High strength and large specific heat multiphase magnetic cold storage material and preparation method thereof

A cold storage material and high-strength technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of waste and loss of function of rare earth materials, and achieve the effect of improving quality, facilitating processing and molding, and reducing requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

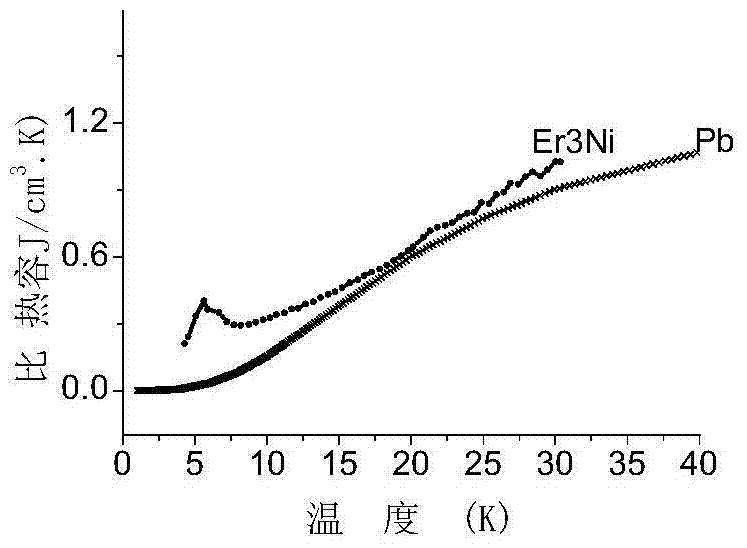

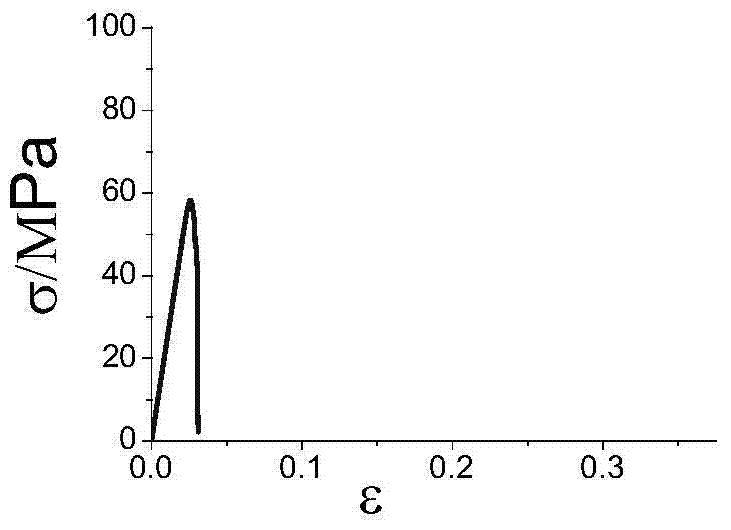

[0051] Using the Er metal raw material with an oxygen content as high as 0.32wt%, using the preparation process of the present invention, the master alloy is placed in the crucible, and the vacuum is evacuated to 5*10 before heating. -3 Pa, then introduce argon gas into the crucible, the pressure of argon gas is 0.06MPa, and then melt the master alloy, let it stand for 30 minutes at 1100 ° C, flow out from the crucible with holes, and leave high oxygen in the crucible content of the master alloy balance. A sample of Example 1 with an Er content of 92 wt %, a Ni content of 7.9 wt % and an oxygen content of 0.1 wt % was obtained. Then put the material into the vacuum annealing furnace, and vacuumize to 8*10 -3 In the state of Pa, heat to 700°C, then introduce 0.05MPa argon, adjust the temperature to 830°C, and anneal for 3 days. Although the oxygen content in the Er metal raw material is very high, the oxygen content of the finally obtained sample of Example 1 of the present i...

Embodiment 2

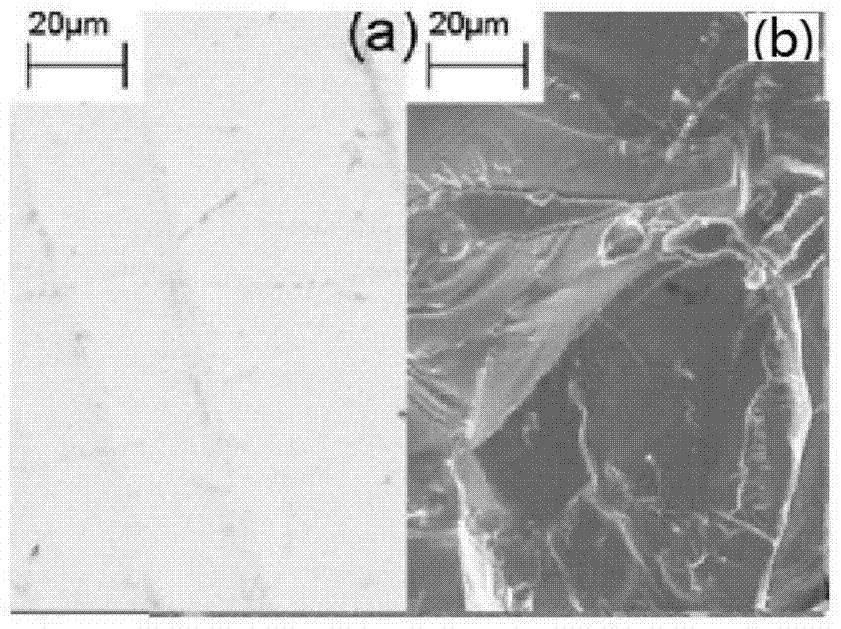

[0053] Ho metal feedstock with an oxygen content up to 0.48 wt% was used. Using the preparation process of the present invention, the master alloy is placed in the crucible, and the vacuum is evacuated to 7*10 before heating. -3 Pa, then introduce argon gas into the crucible, the argon pressure is 0.5Pa, and then melt the master alloy, let it stand at 1120°C for 20 minutes and then cool it in the alumina crucible, and then cut off the cooled master alloy At the top of the high oxygen content, the sample of Example 2 with a Ho content of 65.8 wt%, a Cu content of 34.14 wt%, and an oxygen content of 0.06 wt% was obtained. Then put the material into the vacuum annealing furnace, and vacuumize to 8*10 -3 In the state of Pa, heat to 760°C, then introduce 0.03MPa argon, adjust the temperature to 860°C, and anneal for 2 days. Figure 9 It is the backscatter diagram of the sample of Example 2 of the present invention. It can be seen from the figure that in this embodiment, there ar...

Embodiment 3

[0055] The master alloy of Example 3 was prepared and smelted from rare earth Er raw materials with an oxygen content of 0.4wt%, and 30wt% Er3Ni recycled materials with an oxygen content of 0.8wt%. Put the master alloy in the crucible, vacuum to 7*10 before heating -3 Pa, then introduce argon gas into the crucible, the pressure of argon gas is 0.06MPa, and then melt the master alloy, put the molten master alloy at 1350°C, let it stand for 11 minutes, and then flow out from the crucible with holes, leaving There is a high oxygen content to spare. A sample of Example 3 with an Er content of 95.6 wt%, a Ni content of 4.2 wt%, and an oxygen content of 0.2 wt% was obtained. Then put the material into the vacuum annealing furnace, and vacuumize to 8*10 -3 In the state of Pa, heat to 740 degrees, then introduce 0.05MPa argon, adjust the temperature to 840 degrees, and anneal for 5 days. Figure 12 It is the backscatter diagram of the sample of Example 3. It can be seen from the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com