A mold bag grouting device

A technology of grouting device and mold bag, which is applied in the direction of construction and infrastructure engineering, etc. It can solve the problems of difficulty in lower placement, inability to realize water blocking, low success rate, etc., and achieve easy and convenient water plugging and fast water plugging in lower mold bag Water effect, effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

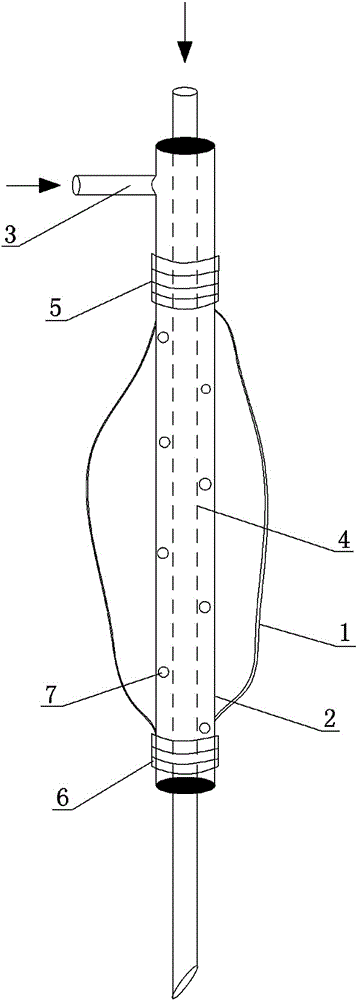

[0012] Such as figure 1 As shown, a mold bag grouting device includes a mold bag 1, an outer pipe 2, a mold bag grouting pipe 3, and a rock mass grouting pipe 4. The rock mass grouting pipe 4 is arranged through the outer pipe 2, and the outer pipe The two ends of 2 and the corresponding rock mass grouting pipe 4 are welded to form a gap between the rock mass grouting pipe 4 and the outer pipe 2, and the outer pipe 2 is inserted into the mold bag 1 from the upper end of the mold bag 1, and the rock mass grouting pipe 4 and the outer pipe 2 are inserted into the mold bag 1. The body grouting pipe 4 is set through the mold bag 1, one end of the mold bag 1 is set on the upper end of the outer tube 2, the other end of the mold bag 1 is set on the lower end of the outer tube 2, and the upper end of the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com