Bottle washing clamp, bottle washing machine and quick change method for bottle clamping blocks

A bottle clamping and bottle washing technology, applied in cleaning methods and appliances, chemical instruments and methods, bottle filling, etc., can solve the problems of inability to quickly replace the clamping block, low efficiency, and complicated replacement methods, and achieve rapid replacement, The effect of high efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention are described in detail below:

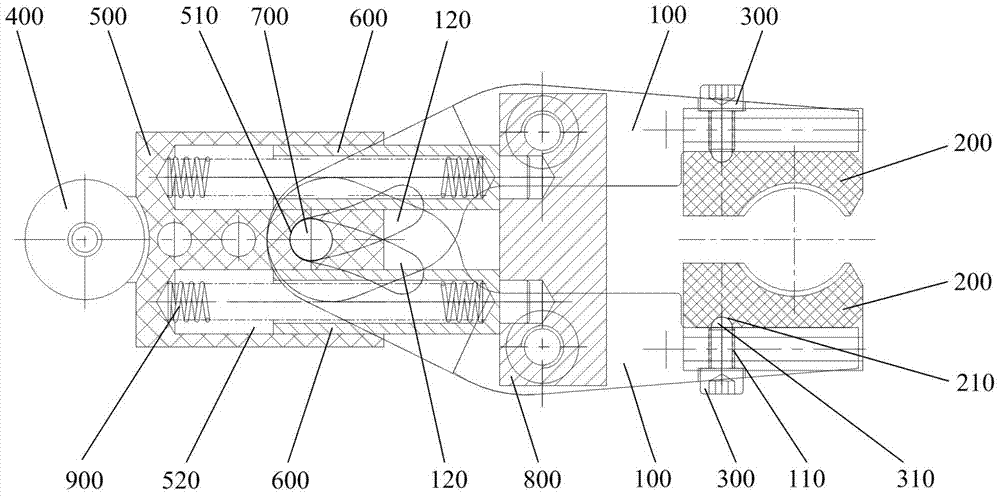

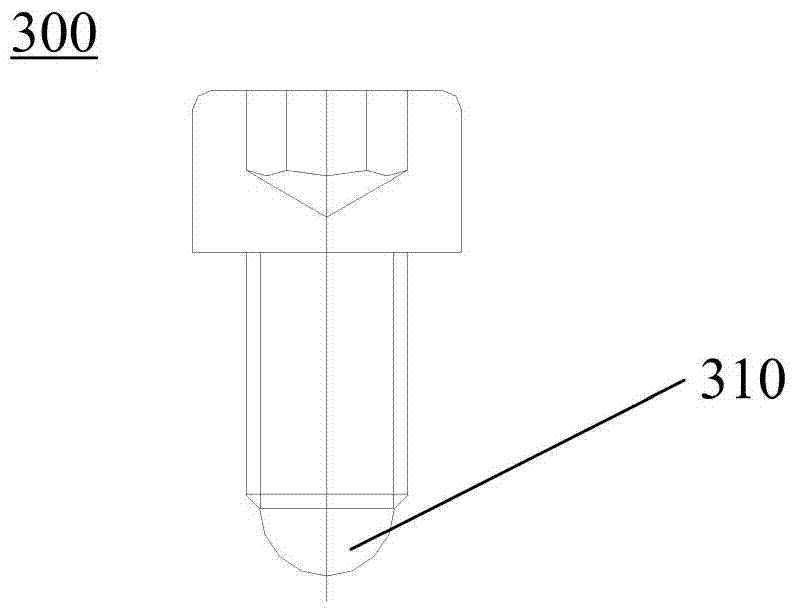

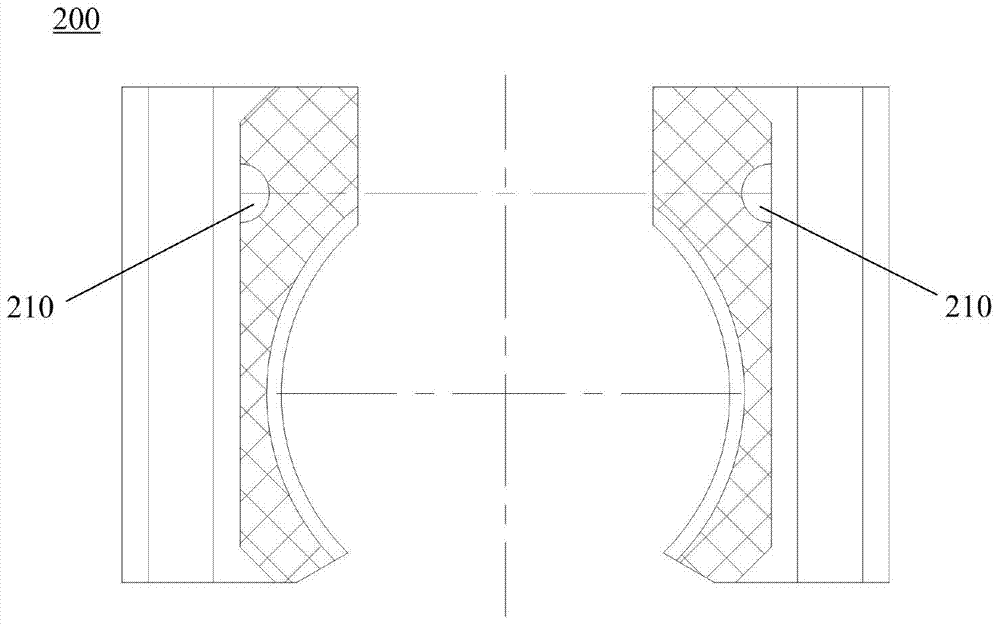

[0033] figure 1 It is a cross-sectional view of the bottle-washing clip according to the embodiment of the present invention, specifically, a cross-sectional view cut along the transverse direction of the bottle-washing clip. Such as figure 1 , figure 2 As shown, a bottle washing clip includes a movable block 100, a bottle clamping block 200 and a positioning piece 300. The tail end 310 of the positioning piece 300 is in a convex shape whose outer wall is a curved surface. The movable block 100 is provided with a positioning The through hole 110, the bottle clamping block 200 is provided with a groove 210 matching the tail end 310, the positioning member 110 is inserted into the positioning through hole 110 and the groove 210 in turn, the movable The block 100 is slidably connected with the bottle clamping block 200 and positioned by the positioning member 300 . Preferably, the positioning member...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com