Copper and sulphur separation method for copper-sulphur ore

A copper-sulfur separation and copper-sulfur technology, applied in solid separation, flotation, etc., can solve the problems of high irritation, easy loss of molybdenum, and high alkalinity of tailings water. Effects from a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

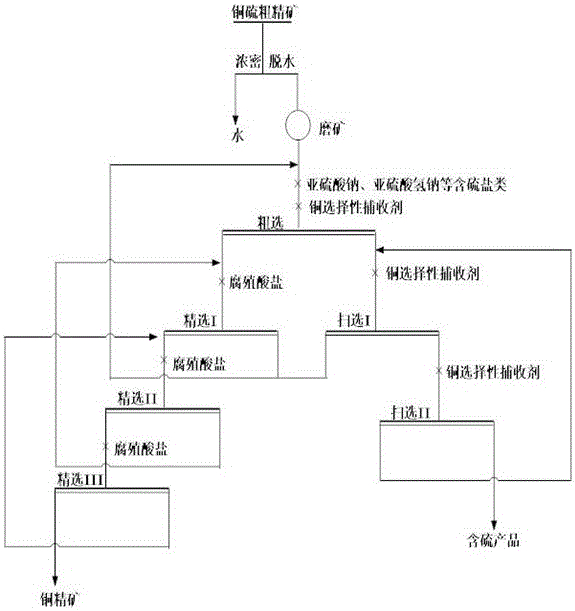

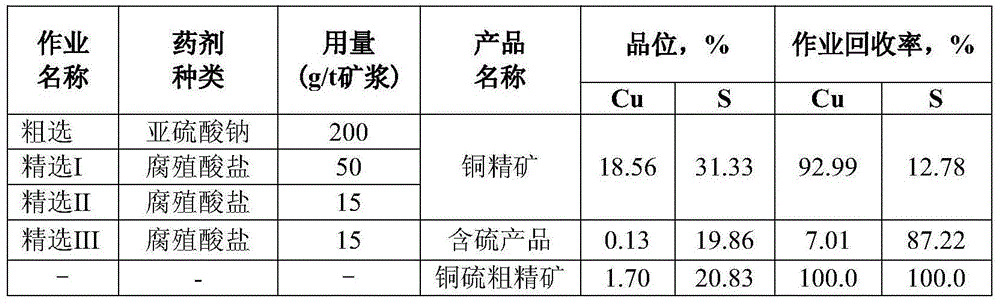

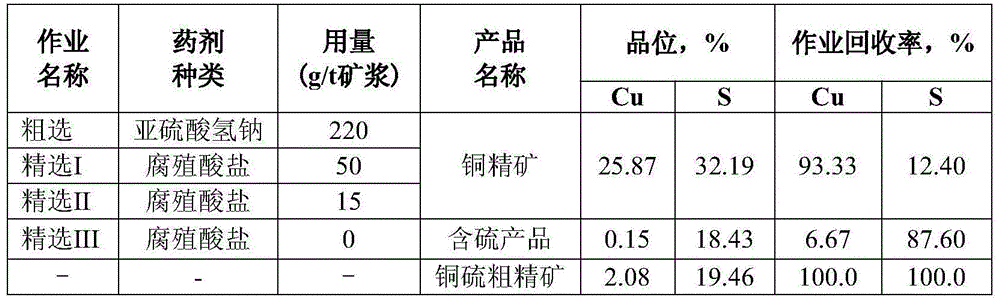

[0054] Copper-sulfur rough concentrate obtained by flotation of copper-sulfur ore, through thickening, dehydration, and regrinding, uses sodium sulfite to eliminate the influence of copper ions, forms a reducing atmosphere on the pulp, and inhibits the formation of pyrite; realizes pyrite through humate Further suppression, so as to realize the lime-free separation of copper-sulfur ore, the method specifically includes:

[0055] Copper-sulfur coarse concentrate regrinding treatment: thicken and dehydrate the copper-sulfur coarse concentrate obtained by flotation. 95%-0.043mm.

[0056] Sulfur suppression treatment: dilute the concentration of the grinding product to 10%-25%, add sodium sulfite (or sodium pyrosulfite, or sodium bisulfite, or sodium thiosulfate) for stirring, and the ratio of dosage to pulp weight is 0.05-0.5:1000 , the reaction time is 2min to 5min, the sulfite radical reacts chemically with the copper ions in the pulp (sodium metabisulfite, sodium bisulfite, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com