Clamp for large spherical casting multi-hole multi-plane same-direction machining

A large-scale casting, multi-plane technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of waste of manpower, unstable clamping, long processing period, etc., to avoid uneven force, shorten Processing cycle, the effect of ensuring processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

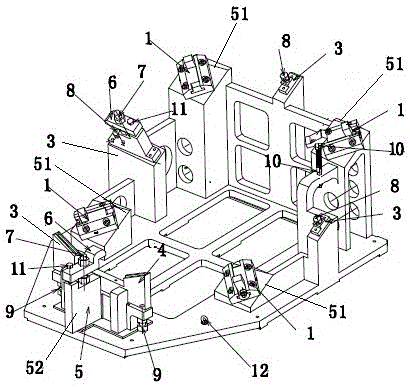

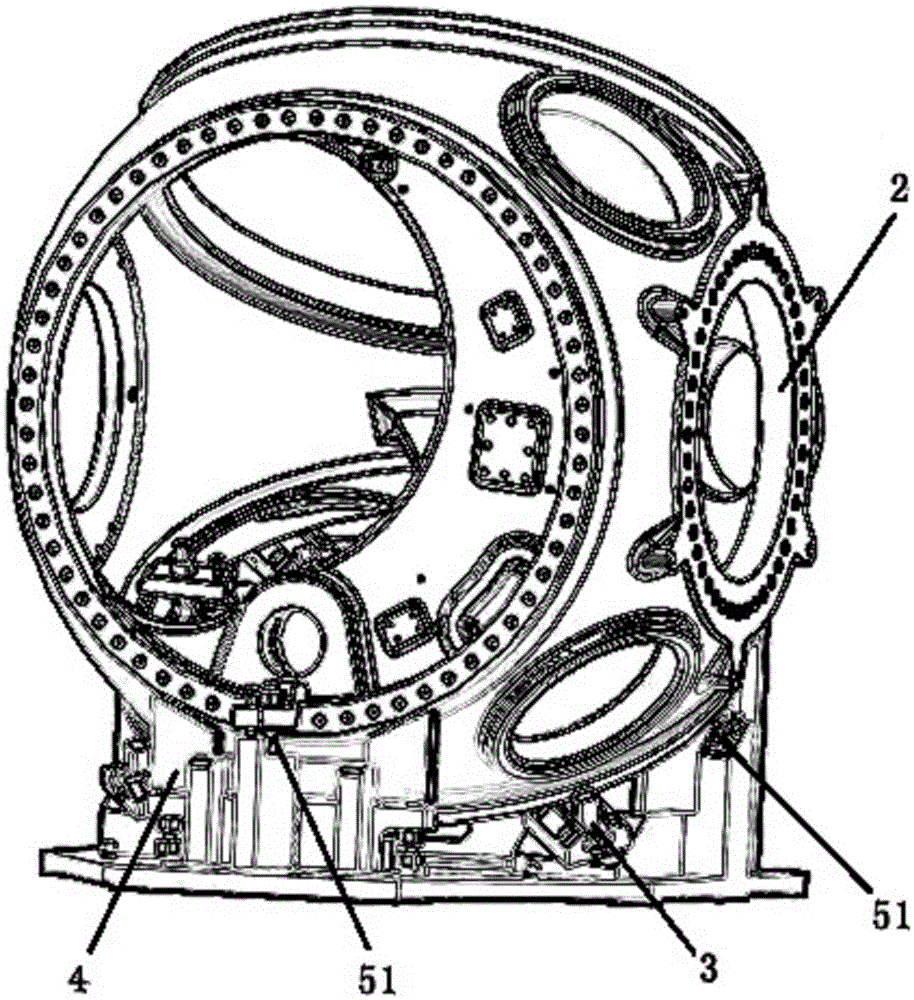

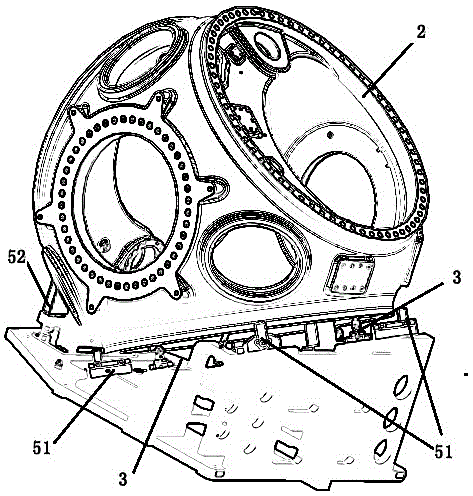

[0019] Such as figure 1 As shown, the jig for large-scale spherical casting porous multi-plane processing with the same orientation includes a V-shaped support body 5 arranged on the skeleton, and at least three angle supports 3 alternately arranged between the support seat 51 and the end support seat 52 The V-shaped support body 5 includes at least two groups of respectively symmetrical support seats 51, and an end support seat 52 which is arranged on the symmetrical axis of the two groups of respectively symmetrically arranged support seats 51 and is located at one end thereof, and each group of mutually symmetrical The heights of the support bases 51 are the same, but the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com