Connection structure of flexible-package lithium ion battery module

A lithium-ion battery and module connection technology, applied to structural parts, battery pack parts, circuits, etc., to achieve the effects of ensuring welding quality, simplifying assembly process, and simple positioning structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

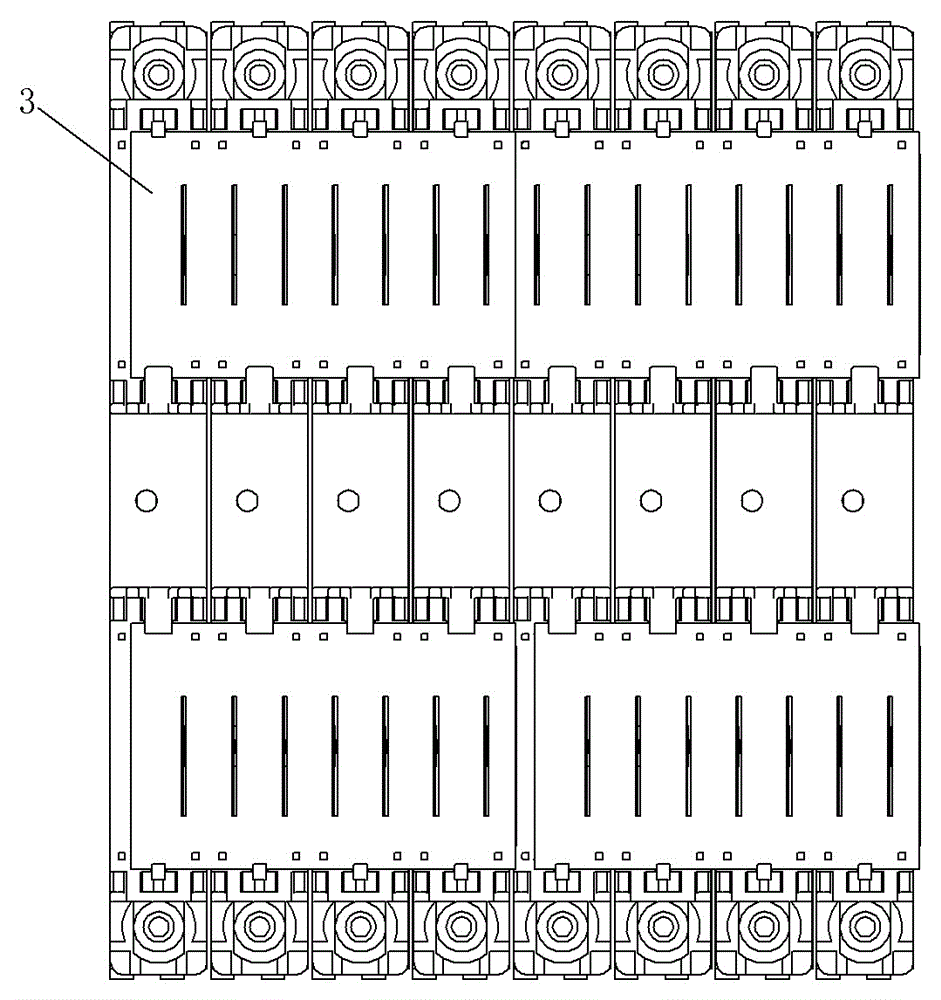

[0018] Such as Figure 1 to Figure 3 As shown, an embodiment of a soft-pack lithium-ion battery module connection structure includes a plurality of battery cells 1 arranged in parallel and a bus bar 3 located above the battery cells and electrically connected to the tabs of the battery cells. A plurality of battery cells are arranged in sequence along the left and right directions, and the bus bar 3 also extends along the left and right directions. The connection structure of the soft-pack lithium-ion battery module also includes an insulating grid plate 2 arranged under the bus bar 3 and fixedly assembled with the battery cells. The insulating grid 2 is provided with a tab hole 202 corresponding to the tab 4 of the cell 1 for the tab to pass through. The top of the tab hole 202 has a bend that is close to the insulation grid. The bent portion on the upper side of the plate 2 , the bus bar 3 has a lower side that is crimped on the bent portion of the tab 4 and welded and fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com