Ceramic tile powder distribution method

A ceramic tile and cloth technology, which is applied to supply devices, manufacturing tools, etc., can solve the problems of inability to form block texture and small powder size, and achieve the effect of simplifying block texture process and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

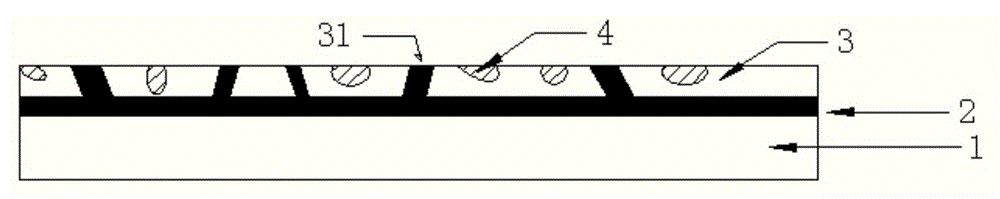

[0030] This embodiment provides a method for distributing ceramic tile powder material, which includes the following steps:

[0031] Step 1: Sprinkle the well-known ceramic tile fabric on the fabric belt to form a fabric belt. Set a conveyor belt on the fabric belt. The blanking port of the conveyor belt is located directly above the fabric belt, and the granular powder is applied to the conveyor belt. , Then carry out rolling treatment to form a granular powder cake, then crush the granular powder into lumps, and finally apply the lumps on the fabric belt;

[0032] Step 2: Distribute the well-known ceramic tile base material, and then transfer the powder material through the grid fidelity to the press to form a brick blank, completing the entire distribution process.

[0033] The ceramic tile fabric used in step 1 is a well-known component, that is, clay, feldspar, sand, etc. are used as main raw materials, and colors or additives are added according to different decoration needs an...

Embodiment 2

[0039] In order to further enrich the decorative effect of ceramic tiles after cloth, the tile surface has a striped decorative texture with obvious effect and wear resistance. The following methods can be used for cloth.

[0040] A method for distributing ceramic tile powder materials includes the following steps:

[0041] Sprinkle the well-known ceramic tile fabric on the cloth belt to form a fabric belt. Set a conveyor belt on the cloth belt. The blanking port of the conveyor belt is located directly above the cloth belt. The granular powder is applied to the conveyor belt. Rolling treatment to form a granular powder cake, then crush the granular powder into lumps, and finally apply the lumps on the fabric belt;

[0042] Step 2: Roll the fabric tape to form a fabric cake, and then cut the fabric cake to make it into a brick-like fabric blank;

[0043] Step 3: Vibrate and crush the fabric blank to make the fabric blank form a plurality of penetrating ravine textures;

[0044] Step 4...

Embodiment 3

[0056] In this example, the basic scheme is the same as in example 3. The difference is that after step 3 and step 4, the process of step 3 and step 4 is repeated once, and the texture material used in repeated step 4 is the same as before. The difference of giving at one time. Through this treatment, the decorative effect can be further enriched. In this embodiment, the main color of the fabric is yellow powder, the texture material applied for the first time is the powder material with opacifying effect after burning, and the texture material applied for the second time is After burning, it is silver-gray powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com