Pretightening force PTC electric heater

An electric heater and pre-tightening force technology, applied in the direction of ohmic resistance heating parts, etc., can solve the problems of increasing resistance, reducing contact reliability, reducing thermal efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

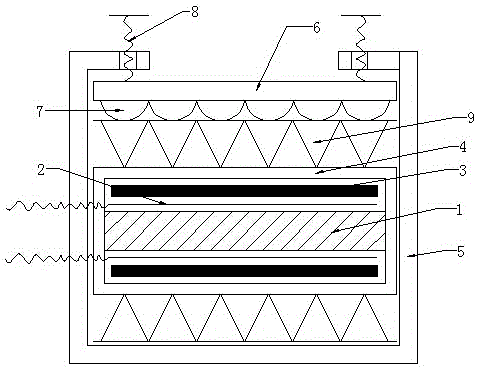

[0015] The preload PTC electric heater of the present invention includes a PTC element 1, and the PTC element 1 is preferably a PTC ceramic sheet. The outer periphery of the electrode 2 is wrapped with an insulating film 3 and then pressed into a square tube 4 to form the main body of the electric heater. The square tube 4 is preferably an aluminum alloy square tube, and also includes a frame body 5. Inside the frame body 5, there is also a pressing plate 6 located between the frame body and the square tube 4 of the main body of the electric heater. The pre-tightening bolt 8, the frame body 5 is provided with a bolt hole facing the upper part of the electric heater body in the frame, the pre-tightening bolt 8 is pressed on the upper surface of the pressure plate 6 through the bolt hole, and the pressure plate 7 is pressed by the pre-tightening bolt 8. So that the elastic layer of the pressing plate 7 is pressed on the main body of the electric heater, when thermal expansion or...

Embodiment 2

[0017] The preload PTC electric heater of the present invention includes a PTC element 1, and the PTC element 1 is preferably a PTC ceramic sheet. The outer periphery of the electrode 2 is wrapped with an insulating film 3 and then pressed into a square tube 4 to form the main body of the electric heater. The square tube 4 is preferably an aluminum alloy square tube, and also includes a frame body 5. The cross-sectional shape of the frame body 5 It is a C-shaped structure so that the frame body 5 forms an opening, the electric heater main body is arranged in the frame body 5, the heat sink 9 is arranged outside the square tube 4 of the electric heater main body, and the frame body 5 is also provided with The pressure plate 6 between the opening of the frame body and the heat sink 9, the bottom surface of the pressure plate 6 is provided with an elastic layer 7, and also includes a pre-tightening bolt 8 that can compress the upper surface of the pressure plate 6, and both sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com