Coal Chemical Wastewater Treatment Process

A technology of sewage treatment and coal chemical industry, applied in the direction of oxidized water/sewage treatment, water/sewage multi-stage treatment, light water/sewage treatment, etc., can solve the problems of long time consumption, low removal rate, large energy consumption, etc., to reduce Time consumption and energy consumption, the effect of improving the ease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

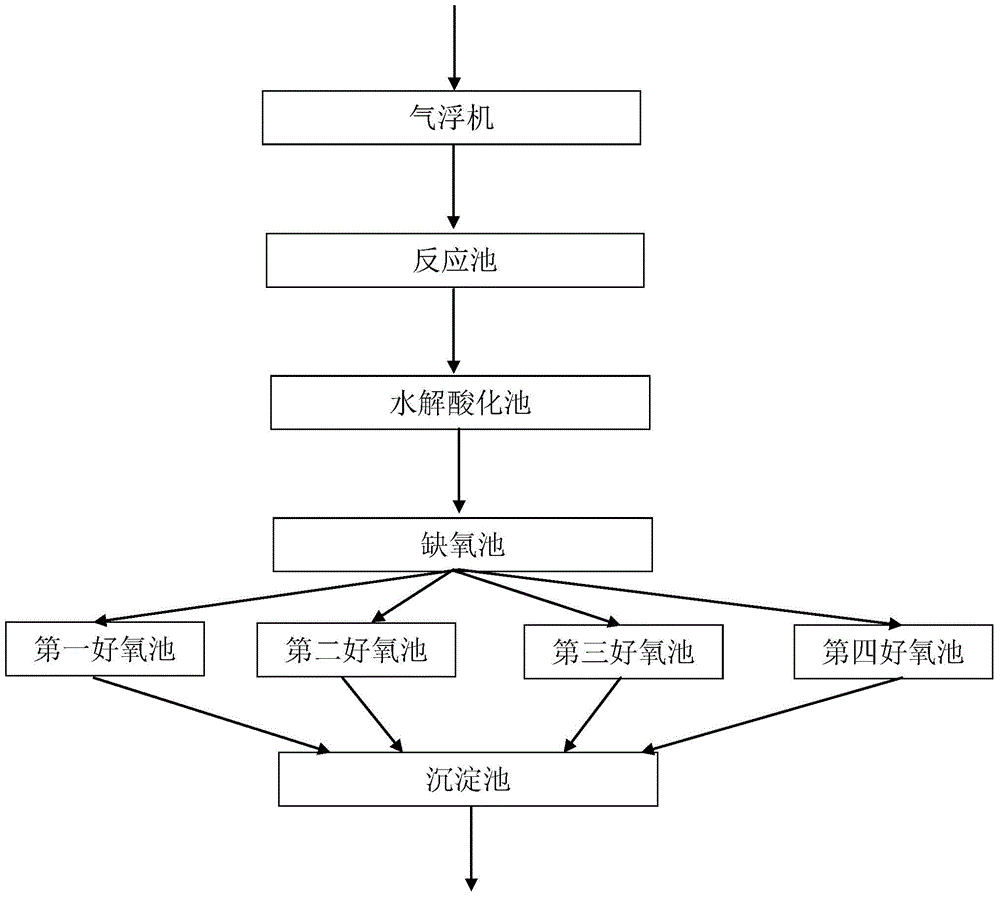

[0039] A coal chemical wastewater treatment process, such as figure 1 As shown, including the following steps:

[0040] Step 1: Pour the coal chemical wastewater into the air flotation machine, and add polyaluminum chloride to the air flotation machine, air flotation treatment for 20 minutes, and then remove suspended solids;

