Automatic assembly equipment for guide rod and assembly method of automatic assembly equipment

An automatic assembly and guide rod technology, which is applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of low assembly efficiency, easy fatigue of assembly personnel, and high product scrap rate, so as to reduce labor difficulty and intensity and improve assembly Product quality, the effect of simplifying manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. As a part of this specification, the principles of the present invention will be described through examples. Other aspects, features and advantages of the present invention will become clear through the detailed description. In the referenced drawings, the same reference numerals are used for the same or similar components in different drawings.

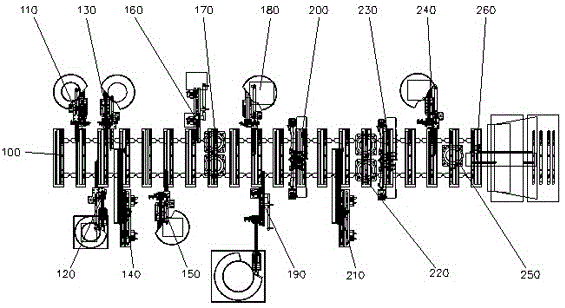

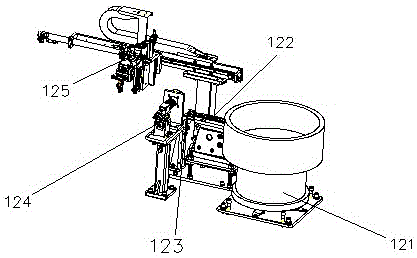

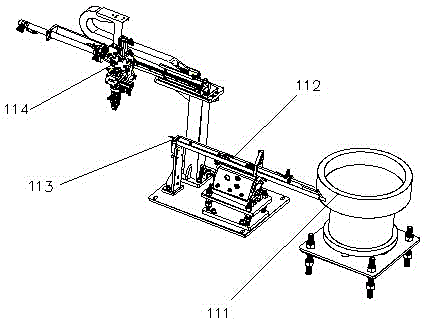

[0049] Such as Figures 1 to 13 As shown, the structure schematic diagram of the automatic assembly equipment of the guide rod and each device in the preferred embodiment of the present invention, the automatic assembly equipment of the guide rod of the present invention can assemble circular rivets, L-shaped parts, oval parts, square rivets, plastic parts, eccentric Rivets, long steel bars, washers, stoppers, racks and other parts are automatically assembled together, and the whole process is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com