Radiation cross-linked low-smoke halogen-free flame-retardant locomotive oil-resistant electric cable material and preparation method thereof

A crosslinking type and cable material technology, applied in the direction of organic insulators, plastic/resin/wax insulators, etc., can solve the problems of low transmittance, heavy smoke, etc., achieve good low temperature resistance, improve oil resistance, and good phase capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Further elaborate technical characteristics of the present invention below in conjunction with embodiment:

[0024] The method of obtaining the radiation cross-linked low-smoke halogen-free flame-retardant locomotive oil-resistant cable material is as follows:

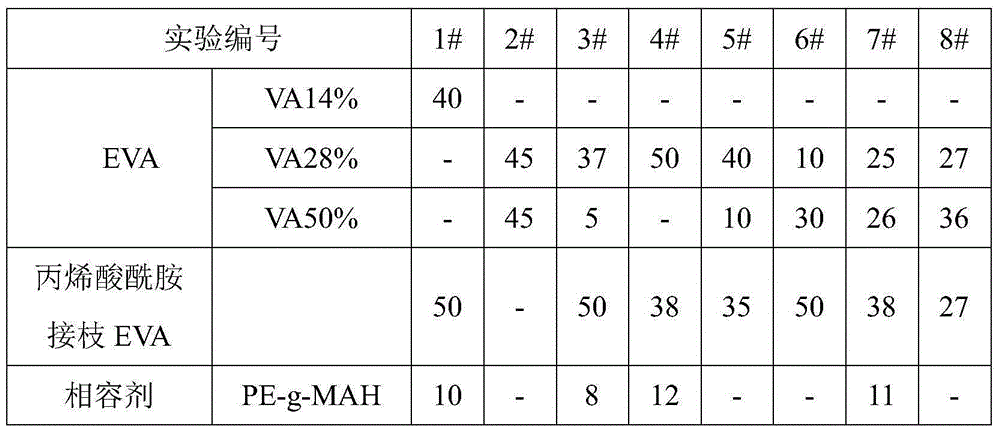

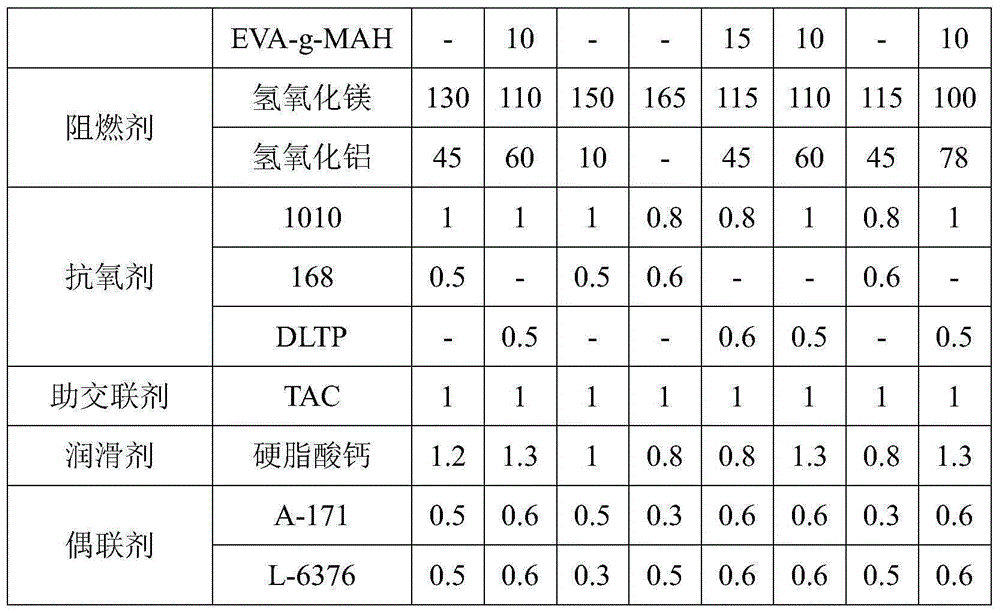

[0025] In the following preferred embodiments, weigh the raw material components according to the ratio in Table 1, place them in a high-speed mixer and mix them for 4-8 minutes, then put the mixture into the twin-screw for plasticizing and kneading, and then enter the single-screw extruder Granulate. The processing temperature of twin-screw is: conveying section 115-125°C, melting section 120-135°C, mixing section 130-145°C, exhaust section 125-135°C, homogenizing section 140-150°C, head 140- 155°C, including single-screw temperature: 130-140°C in the first zone, 130-145°C in the second zone, 140-150°C in the third zone, 145-155°C in the head, granulated and air-cooled before packaging.

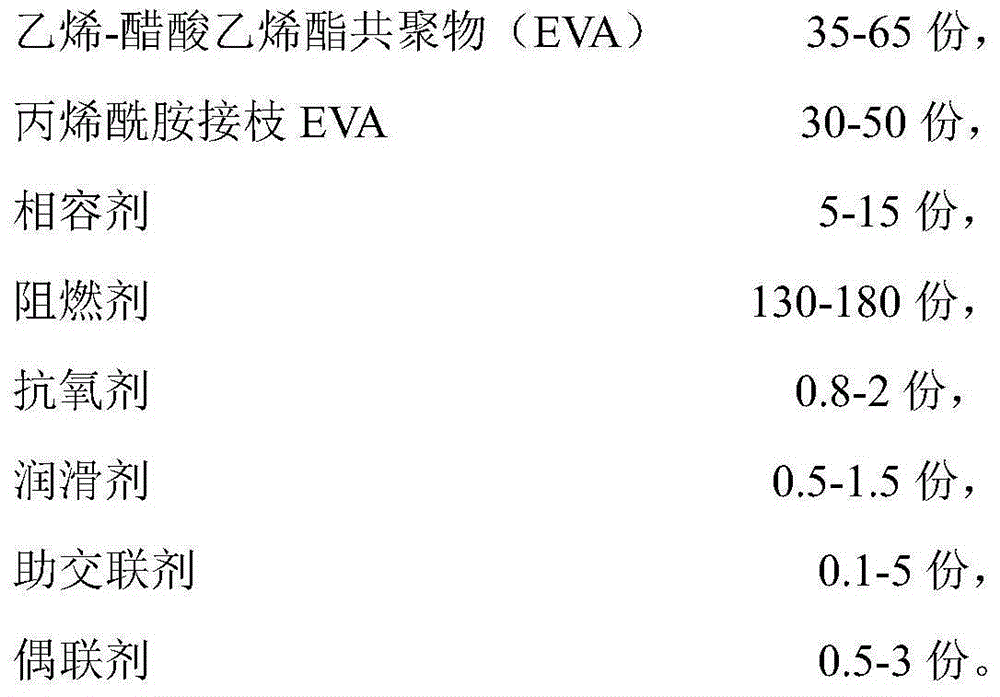

[0026] Table 1 is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com