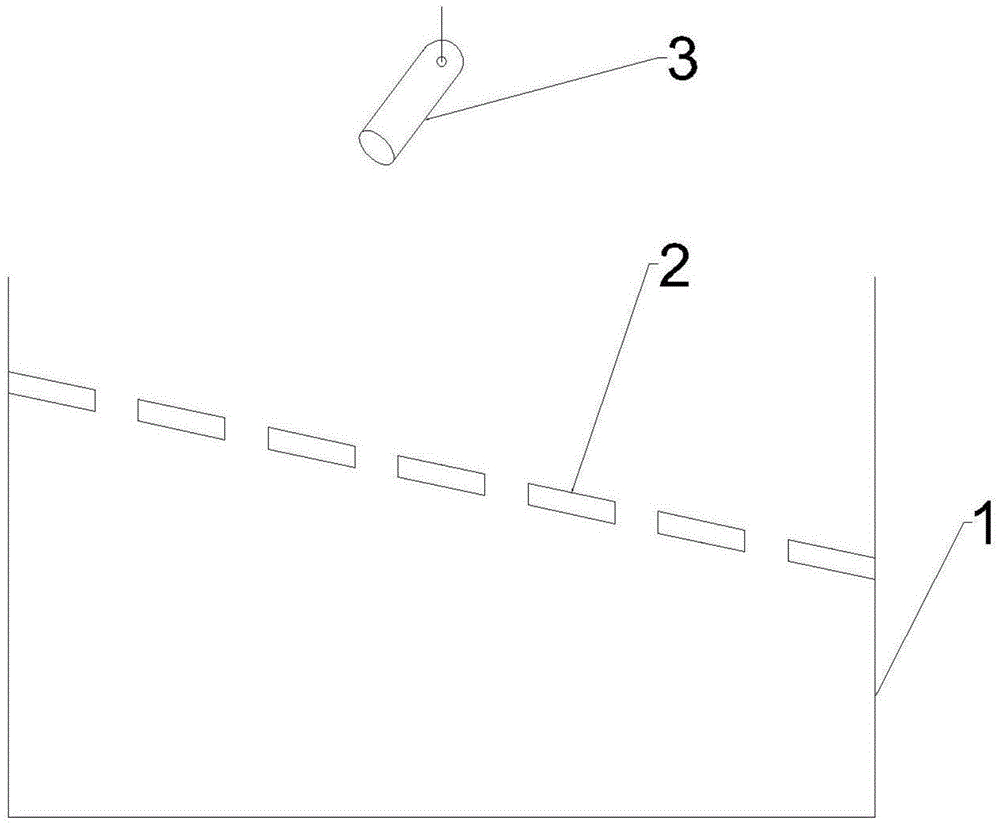

[0041] Step 2: Make the coal chemical wastewater treated in step 1 flow into the reaction tank. The hydraulic residence time in the reaction tank is 100 minutes, and ozone is intermittently fed into the reaction tank to control the ozone in the coal chemical wastewater in the reaction tank. The content is 10 mg / L; wherein, a ceramic sieve plate is provided in the middle of the reaction tank to divide the reaction tank into two upper and lower spaces, the ceramic sieve plate is evenly loaded with a titanium dioxide coating, and the ceramic sieve An ultraviolet lamp is arranged above the plate, the ultraviolet lamp is driven by a motor, and the motor drives th...

example 3

[0052] A coal chemical wastewater treatment process includes the following steps:

[0053] Step 1. Pour the coal chemical industry sewage into the air flotation machine, and add polyaluminum chloride to the air flotation machine, air flotation treatment for 30 minutes, and then remove the suspended matter;

[0054] Step 2: Make the coal chemical wastewater treated in step 1 flow into the reaction tank. The hydraulic residence time in the reaction tank is 120 minutes, and ozone is intermittently fed into the reaction tank to control the ozone in the coal chemical wastewater in the reaction tank. The content is 15 mg / L; wherein, a ceramic sieve plate is arranged in the middle of the reaction tank to divide the reaction tank into two upper and lower spaces, the ceramic sieve plate is evenly loaded with a titanium dioxide coating, and the ceramic sieve An ultraviolet lamp is arranged above the board, the ultraviolet lamp is driven by a motor, and the motor drives the ultraviolet lamp t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com