Ingenol and preparation method therefor

A technology of ingenol and methanol, which is applied in the field of ingenol and its preparation, can solve problems such as environmental pollution, complicated steps, and human damage, and achieve the effects of reducing production costs, simplifying separation steps, and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

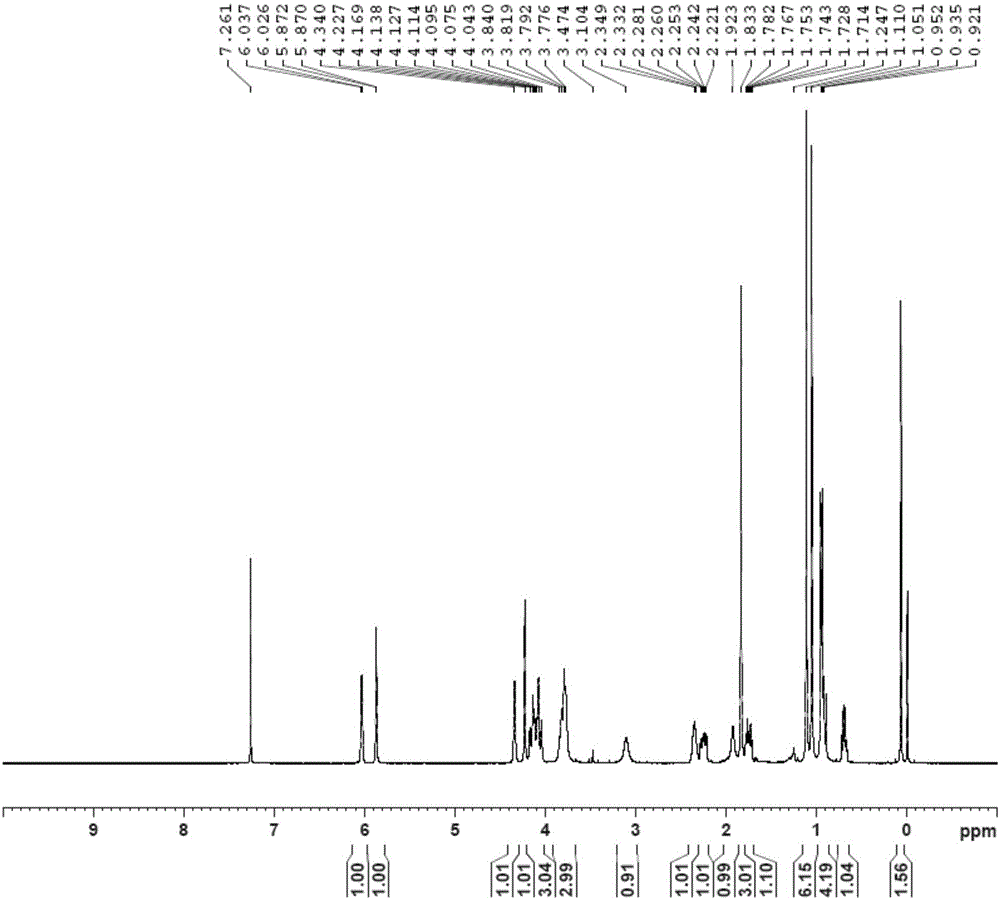

Image

Examples

Embodiment 1

[0058] In this embodiment, ingenol is prepared by the following method, which specifically includes the following steps:

[0059] (1) Pulverize 10kg caper seeds, add 30L industrial methanol solvent to the pulverized caper seeds, extract by cold soaking for 3 times, each time for 12 hours, combine the extracts, concentrate the extracts to 4L, reclaim methanol ;

[0060] (2) add 10L sherwood oil to the extract that step (1) obtains and extract 3 times, take the methanol solution of the lower layer, concentrate, and obtain about 220g of the concentrate;

[0061] (3) Add 2.2L0.1mol / L LiOH to the concentrate obtained in step (2) and stir for 15 hours. After the reaction, add 2.2L0.1mol / L acetic acid to neutralize, and then concentrate and evaporate to dryness to obtain ingenol-containing sample;

[0062] (4) Dissolve 220g of the sample obtained in step (3) in methanol, then mix with 220g of silica gel, grind evenly, dry, and carry out chromatographic separation. The column chroma...

Embodiment 2

[0067] In this embodiment, ingenol is prepared by the following method, which specifically includes the following steps:

[0068] (1) Pulverize 20kg caper seeds, add 60L industrial methanol solvent to the pulverized caper seeds, extract by cold soaking twice, each time for 12 hours, combine the extracts, concentrate the extracts to 4L, reclaim methanol ;

[0069] (2) add 20L sherwood oil to the extract obtained in step (1) and extract for 2 times, take the methanol solution in the lower layer, and concentrate to obtain about 440g of the concentrate;

[0070] (3) Add 4.4L0.2mol / L LiOH to the concentrate obtained in step (2) and stir for 12 hours. After the reaction, add 4.4L0.2mol / L acetic acid to neutralize, and then concentrate and evaporate to dryness to obtain ingenol-containing sample;

[0071] (4) Dissolve 440g of the sample obtained in step (3) in methanol, then mix with 440g of silica gel, grind evenly, dry, and carry out chromatographic separation. The column chromat...

Embodiment 3

[0075] In this embodiment, ingenol is prepared by the following method, which specifically includes the following steps:

[0076] (1) 50kg of caper seeds are pulverized, 150L of industrial methanol solvent is added to the pulverized caper seeds, cold extraction is extracted 3 times, each time for 12 hours, the extracts are combined, and the extracts are concentrated to 10L;

[0077] (2) Add 50L sherwood oil to the extract obtained in step (1) to extract 3 times, take the methanol solution in the lower layer, and concentrate to obtain about 1100g of the concentrate;

[0078] (3) Add 11L0.4mol / L LiOH to the concentrate obtained in step (2) and stir for 10 hours. After the reaction, add 11L0.4mol / L acetic acid for neutralization, then concentrate and evaporate to dryness to obtain a sample containing ingenol ;

[0079] (4) Dissolve 1100g of the sample obtained in step (3) in methanol, then mix with 1100g of silica gel, grind evenly, dry, and carry out chromatographic separation....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com