Device and method for tensioning and reinforcing double layers of pre-stress carbon fiber sheet at same time

A carbon fiber cloth and tensioning device technology, used in bridge reinforcement, bridge maintenance, erection/assembly of bridges, etc. Pulling is convenient and quick, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

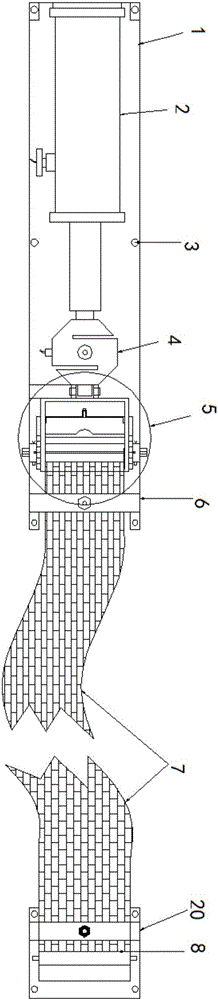

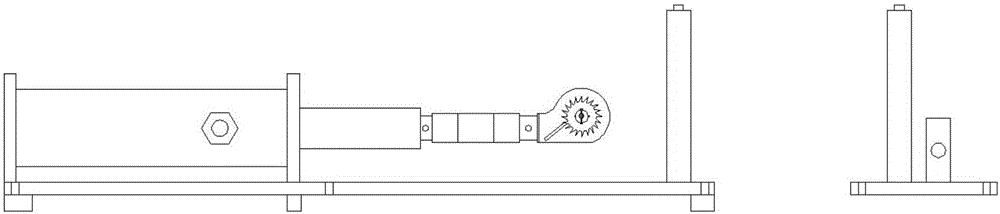

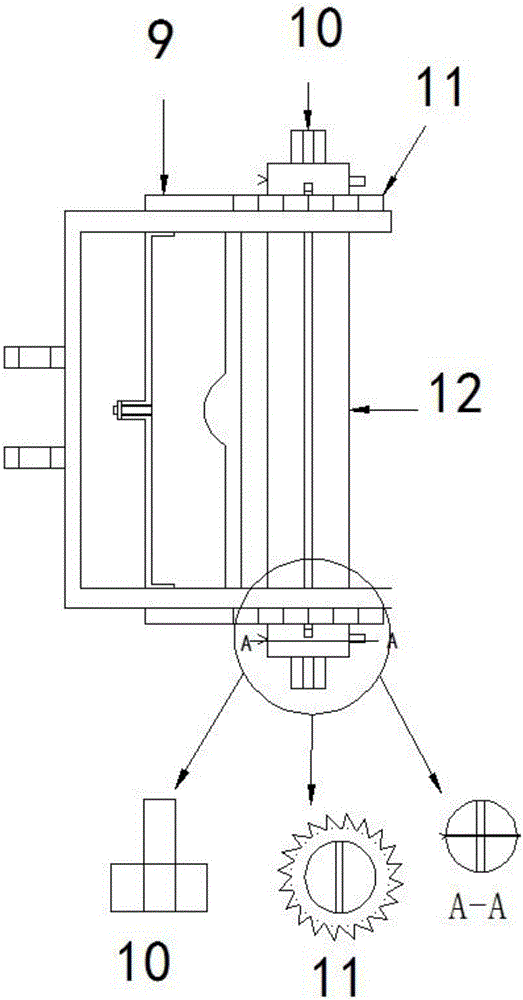

[0057] figure 1 It is a schematic diagram of tensioning device and rolling device of the present invention, figure 2 An enlarged view of the carbon fiber cloth rotation locking device, Figure 4 It is a schematic diagram of the carbon fiber cloth pressing device. As shown in the figure, the prestressed carbon fiber cloth double-layer simultaneous tensioning and anchoring measure system of this embodiment includes a first anchoring steel plate, a tensioning device and a rolling device.

[0058] The tensioning device comprises a fixed support 1, a jack 2, a tension sensor 4, a carbon fiber cloth rotation locking device 5 and a first pressing device 6. The tension sensor 4 can monitor the tension stress size through the display in real time. Carbon fiber cloth rotation locking device 5, the carbon fiber cloth rotation locking device mainly comprises a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com