Anticorrosion method for improving anticorrosion effect and fixing rigid polyvinyl chloride plate through fusible interlining

A technology of rigid PVC and PVC sheets, applied in chemical instruments and methods, layered products, construction, etc., can solve problems such as large influence, deformation, weld leakage, etc., and achieve the effect of high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

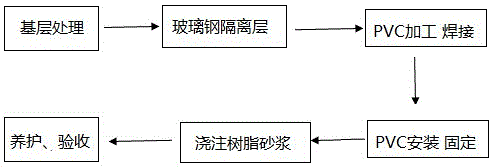

Method used

Image

Examples

Embodiment 1

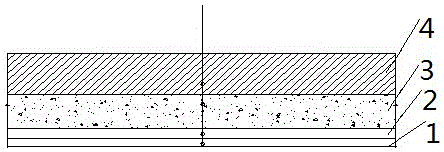

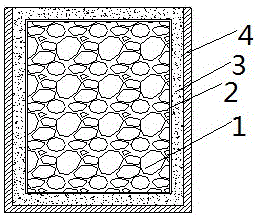

[0023]The hard polyvinyl chloride plate used in a mixing tank is 25mm thick, and the mesh-shaped holes above it are 10mm in diameter, 300mm in diameter, and 40mm thick in resin mortar; remove the original anti-corrosion layer; pickling neutralization: use concentration < 10% Wash the original base layer with sodium hydroxide solution, neutralize the acid-containing electrolyte in the base layer with sodium hydroxide solution, and then rinse with water for two times; drying treatment: bake with a gasoline blowtorch until the base layer is dry, and do a drying experiment for the base layer. until there is no moisture in the base layer. Base-level sandblasting cleaning treatment: use a high-pressure air compressor to spray quartz sand on the base-level, and thoroughly clean the surface dirt and residual crystals. Base repair sand leveling, using aluminate cement + coarse sand, the ratio is 1:2.5, repairing mortar parts, blowtorch secondary drying treatment; grinder grinding: the ...

Embodiment 2

[0025] In another mixing pool, a hard polyvinyl chloride plate with a thickness of 10mm is used, and the mesh-shaped holes above it are drilled with a diameter of 6mm, an aperture spacing of 400mm, and a resin mortar thickness of 20mm; the original anti-corrosion layer is removed, and pickling and neutralization: use concentration < 10% Sodium hydroxide solution washes the original base, neutralizes the acid-containing electrolyte in the base with sodium hydroxide solution, and then rinses with water for two times; drying treatment, baking with a gasoline blowtorch until the base is dry, and doing the drying experiment of the base. Until there is no moisture in the base layer; base layer sandblasting cleaning treatment: use a high-pressure air compressor to spray quartz sand on the base layer, and thoroughly clean the surface dirt and residual crystals. Base repair sand leveling, using aluminate cement + coarse sand, ratio 1:2.5. Repairing of mortar parts, secondary drying of ...

Embodiment 3

[0027] In the third mixing tank, a hard polyvinyl chloride plate with a thickness of 2mm is used, and the mesh-shaped holes above it are drilled with a diameter of 3mm, an aperture spacing of 500mm, and a resin mortar thickness of 10mm; remove the original anti-corrosion layer, and pickling and neutralization: use a concentration of <10% Wash the original base layer with sodium hydroxide solution, neutralize the acid-containing electrolyte and sodium hydroxide solution in the base layer, and then rinse it with water for two times; drying treatment: bake with a gasoline blowtorch until the base layer is dry, and do the drying experiment of the base layer . until there is no moisture in the base layer. Base-level sandblasting cleaning treatment: use a high-pressure air compressor to spray quartz sand on the base-level, and thoroughly clean the surface dirt and residual crystals. Base repair sand leveling, using aluminate cement + coarse sand, ratio 1:2.5, repairing mortar parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com