Uniform electric field type robot tactile sensor and detection method thereof

A tactile sensor and uniform electric field technology, applied in the field of sensing, can solve the problems of many factors that need to be controlled in the manufacturing process of composite thin film electrodes, difficulty in ensuring that the electrodes meet the requirements, and complicated preparation processes for sensitive materials, etc., so as to reduce CPU calculation. Time, simple structure, simple signal extraction and processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

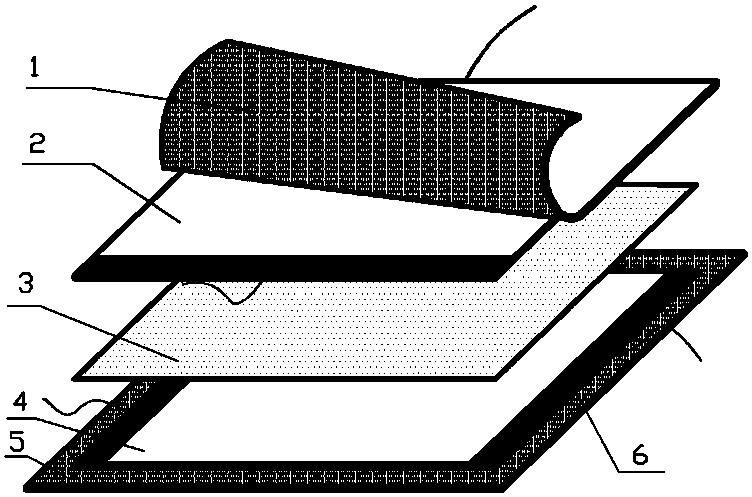

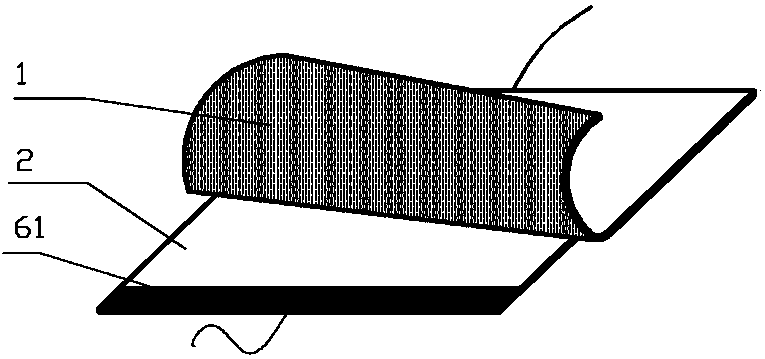

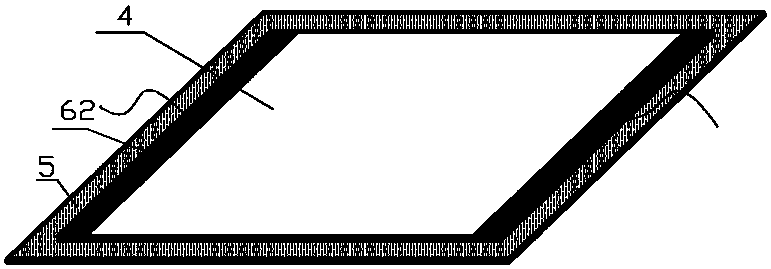

[0029] This embodiment provides a kind of robot tactile sensor of uniform electric field type, such as Figure 1-Figure 4 As shown, it includes an upper flexible layer 11, a mesh spacer 3 and a lower flexible layer 22, the upper flexible layer 11 and the lower flexible layer 22 are composed of a conductive surface and an insulating surface, and the conductive surface is used as The inner surfaces of the upper flexible layer and the lower flexible layer, the conductive surfaces 1 and 4 of the upper flexible layer and the lower flexible layer are respectively directly attached to the upper and lower sides of the mesh partition; the upper flexible layer and the lower flexible layer Parallel linear electrodes 6 are provided on both opposite sides of the conductive surface, and the linear electrodes 61 of the upper flexible layer and the linear electrodes 62...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com