Heavy bamboo composite flooring production technology

A composite flooring and production process technology, which is applied in the jointing of wooden veneers, manufacturing tools, wood processing appliances, etc., can solve the problems of unscientific and reasonable production process of bamboo flooring, poor quality of bamboo flooring, etc., and achieve product quality Better, better-looking, and easier-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

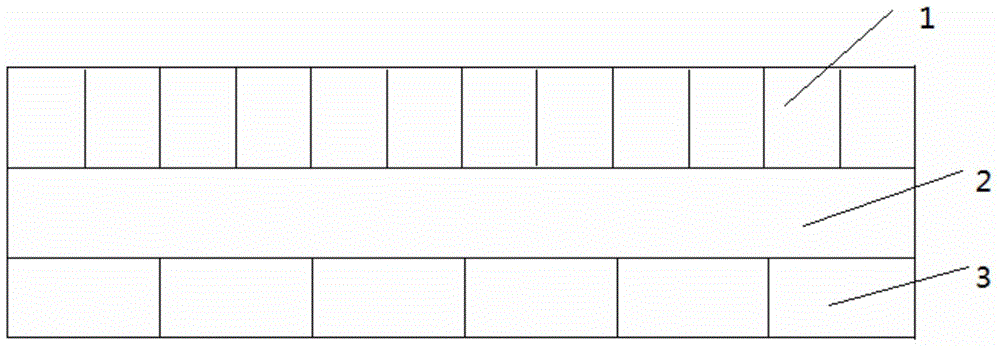

Image

Examples

Embodiment

[0017] Embodiment: a kind of production technology of heavy bamboo composite floor, comprises the steps:

[0018] Step (1), the processing of heavy bamboo: first break the heavy bamboo into heavy bamboo slices, and remove the green and yellow surface layers; Put it into the carbonization furnace for carbonization treatment, put the carbonized bamboo silk into the dryer and dry it until the moisture content of the bamboo silk drops to 7% to 8%; place the dried bamboo silk in a dry room at room temperature , keep the body for at least 15 days; finally take out the bamboo strands, apply glue, put them into the mold, and use a press to press the bamboo strands into heavy bamboo squares; ; Glue choose EO grade glue, such as modified uric acid resin, which has the advantages of environmental protection and non-toxicity. When breaking the heavy bamboo boards, it is mainly to break the heavy bamboo boards into boards of different thicknesses and widths according to the various needs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com