Automatic adjustable variable speed oil pump

An automatic adjustment and variable speed technology, which is applied in the direction of lubricating pumps, engine components, and engine lubrication, can solve problems such as large power consumption, low average engine speed, and failure to adjust the output oil pressure of the oil pump, so as to reduce hydraulic power. and mechanical power, reduce energy loss, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

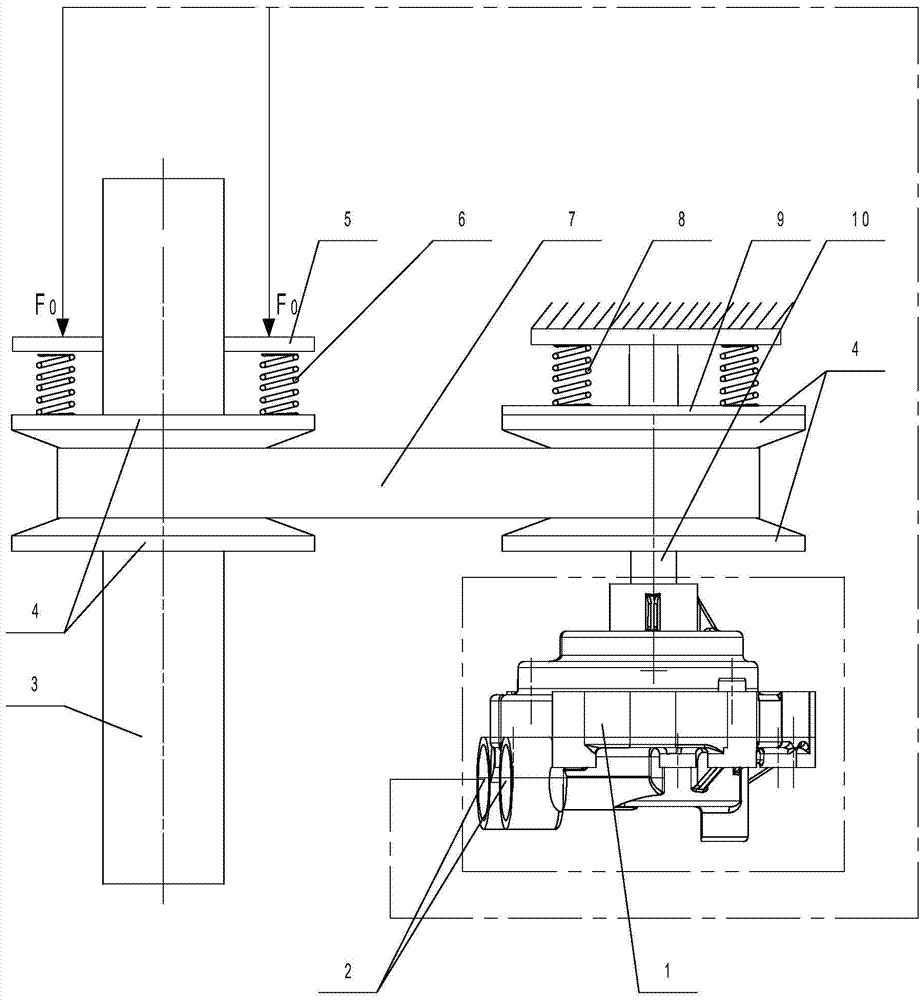

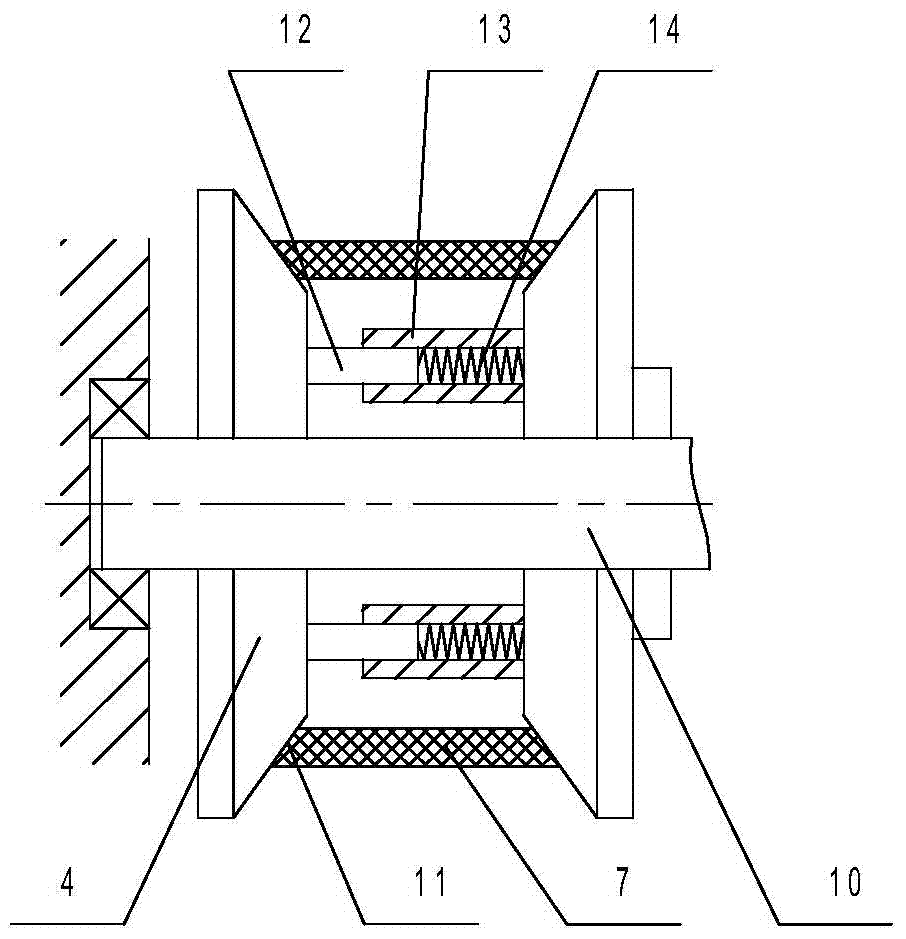

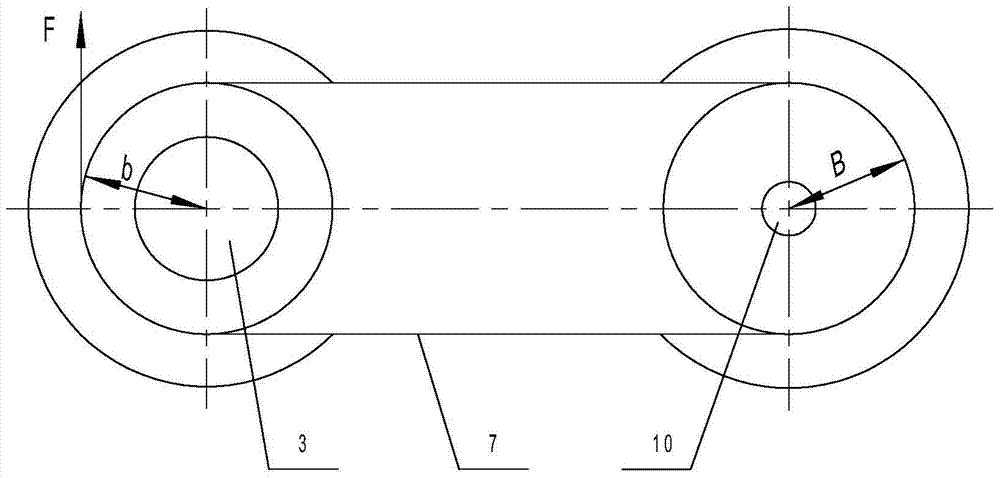

[0023] Depend on figure 1 It can be seen from the schematic structural diagram of the self-adjusting variable speed oil pump of the present invention that it includes an oil pump main body 1 with a rotating shaft 10 and a power output shaft 3 of an engine connected to the rotating shaft 10 through a transmission mechanism. Service port 2 for each lubrication point. The transmission mechanism includes four single-cone rollers 4 and a belt 7, the four single-cone rollers 4 are two pairs, and the conical surfaces of each pair of two single-cone rollers 4 are opposite. Wherein a pair of single-tapered rollers 4 and rotating shaft 10 circumferential limit and sliding fit, and the distance between the two single-tapered rollers 4 is adjusted by the first distance adjustment mechanism; another pair of single-tapered rollers 4 and the power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com