2

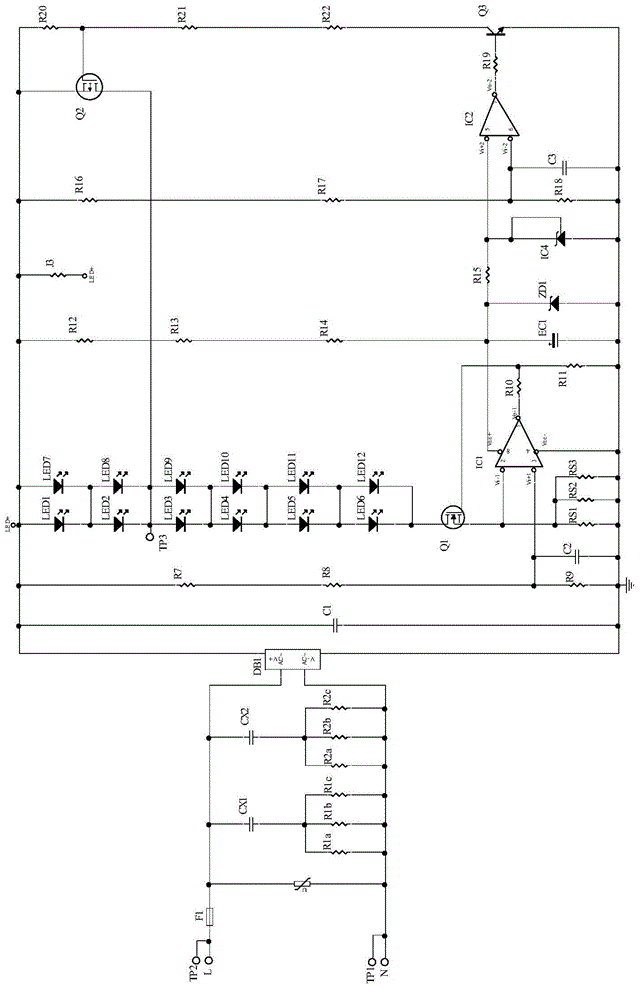

[0034] Such as figure 1 with image 3 As shown, the difference between this embodiment and Embodiment 1 is that the constant current control circuit includes a second sampling resistor, a sampling resistor RS, a switch Q1 and an operational amplifier IC1. The connection point of the resistor R14 and the capacitor EC1 in the operational amplifier power supply circuit is connected to the power supply terminal of the operational amplifier IC1 for power supply. The second sampling resistor includes resistors R7, R8, R9 connected in series, and the resistor R7 is connected to the The voltage bus bar output by the rectifier filter circuit, the resistor R9 is grounded; the voltage on the resistor R9 is connected to the non-inverting input terminal of the operational amplifier IC1; the anode of the LED load group is connected to the voltage output by the rectifier filter circuit Bus, the negative pole of the LED load group is connected to the drain of the switching tube Q1, the source o...

Embodiment 3

[0037] Such as figure 1 with Figure 4 As shown, the difference between this embodiment and embodiment 2 is that a power compensation circuit is added to the circuit of embodiment 1. The power compensation circuit includes an operational amplifier IC3, and the voltage on the resistor R9 is passed through the power compensation circuit. After processing, connect the non-inverting input terminal of the operational amplifier IC1. The connection point of the resistor R14 and the capacitor EC1 in the operational amplifier power supply circuit is connected to the power supply terminal of the operational amplifier IC3, and the output terminal of the operational amplifier IC3 is connected to the non-inverting input terminal of the operational amplifier IC1 through the resistor R26 to supply power for the operational amplifier IC1. The resistor R9 is connected to the inverting input terminal of the operational amplifier IC3 through a resistor R24. The non-inverting input terminal of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com