Profile steel and reinforced concrete slab assembled light composite beam bridge and construction method thereof

A reinforced concrete slab and assembled technology, which is applied in the direction of erecting/assembling bridges, portable bridges, bridges, etc., can solve problems such as difficult construction, delay in construction period, and difficult installation, so as to improve construction safety and construction speed, Guaranteed connection strength and reduced construction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] This embodiment focuses on the structural features and functions involved in the present invention, and is described in detail as follows in conjunction with the accompanying drawings:

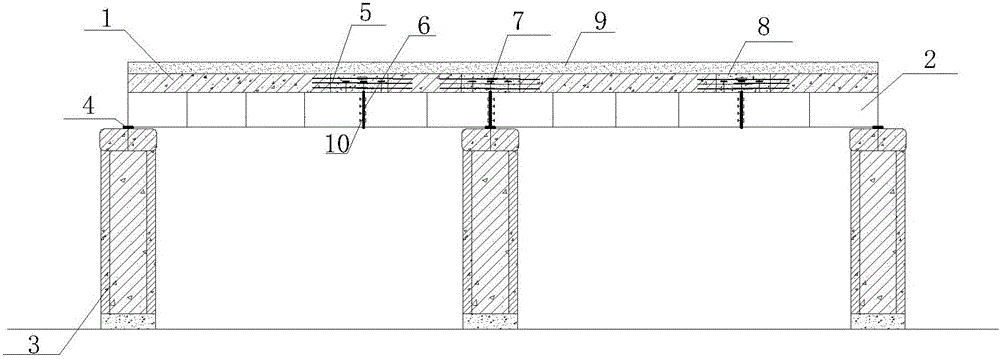

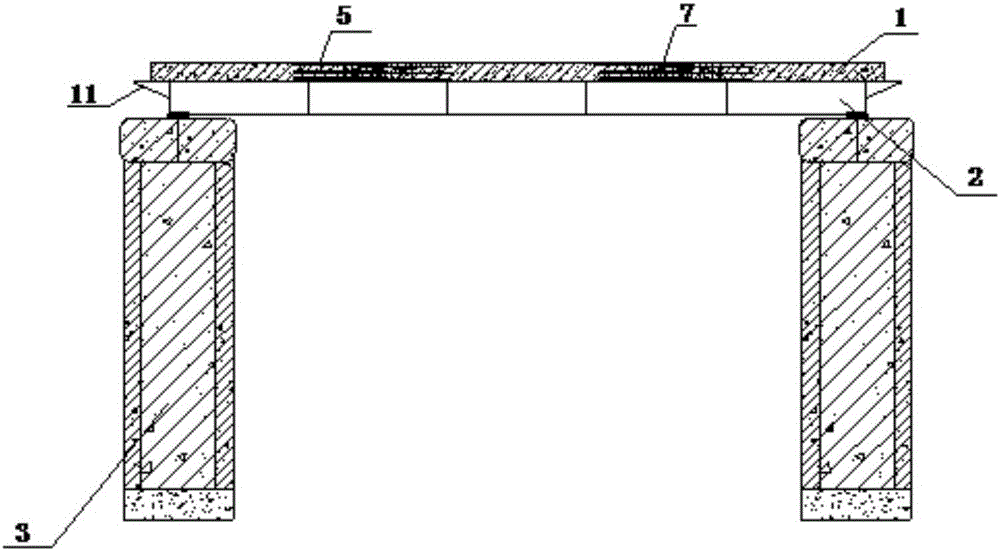

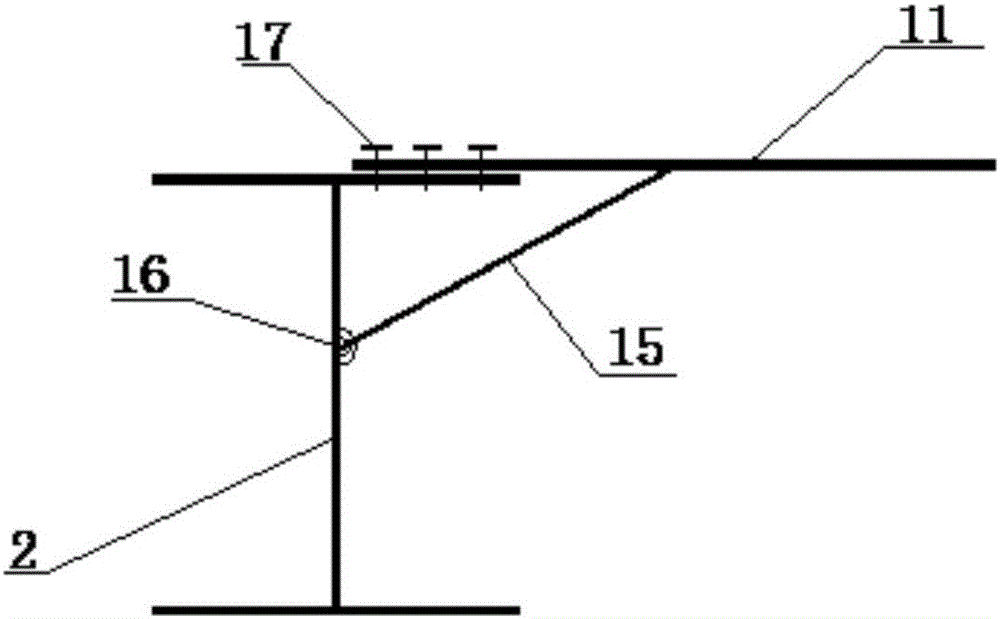

[0032] figure 1 It is an elevation view of a light-duty composite girder bridge assembled with section steel and reinforced concrete slabs. Such as figure 1 As shown, the light-duty composite girder bridge assembled with section steel and reinforced concrete slab is mainly composed of prefabricated reinforced concrete slab 1, section steel beam 2, and prefabricated pier column 3. The prefabricated pier column 3 serves as the permanent support of the prefabricated reinforced concrete slab 1 and the shaped steel beam 2 , and the shaped steel beam 2 is arranged under the prefabricated reinforced concrete slab 1 , and is fixed with the prefabricated pier column 3 through the bridge support 4 . Figure 8 It is the assembly diagram of steel beams, such as Figure 8 As shown, the shaped s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com