Heat dissipation method for a power battery pack

A technology of power battery pack and heat dissipation method, applied in the field of electronics, can solve problems such as affecting battery life and achieve the effect of convenient management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

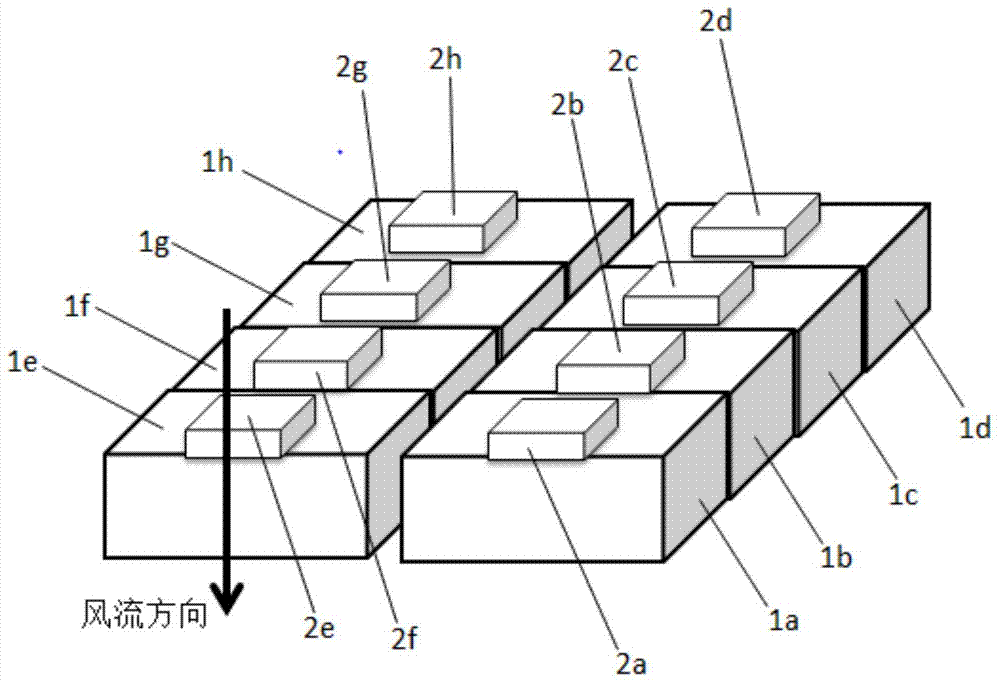

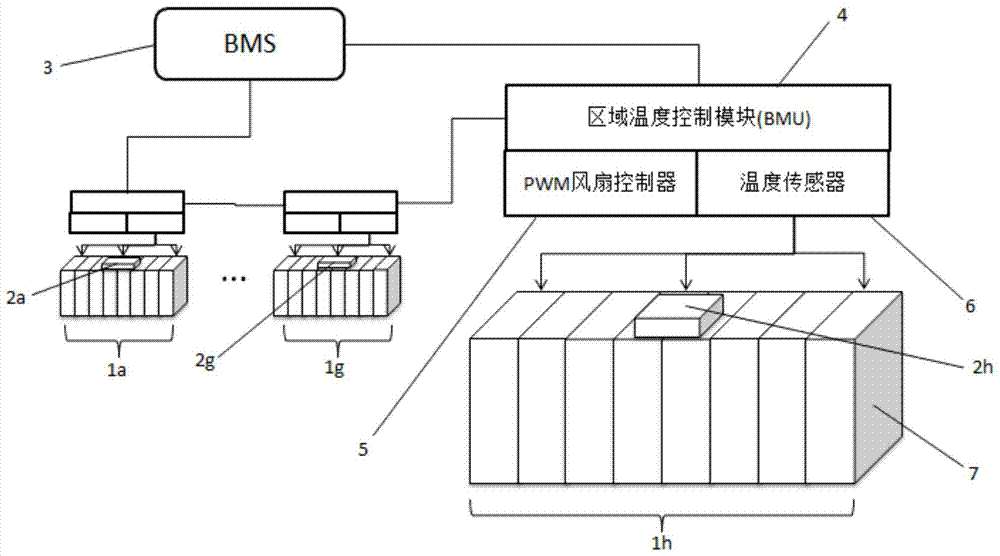

[0026] Such as figure 1 and figure 2 As shown, a heat dissipation device for a power battery pack, the battery pack includes a plurality of interconnected battery modules 1 (1a, 1b, to 1h in the figure) and a main control unit BMS3, and the battery module 1 has 8 One, according to the needs in the example, the number is not limited, the main control unit is the battery management system is a known technology, the battery module 1 is equipped with a cooling fan 2 (2a, 2b, to 2h in the figure), There are 8 in the figure, and the number is the same as that of the battery module 1 as required in the example. Can be applied to battery packs with irregular shapes. At the same time, a standardized design of the battery module 1 can be carried out, which facilitates group configuration of battery packs of different capacities, and the components of the battery module 1 do not need to be molded again; design, development and manufacturing costs can be reduced.

[0027] At the same ...

Embodiment 2

[0037] A heat dissipation method for a power battery pack, based on the device of Embodiment 1, the method includes:

[0038] When the communication between the battery module control unit BMU4 and the main control unit BMS3 is normal, the battery module control unit BMU4 collects the temperature of the battery module 1 and sends it to the main control unit BMS3, and the main control unit BMS3 issues a cooling command to the cooling fan 2. Control; control the opening and closing of the cooling fan 2, and control its speed.

[0039] When the communication between the battery module control unit BMU4 and the main control unit BMS3 is interrupted, the battery module control unit BMU4 directly controls the cooling fan 2 of a single battery module 1 according to the collected temperature of the battery module 1, and controls the cooling fan 2 The opening and closing of the battery, as well as controlling its rotational speed, thereby controlling the temperature of multiple battery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com